Hello all,

We have recently been receiving a high volume of new parts from customers, and our old process for handling them has become inefficient. We operate in a Make to Stock manufacturing environment, and we need a workflow that minimizes manual intervention while ensuring MRP generates the correct job suggestions.

Old Process:

- Receive PO from customers

- Enter Sales Order

- If the part is new → Stop → Email Engineers to route the part

- Engineers email back once routing and revisions are approved

- Re-enter the part on the Sales Order

Desired MRP Outcome:

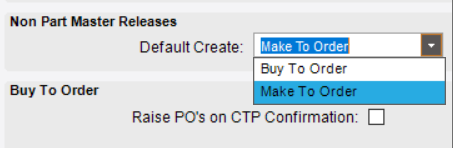

- Make Direct Flag stays off

- Unfirm job suggestions created as Make to Stock

New Process (Implemented):

- Receive PO from customers

- Enter Sales Order

- If the part is new → Enter as Part-on-the-Fly (POTF) on the Sales Order

- POTF appears on the “Engineer To-Do List” (custom dashboard)

- Engineers create the part, approve revisions

Issue:

-

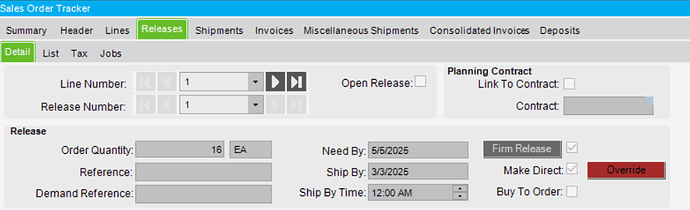

Sales Orders with POTF automatically get the Make Direct flag enabled

-

Even after the part is fully created, the flag remains and cannot be edited

-

MRP still generates Make to Order job suggestions instead of Make to Stock

I attempted to resolve this by creating a BPM to uncheck the Make Direct flag, but MRP continues to generate Make to Order job suggestions.

Question:

How should our new process be structured to allow POTF entry while ensuring MRP properly generates Make to Stock suggestions instead of Make to Order?

TL;DR:

We are transitioning from a manual, email-heavy new part creation process to an automated Part-on-the-Fly (POTF) system to improve efficiency. However, POTF parts automatically enable the Make Direct flag, preventing MRP from generating Make to Stock job suggestions. Even with a BPM to uncheck the flag, MRP still defaults to Make to Order. We need a workflow solution that allows us to enter POTF parts without triggering Make Direct behavior, ensuring MRP correctly suggests Make to Stock jobs.

Any guidance would be greatly appreciated!