Is there a way to get sales order information to flow down to not just the part being purchased but any jobs or supplier POs for lower-level parts used to make the part being purchased? Without changing them to make direct parts?

If a job is make to stock, how would you know which finished parts from the job are pulled for a specific order.

If the job’s demand is for an order, then you should be able to get that order info into the job. And you can have a defined mfg’d part be “made to order” even if it is qty bearing.

The way that it’s been explained to me is that, if I’m making a refrigerator for example, if the entire thing is for customer ABC, sales order # 12345, the fridge handle job, the panels, etc. will not carry down that customer name and sales order # 12345 even if the demand for them is coming from sales order # 12345, because they are not checked as make direct in Part Maintenance. Only the entire refrigerator job will show customer ABC sales order # 12345.

Is this not correct? How can I get that information onto all of the jobs?

If the handles and other parts are pulled as materials, then there’s kind of a disconnect. If they are jobs from ASM’s in the refrigerator job, there may be a way to link them.

In other words, if the job to make handles is just to meet demand (usage in the fridge jobs + Min Stock+…), then that job isn’t really making them for a specific use. Although you could possibly derive what fraction of the job is to meet the demand for the fridge job.

And what info in the order do you need to appear in jobs or PO’s? You just trying to make sure that all the parts for the finished fridge are planned / on order? And that you don’t count the same part for two different fridge jobs?

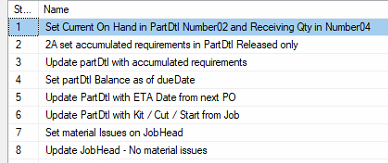

I calculate supply jobs for our order review. It is a multi step process and I am not on 10 yet, but will be writing this soon there. The process moves the data based on PartDtl like a timephase.

You calculate the quantity available of each sub part using the requirement flag to know whether you are adding or subtracting and store it in a ud table.

Then you read the ud table for the part on the parent job and if the quantity is positive then you look backwards from that date to find the job that will produce that component.

Hi Greg,

We are faced with the same problem for many years now. With a new ops manager begging for help it’s been brought anew to my attention. Would you mind taking some screenshots of how you are handling this? A picture would be worth a 1000 words! Our problem is the same, top level make to order job, a few layers of component jobs below it. We push out a job for a component and have no idea what effect it has on upper level parts / top level with no obvious data ties.

Thanks so much for your consideration!

Nancy

@gpayne, not sure I am completely understanding.

Perhaps you can explain how this is different from Multi-Level Pegging, as it kinda sounds like that, but not quite.

I’ll start putting together screen shots. The basic steps in the SQL job are below. @Rick_Bird It runs a time phase for each job material on released jobs, so somewhat like multilevel pegging. Then compares the available quantity on the material due date for that material. If the quantity is negative then it gets the next PO that will fulfill the entire shortage, not necessarily the next PO of any quantity.

I don’t look at supply jobs, but I think the theory would be the same as POs.

Another thing I recently did was an idea from @Beth to add a soft link on the make to stock tab for the order this make to stock is fulfilling. If the component jobs held a list of jobs they were supplying that could also be used for an alert that job X that supplies job Y has a new due date past the material required date of job Y. The sql job would only get this once per day, but a link could be used in a real time alert.

Greg

Hi Greg,

Thank you so much for your details and the link by @Beth.

We have some people clamoring for the same method used by you and Beth and others (@aholmes) to tag the make to stock with a related sales order release. It looks like some do experience a few difficulties with multiple orders but one make to stock and maintenance/entry of data as needed.

Any other downsides nobody mentioned? It could easily provide a nice list of jobs that can be reviewed on scheduling board together.

Also, we have not used make to job in the past much due primarily to concerns RE the job not pulling from stock when we have parts in inventory; however, it sounds like Auto-consume stock might work for that. Any experience there?

Also, I wonder about the accounting flow for the make to jobs. I think we’ve had concerns about whether the correct part cost gets put on a job. We use standard cost, so the part made to stock uses that when issued to job. We’ve generally only used make to job for one time parts so far…

I truly appreciate the feedback!

Nancy