That’s amazing that the two are so close. That’s within 800 PPM.

Yeah for all of that, with one UOM class you could eliminate LBFT1 and just have a part-specific conversion of LB to FT. Then you don’t get all of these weird hybrids.

(Our weird one is LB-FLD because of a vendor selling a liquid [fluid] in pounds. We have used it 4 times in three years. And I’m looking now and it’s a POTF, so why did I bother creating a UOM, and I am going to scream now…)

A similar one for us is epoxy. the components are sold by the LB, in a drum. We use them by volume as most don’t have significant expansion, to the volume to fill is easily calculated, and translates to the volume needed.

We have some standard part classes like weight, length, area and then a custom UOM class called Poly. Poly is our default class for everything we sell. In this class we have UOMs called EA, RL, CS, LB – where EA is the base UOM in this class. All other UOMs are part specific so 1 RL can be equal to 100EA,200EA depending upon the part. Same goes with CS. This has worked very well for us since we went to Epicor about 9 years ago.

With a custom class the advantage is that we do not have to define a conversion factor for all the UOMs in the class, only the ones that apply to the part.

So, in the case of milk there could be custom UOM class called MILK with Litre and LB as UOMs, with conversion factor specified as required either by part or fixed on the class itself.

Vinay Kamboj

I’m going to chime in on this one. It depends on what your raw materials are that go into making your finished goods; how you purchase them, how you store them and how you use them.

We have resin that is used in making our parts. Resin is used in grams but purchased in pounds which falls under the class of Weight. We also have components that go into making the parts and they are purchased in multiple Units of Measure but all are of the class Count (each, box of 50, box of 100, pack of 25, etc.). These are straight-forward.

Then we have other items that are not as straight-forward: Pad Printing ink is purchased in Liters but used in Grams. Each liter of ink (different colors) has a different weight. So, Liter falls under the UOM class Volume, but the use of the ink is in a different class, Weight. We use a part specific UOM to tell how much weight is a container of ink.

Hopefully this makes sense to you. For our tooling area, there is also the UOM for Length.

If you can get away with one UOM class, consider yourself lucky!

@Vinaykamboj I was waiting for someone to finally mention custom classes as I was reading through.

I actually really like the UOM Class. It works well when thought is actually put into the requirements.

I’ll ask the same question that I asked Mark - how do you do the conversion? AFAIK, even part-specific conversions can only happen within a UOM class, no?

Is it not a choice? I mean, you invent every UOM at setup. You could just abandon all classes except one and throw LB, GAL, FT and EA into the Area class if you wanted.

My curiosity is, what is the advantage to separate classes? Making the drop-downs shorter? Regulations?

@JasonMcD I use the Classes as a way of making sure the correct UOM is selected since there can be a few ways of storing/using resin (pound, ounce, gram, etc). If it is a new resin part number that is being set up, the buyer must choose a UOM in the UOM class of Weight. Our UOM class defaults to Count and UOM of EA (each) for a new part. If a buyer doesn’t change the UOM class to Weight, the BPM triggers to tell them to change it before saving. It also helps organize UOMs.

As for the Pad Printing ink, the UOM conversion is done in Part Maintenance on the UOM tab. It’s tricky but once you do a few of them, it starts “hitting home” how it works. My problem is that I don’t do enough of them so I have to “refresh” my brain everytime I need to set one up. The buyers usually call me to help when they run across one of these

I would think the main advantage to separate classes is to prevent using incompatible UOMs.

I can’t think of ever buying eggs by the foot. Yet

- 1 EA = 1 IN

- 12 IN = 1 FT

- 12 EA = 1 DZ

therefore 1 DZ = 1 FT

I can’t picture how to do that if the UOMs are in different classes. I only get a list for one UOM class, the one assigned to the part.

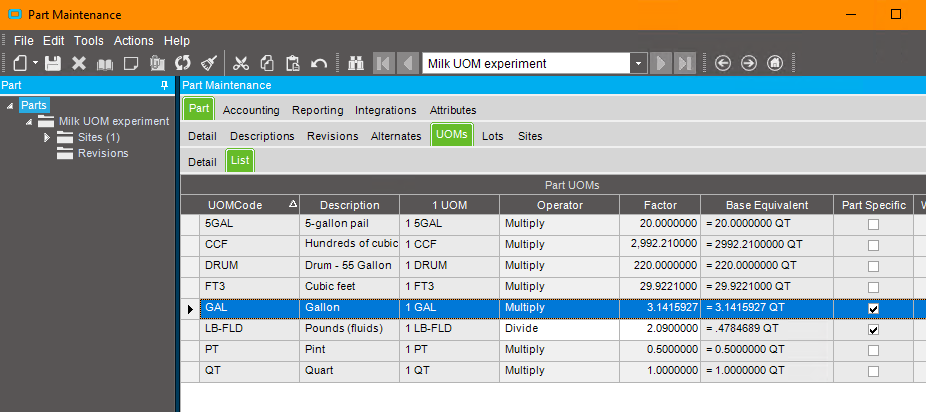

(I made GAL part-specific in test only, if you are wondering.)

I like the conversion… easy as pie.

Also, a cylinder of radius z, and height a, has a volume of pizza

Jason, you need to create a “special” part class that contains both part classes. I’ve had to do that. Which is why it would be nice to have one part class. Unfortunately, as I pointed out earlier, in my case there are BPMs that use the part class for actions.

are you sure, since this are after all milk products, that it isn’t really a wheybridge?

Careful, some people get mad when you take puns whey too far.

No whey. I can barley believe you even said that.