Are those parts STDcosted? If so I’m guessing for Co-Part to work nicely you would have to be running AVG or LotAvg. Sorry if you said what it is already only half paying attention.

I am standard and I don’t know if I was really that clear about what costing method I was using.

Yes, both parts are standard costed using a method that doesn’t involve co-parts because that’s how we typically run it.

The whole goal of this is to show favorable variances for each part because this job is splitting costs which means both benefit… the question is how do I create a job to do that…

I still don’t think it will work because your MOM is not set up that way.

Have you tried cutting both jobs and then batching them?

John, my man, does batching allow you to data collect on one job and have costs distribute to both?

I don’t think it works that way. Everywhere else, it only uses what’s on the job. After you do your initial copy from the master, you have carte blanche to do whatever you want to it. I don’t believe co parts wouldn’t do the same thing, and for some reason go back to the master to get the details. You should be able to change it on the job. Now, I could easily be wrong, but it seems counter to how jobs work with everything else.

Love that you guys are so into this and on the same page, I can tell y’all got exactly what I am trying to do.

Out of curiosity, Does the standard costs plus the (one) variance add up the total job cost?

It might be possible that epicor assumes the co-part to always be a co part and thus doesn’t put a variance on it. (not likely, but I don’t really know what I’m talking about with co-parts)

Speak freely man, I don’t know either!

Yes. Assuming they have the same exact operations.

Yes the standard cost plus the favorable variance (-$$$) adds up to the total job cost. That’s all coming out fine, but as you know, costing is all about the details… and the reality is, both parts benefitted from splitting the costs, but the variance is only booking to one part.

Reaaaaaaallllyyyy… interesting man. This might be the way to go, but I am still perplexed about this whole co-part yield thing. Cause I would expect that the costs get split accordingly and therefore would result in a variance when both these parts are costed using the full cost of the material o the job yet the way I have the yield split, they both benefit and would come in UNDER that cost.

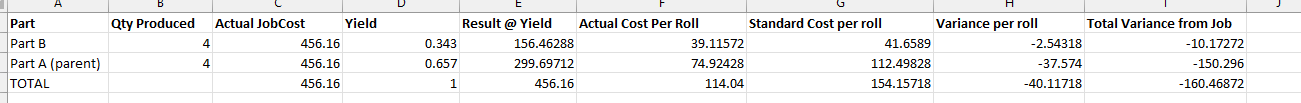

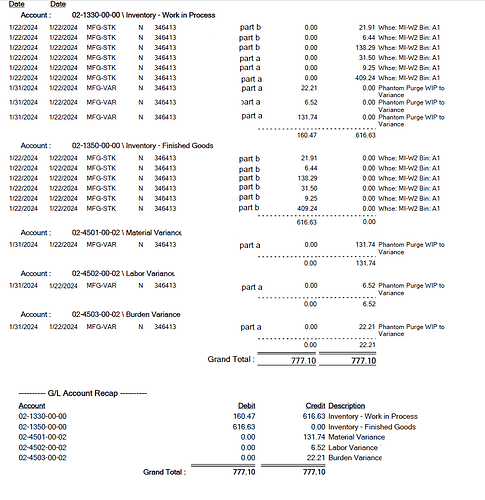

Look @jkane @Banderson the below excel shot is exactly what I expect to happen, yet when you look at the INV/WIP section for my variances on this job you can see them all allocated to PART A instead of split out how they should be.

The fact of the matter is, the variances are being calculated using yields, the engine is correctly identifying that the costs were split and that there is a favorable variance of 160.47 (you can see this by adding up the variances in the INV/WIP report and compare it to my variances in the excel sheet), but it isn’t allocating it appropriately between the co parts. Why?

I definitely do not know the answer to your issue. So, grain of salt.

I think it will not work because the co-part is not defined in the MOM. Just basing this off of gut feeling. I’m having trouble explaining why, but it just makes sense in my head.

Try setting up the co-parts in the MOM and then see what happens.

Oh I’m onto that next… already spent half a day trying to wrap my head around this.

There are some interesting things with coparts. If you have scrap, you can only report it against the main parent copart. So, I am making an assumption that the total variance is being applied towards the main copart too. The only thing that seems to go right in costing is the splitting of the material cost and the labor cost, otherwise, it all falls to the main parent copart.

I would try batching the two separate jobs. It should split your material and labor like the copart job does and it might split the variance as well.

Love all of you for taking the time to think this through with me.

Thank you so much.

That’s two votes for batching jobs… I think I will explore that next.

I still wonder though if I actually went through creating a method with a co-part, would that help this in any way… Not sure though.

Only 1 way to find out!

You are quickly learning @utaylor that the idea of Co-Parts is fabulous the execution of Co-Parts is dodgy and confusing LOL.

We had to FAFO to get our roll slitting to work since a pound is a pound but the individual co-parts coming off had different weights and the cost distribution would follow. We would end up with a roll of paper going in at 50/lb and one part coming out at 75/lb and the other at 25/lb… a pound is a pound. That is where we had to learn to bastardize the Material/Labor cost factors and use them to distribute as a percentage of the parent.

If I start with a 30 inch roll of paper and I cut a 12 and a 14 inch roll I would enter 400 for the 12 and 467 for the 14 and that remaining 14% goes to variance and my rolls come out within 1cent/lb of each other.

That’s the extend of my knowledge of co-part in our context. The paper rolls are avg. Not at all how the system was intended to be used but with many hours of trial and error the end we reached.