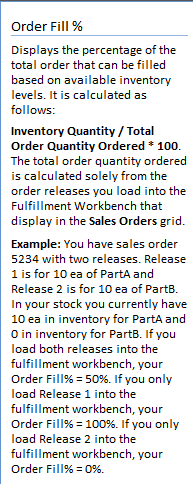

Would anyone be able to explain to me how fulfillment workbench calculates Order Fill %? From the field help:

it looks pretty straightforward, but I am finding it difficult to use a BAQ to match what the workbench shows. Currently I am taking OnHandQty / OrderQty which seems to be what this says, but there are 8 parts that are not fulfilled and I don’t see where that comes into the calculation and how to determine what has been fulfilled and what hasn’t.

That calculation is all sorts of wacky if MTO is involved is this all stock or are there direct lines here as well?

1 Like

This order is all stock. 24 lines, 2 of them have quantities left to fulfill with no available inventory.

Are you using Picking and Allocating? Can you post a screenshot of the fulfillment WB narrowed down to just that order? Click the fulfillment calc button so we can see what it derived as well. Include as many of the qty columns as you can in the screenshot. Make sure Available Fill % is one of them.

What order fill % are you deriving with your BAQ?

100%. I think the To Fulfill Qty is part of what I am missing.

e: sky is blue

If you figure out how to recreate FWB with a BAQ let me know.

The thing to keep in mind is that the calculation is done from the returned data in the grid so are there lines/quantities not represented in the grid. You said 24 lines I only count 15 in the search result. That will change the fulfill %. Below is sort of a high level overview of what all plays into that calculation.

The “OrderFulfillmentPct” column essentially represents the percentage of an order that has been fulfilled based on the available inventory and specific order requirements. Here’s how it’s generally calculated and what factors into filling its value:

1. Understanding the Basics:

- Order Requirements: Each order has specific requirements, such as the quantity of items needed, the types of items, and sometimes specific conditions like whether items need to come from certain warehouses (demand warehouses).

- Inventory Check: The system checks how much inventory is available for each item in the order. This includes checking various statuses like reserved, allocated, and picked quantities.

2. Calculating Fulfillment:

- Matching Inventory to Orders: For each item in the order, the system matches available inventory to the quantity required in the order. This might involve pulling from different batches or locations within a warehouse.

- Percentage Calculation: The fulfillment percentage for each item is calculated by dividing the quantity of the item that can be fulfilled (either already shipped, reserved, or ready to be picked) by the total quantity required.

- Overall Order Percentage: The “OrderFulfillmentPct” is then calculated as an average or a weighted average of the fulfillment percentages of all items in the order, showing how much of the total order can be or has been fulfilled.

3. User and Warehouse Settings:

- User Settings: Depending on the user settings (like UserComp.FWBUseDemandWhseOnly), the system may restrict fulfillment to items only from certain warehouses. If the setting is to use demand warehouses only, then the fulfillment percentage might only count inventory from those warehouses.

- Special Conditions: If there are special conditions like kit items, the system might have to calculate fulfillment based on the components of the kit, which can further complicate the calculation.

4. System Processes:

- Updating Records: As part of the system’s regular processing, such as when new inventory arrives or when items are shipped, the “OrderFulfillmentPct” can be recalculated to reflect the most current situation.

- Influence of Processes: Methods like

recalculatePrivate, recalcFulfillValues, and calcOrderFulfillValues are part of the backend processes that update these percentages, ensuring that they reflect real-time data as closely as possible.

Conclusion:

The “OrderFulfillmentPct” is not just a simple figure; it is the result of a complex interplay of inventory data, user settings, and order specifics so depending on your situation deriving the same value with a BAQ can range from non-event to impossible. I know it’s not a silver bullet but hopefully there is some nugget in there that will help. Take a careful look at what has been shipped/reserved/allocated.

2 Likes