Need help with costing, when we do a setup on a machine we are setting the machine up to run a group of very similar parts and the initial setup takes the most time, usually 12 to 18 hours. Then when we change from one part to another similar part the setup time is less, 3 hours for changeover. Is there a way in costing to apply the initial 18 hour setup cost to all pieces made during the run of similar parts. Lets say im running 2,000,000 pieces on a total of 10 different jobs and the first setup is 18 hours and costs $2,000, i want .$001 per unit of initial setup costs applied to each piece on the run.

You can clock into more than one job at a time and the time will be divided between the jobs (if you resource group settings are correct). So the set-up guy would have to clock into the 10 different jobs.

The mass clocking in/out can be handled with the work queue (try this first) or UI customization on a dashboard.

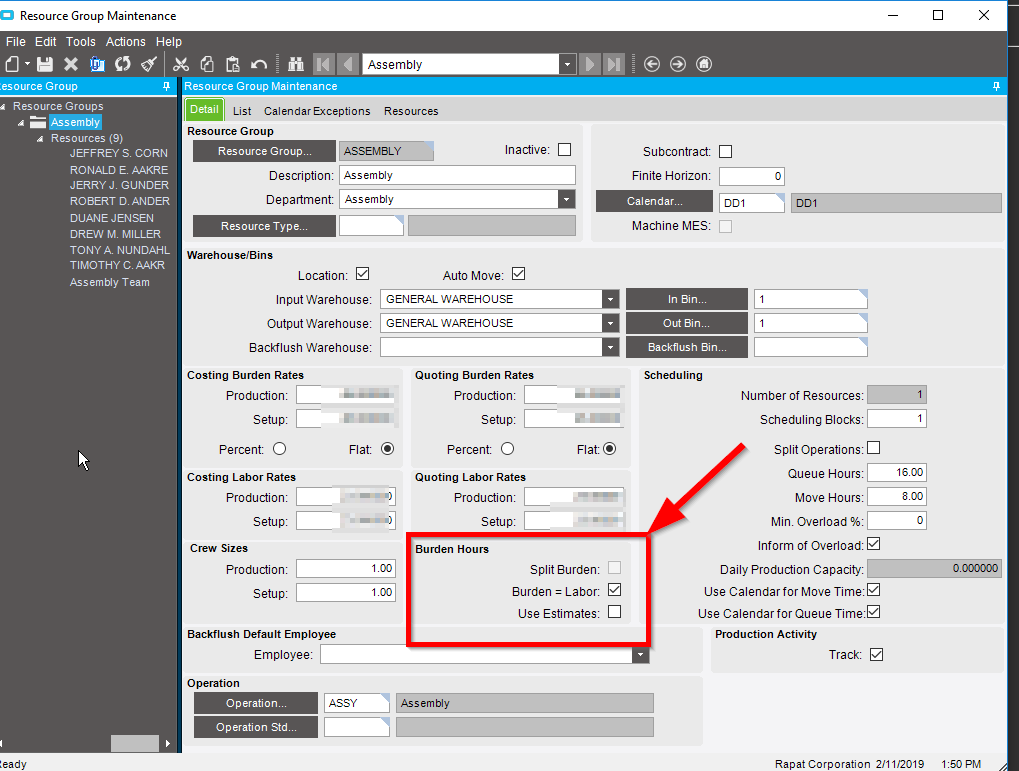

I can’t remember exactly what each check box does (so make sure you test), because once we had them correct to our business, we didn’t mess with them, but the split burden, and burden = labor has to be set correctly or else it will think you are running multiple machines if you are clocked into multiple ops.

See this thread for some discussion about those settings.

Thanks