Use Fulfillment Workbench and handhelds. Picked by Mtrl Seq. Find a way to identify if Picking is complete for the Pack before shipping. Records are placed in MtlQue for Picking. Can’t find a way to reference the picking process from Shipping Entry to confirm all items for the pack have been picked. ie… Picked complete. Records get deleted from MtlQue after picked. Looked at PartAlloc table but don’t see a way to tie back to MtlQue. Picking can span shifts , employees, even days. Any ideas or insight ? thanks …

Have you looked at the Picked Orders functionality in the Customer Shipment Entry overflow menu?

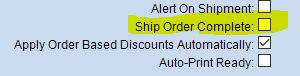

If it makes sense for your workflow, you can flag orders as Ship Order Complete

This doesn’t actually prevent anything from happening but will throw up warnings if someone tries to release only some of the lines for picking in Fulfillment Workbench, or if they try to ship a portion of the order.

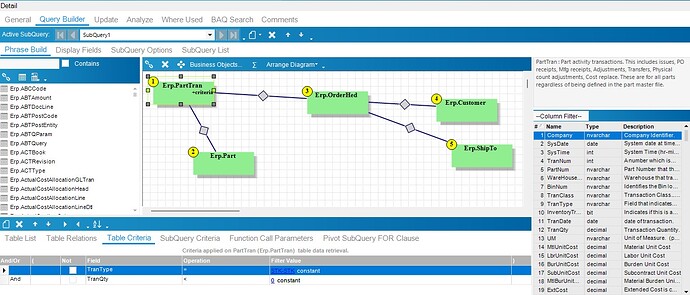

In addition to the above suggestions, you can sort of deduce a pick history despite the fact that the Material Queue record is gone.

You can piece it together via PartTran for the most part using criteria and joins to restrict the records you get. Edit: Assuming your picks are sales order based. The same idea should work with the Transfer Orders as well though.

Thanks Chad, A query based solution is the best option. Currently looking for unique identifier created during the ‘Sent to Picking’ process. The MtlQue.ReleaseForPickingSeq seems to be an option that potentialy identifies a group of records sent out to be picked together. Then once the Pack is started / created, look into PickOrders and MtlQue by above if I can carry it forward onto the PickedOrders and PackDtl. If I can’t am thinking of keeping a UD table at Picking to identify / group the records. Appreciate the ideas. Welcome any others…

This might be something worth submitting an Idea on. There are times where it would be nice to have the historical details from the Material Queue.

If you REALLY need to maintain the relationship, you could either record what you need into PartTran when the pick is written or else use a UD Table to copy the Material Queue records to as they get cleared out. In the end, we opted not to do either as the query got us close enough.

The problem with that approach is order may shipped in stages, not complete, and picked by different people on different shifts, end up in different packs. Trying to identify what was sent out for picking as a group made it all to a pack. It is tricky given the variables. thanks