Hello,

We do average costing. We have put parts into Nonconforming and the cost of the parts change dramatically. Ex. Last week we had a part in NCR and it cost $0.008. Today it is $0.0006 The only activity on that part was entering production

Another part was $.07 last week now it is $1.77

Average cost will change based on what goes into inventory and is taken out, plus any adjustments you make. What does Part Transaction History Tracker show for the part?

the one part is showing rejects and accepted inventory. The other part is just auto reciept into inventory. It is a different job than what was in NCR.

Can you share a screenshot?

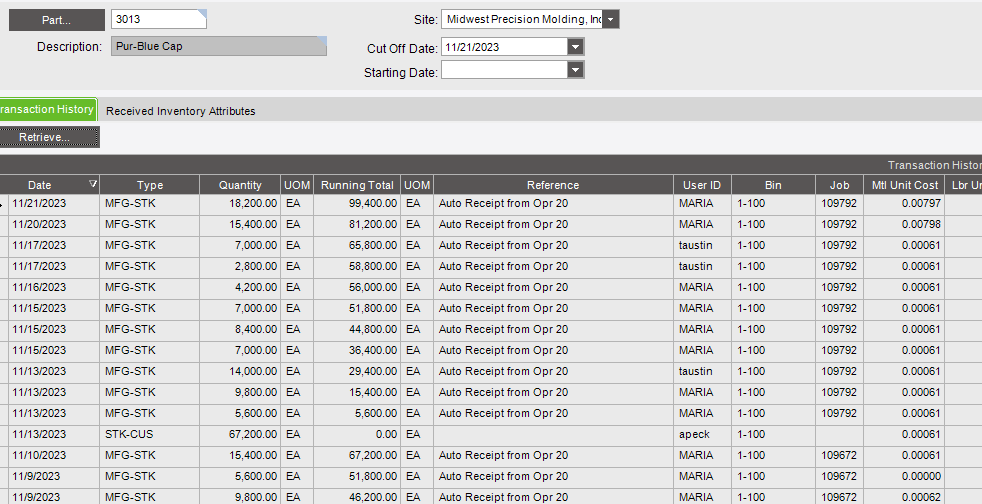

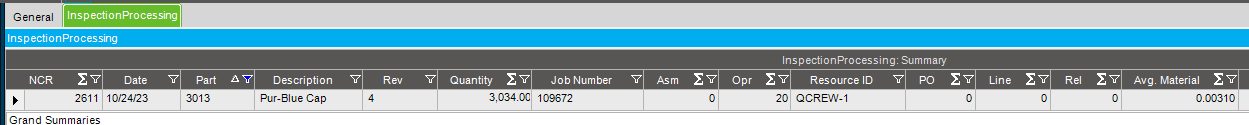

yes here is the transaction history of one part 3013 and the inspection costing dashboard last week it was $0.0006 it looks like it changed again since i made this inquiry.

