We have over 1250 active manufactured parts in our system. Our company is relocating and would like to change the primary warehouse on all of those parts to the new location.

What is the best/easiest/quickest way to do this?

We have over 1250 active manufactured parts in our system. Our company is relocating and would like to change the primary warehouse on all of those parts to the new location.

What is the best/easiest/quickest way to do this?

If the old warehouse is going away, the easiest thing to do would be to keep the WarehouseCode, and just update the name, address, etc…

It will eventually go away. The current plan moved all manufactured parts to the new warehouse but there are still purchased parts (raw material) in the old warehouse. So we will have both warehouses active for about 6 months.

The “quick” one-time way would be to:

FWIW - I don’t think there is a way to delete a warehouse or make it inactive after you’ve closed it out.

Thank you. I thought DMT might be the only solution.

But before doing qty adj. Don’t you need to perform a DMT: PartWarehouse ? and alos PartBinInfo?

To associate the new warehouses/bins to the parts?

I am right into this process… and got full errors because of bad warehouse during qty adjustments…

Pierre

I once did a Warehouse move and used Epicor for all the Transactions.

As Material Handlers moved the inventory with their Handhelds, if the To Warehouse was the new warehouse then a BPM updated the Part Site Primary Warehouse (and Bin in our case).

The BPM can be conditional on Date\Time Range, Employee, Warehouse Team, etc.

This way the Primary Whse\Bin updated as parts were moved as it took a week or so to complete.

We did consider adding a UD field on the Handheld UI for ‘Update Prim Whse,’ which could have worked but we found that the other criteria worked for us since relocation was only happening on certain shifts.

Afterwards, we ran a BAQ for all Part Site’s with the old Primary Whse assigned and a Stock Status to review and make sure nothing was missing. From that List many parts were Inactivated and the rest the Primary Warehouse was updated with a small DMT update which could have been done manually, but the BAQ results were already laid out for the DMT.

Yes. I did skip a lot. Started out writing all the details, but then figured that OP knows what needs to be done in setting up.

And there’s a DMT for Inv Transfer. That would be better than Qty Adj’s

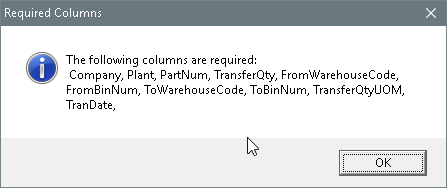

Here’s the min fields:

Sorry yep I meant Qty transfer…

Pierre

LOL - I was actually correcting my own post! You were a victim of continuing down the path I laid.

Our warehouse people have already physically moved all the part prior to contacting me to change the primary warehouse.

Did they happen to record the counts too?

But it really shouldn’t matter. If a part was physically moved, but the transfer not yet done, then any transactions would affect the QOH in the old warehouse. So that’s the number you want to use in the Inv Trans DMT.

Yes they recorded the quantities so we currently show the same parts with matching quantities in both warehouses but the primary warehouse on all the parts still shows the original location. I am often contacted after changes have been made and asked to correct them after the fact.