You could use a UD table with a BPM to auto-increment a tag number with the job number and a suffix. For example, if the job number was 12345, the tag numbers could be 12345-1, 12345-2, etc. If the tag number had a barcode on the physical tag, it then is scanned at receipt to inventory as the lot number.

Hi Dave,

One thing not yet mentioned-what is the actual processing requirement or purpose of this label, what’s it use case?

I agree with the idea of a limited customization for a ud lot field if really necessary, and that value’s purpose and attributes should be defined to know what combinations of values or uniqueness is necessary. We use 2D barcodes to drive a few processes and combine key operational values as the content and then parse those values in following steps as needed? What values would be necessary or helpful in the following ops? And also think about partial completion records, recovery for mistakes and any retention needs for things like auditing, performance analysis, etc. these are a few questions that come to mind that would inform my design.

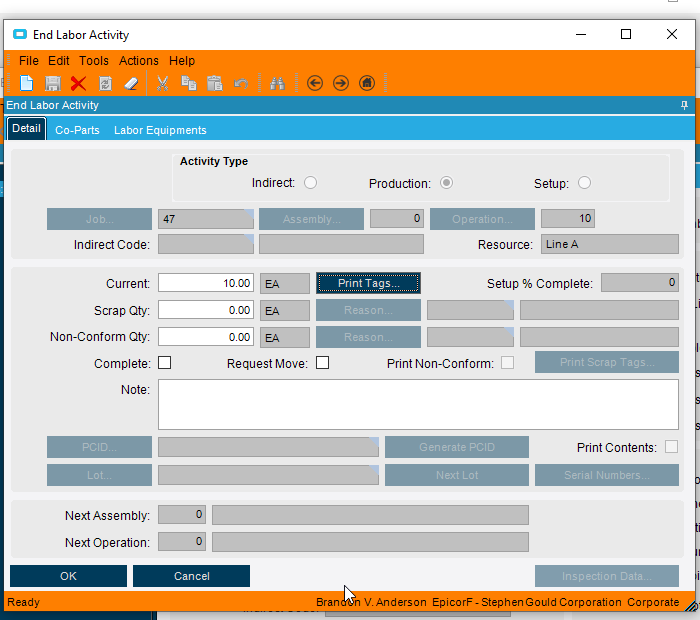

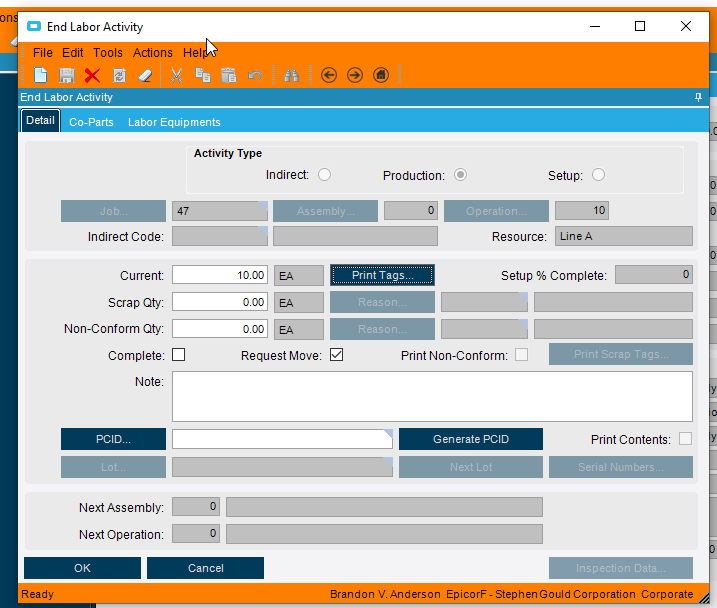

See image below. The whole bottom half is unavailable

Hi Henry

It is just a control between operations. Again I really thing the PCID function would answer the mail but nobody seems to know much about it within the MES/WIP side.