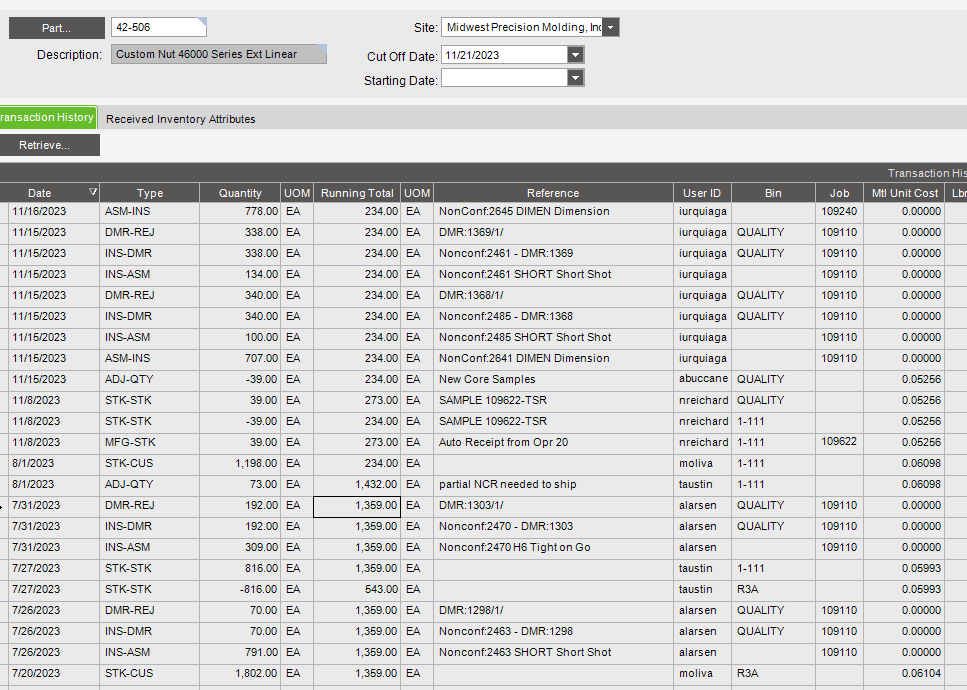

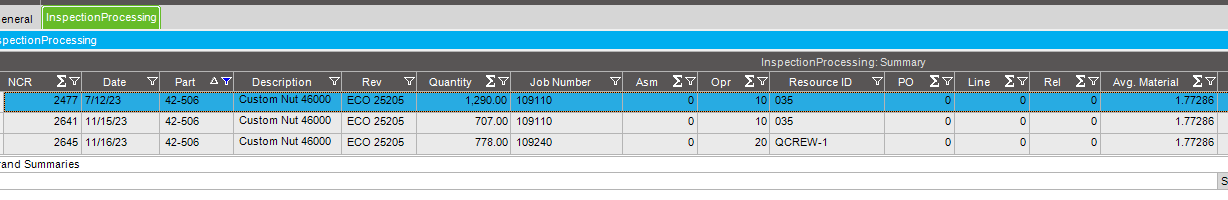

The other part is 42-506

History:

here is the inspection dashboard

Focusing first on part 3013, looking at the dates, I’d guess more material was issued to job 109792 after 11/17 and before 11/20. This would increase the per-unit Mtl cost on the job so when the auto-receipt was done on 11/20 and 11/21, it had a higher cost.

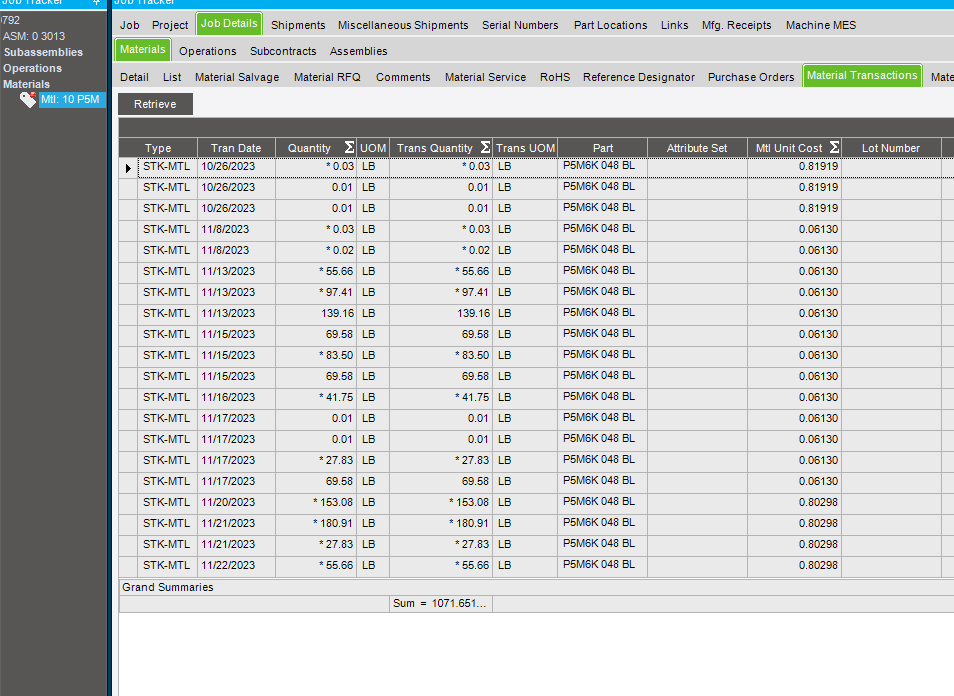

Job Tracker Material Transactions would help confirm or refute. Could you post a screenshot of that?

