Is anyone using any modules in E10 or Kinetic to log and track their gage calibrations to meet ISO 9001:2015 requirements? If yes I would appreciate some feed back and a quality contact information.

Yes, I have used the Maintenance Module and it works. Does not have all the bells and whistles of a stand alone program for it.

And standalone programs require extra work to track usage, maintain purchase history, schedule tooling if required, track assets, etc. John’s spot on, it’s very basic.

John

Any chance you can share how you set up calibrations in E10 Maintenance Module.

How do you address

1 Identification number of gage Do you use GL control number?

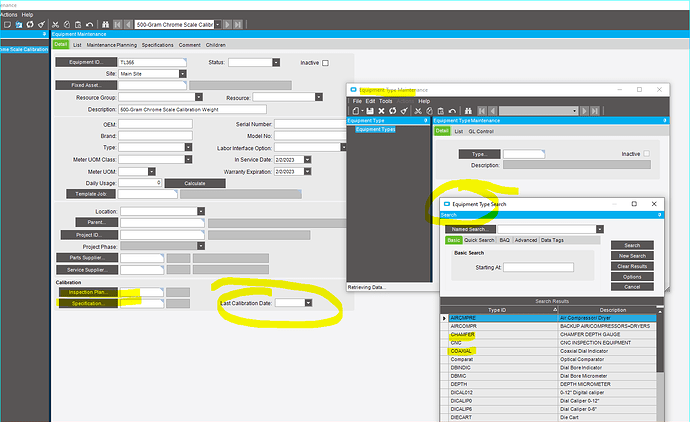

2 Do you use a standard Inspection plan for all calibrations?

3 Do you use E10 specifications for attaching to an inspection plan?

4 Reference (traceability) standards used

5 Validation certificates and calibration findings where

a. External certs where do you attached or keep them?

b. Internal

6 Details of actions taken in case of unsatisfactory results from the gage and impact on product?

Bill

I will do my best to remember, but I am no longer at that company.

If you have the Maintenance Module, this is all done through Maintenance Jobs. You create assets(?) in the module. They can also be tied to a resource so you can add them as scheduling requirements. Then each asset record can have periodicity requirements on them.

-

I think we just used the existing asset numbers that had already been assigned to them.

-

No. We already had inspection plans documented in Excel and those were imported in. We did do groupings on all of the assets, and then all like assets had the same inspection. But we were also using the module for production floor machinery too.

-

You actually do not use Inspection Plan or Specifications for this. You build a template job and assign that template to an asset and when it is up for inspection, the job is created with the steps in the job.

-

Not sure what you mean. But we had the manuals for the assets attached to the asset record in Epicor.

-

a. Attached to the asset directly in Epicor so you could just open up the asset record and see all documentation.

-

b. Same as 5. a.

-

Since it is a job, you can enter all notes and results in the Maintenance Job that is the record of the inspection.

Thanks John

I still do not understand the structure. Are the “ASSETS” grouped For outside calibrations of Coordinate measuring machines, Gage blocks, Gage pins, or thread gages we send to outside calibration labs, there is not a Resource or a machine that is assigned. So there is no scheduling of a job.