Thanks

Dave

Brandon

We are able to get the PCID to light up and be available but for some reason only on the actual last operation. we use operations 10, 20, 30, 40, 90 and 100. We flag operation 40 as the ‘final operation’ but the PCID still only becomes available on operation 100.

Well, that sounds like a bug then. I haven’t messed with that check box and getting it to work.

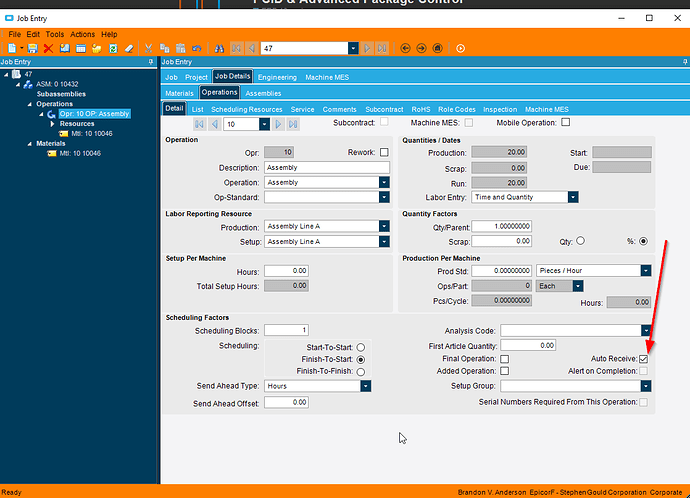

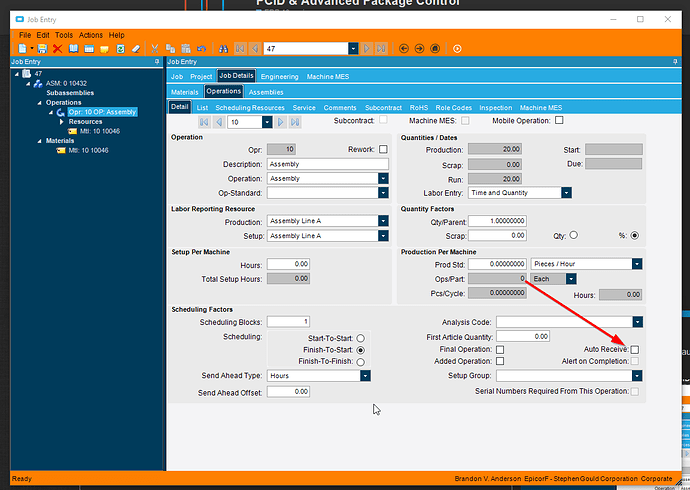

I just noticed this. Do you happen to have auto receive turned on in the operation? This seems to make the PCID part of this unavailable.

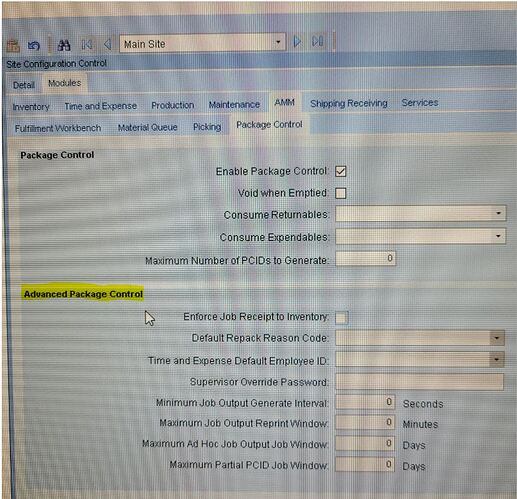

The “Advanced Package Control” is a “future” release. I have not seen any update on anything related to new PCID functionality in any recent document. There are a number of tickets with development to fix current PCID functionality but nothing new (others do have better access to this info than me but nothing has shown up and any released product roadmap documentation).

As it relates to Lot in a job, you CAN create a Lot number for a part before you actually use it (Via Lot Maintenenance screen) then you can use this info to create labels however Epicor will not directly track this until the product leaves WIP.

It was said before but in my experience there is no PCID functionality within WIP that I have seen.