Also, I assume Opr 20 is the last Opr on the job - correct?

Looking at part 42-506, the NCR on 7/12 shows Mtl cost of 1.7286, which means that was calculated before that date. The Inv Tran History screenshot shows back to 7/20. Can you show what came before that date? As far back as possible, or until the Running Total was at zero.

yes 20 is final operation here is the screen shot. When you say it is higher are you saying that the material price increased when we were running it at the end of the job?

It isn’t zero until 2022 here is a video.

Presentation1.pptx (16.5 MB)

Higher, meaning if more material is issued to the job, or if material is issued that has a higher cost, it puts more dollars on the job, so when you complete parts off the job and into inventory, they will have a higher cost.

In the Material Transactions screenshot, on 11/20 there was an issue of 153.08 LB of P5M6K 048 BL at Mtl Unit Cost of 0.80298/LB. This is much higher than the prior issues at 0.06130/LB. I suggest looking at Part Transaction History Tracker for P5M6K 048 BL to find out why it was so much more expensive after 11/17. Look for a line (or lines) where it is more expensive than previously. If it is a purchased material, you’ll probably need to look at the PO for when it was a higher cost.

Thank you so much for all the awesome detail. So the P5M6 blue is a mixed material that we make. The way we have it set up is our material guys have a job to complete to mix plastic material (which we buy) with regrind plastic (we grind material(scrap runners) after jobs so we can reuse it). So it has to do with something that they are doing or how they are entering it. They did a Time and expense to add the mix material into inventory. which is done as an auto receipt from operation 10 (Material prep). On 11/20 that is when the price went up

They are definitely doing something on that material mix job (or entry) that increases the cost - it went up 13X ! Seems like maybe they missed a decimal point or used a different UOM?

Regrind can be lots of fun ![]() One of my clients has regrind too, and it took a bit of work to figure out how to manage regrind inventory, issuing regrind to jobs, how many times it can be reground before not being usable, costing, etc.

One of my clients has regrind too, and it took a bit of work to figure out how to manage regrind inventory, issuing regrind to jobs, how many times it can be reground before not being usable, costing, etc.

Oh my gosh really? We have been trying to see if there is a better way to do this. Our inventory is always messed up due to the regrind. Changing materials on jobs halfway through a run and the kicker is we have to sort our parts so we never know when to change it. I am thinking we should turn off backflush and manually issue but sometimes we put a whole gaylord to a press but won’t use the whole thing for that particular job. So not sure how to handle those. This material they are mixing is one of the higher volume ones that we barely ever stop running. I can’t see anything that he could of done. It is in LBS

Backflushing probably isn’t the right fit for this situation since quantities can vary so much. What we did was set up part numbers for the regrind materials (like 1234 for a purchased material, 1234R for the regrind version) and treat them like all the other materials. When material is reground, we used Job Salvage to Inventory to take it off the job and put in inventory. We did want to modify the costing so used a BPM at that point.

Key to success in this (and all things ERP) is what I call the first law of ERP: “Tell the system what you are actually doing, at the time you actually do it”. I’m sure my clients get tired of hearing me say this ![]() In other words, if you issue a gaylord of material to a job, issue it to the job right then. When you complete parts off a job and put them in a bin, do Job Receipt to Inventory (or auto-receive) right then. When you create new regrind on a job, Job Salvage to Inventory using the regrind part number.

In other words, if you issue a gaylord of material to a job, issue it to the job right then. When you complete parts off a job and put them in a bin, do Job Receipt to Inventory (or auto-receive) right then. When you create new regrind on a job, Job Salvage to Inventory using the regrind part number.