Hello

We order identical raw materials (e.g. wood board) from multiple suppliers using their part number. Is it possible to receive each of these parts into a single part number so to consolidate our inventory list?

Thanks

Hello

We order identical raw materials (e.g. wood board) from multiple suppliers using their part number. Is it possible to receive each of these parts into a single part number so to consolidate our inventory list?

Thanks

Yes, make your own or pick one to stock under and then make the others supplier alternates.

Can you elaborate on the process of creating supplier alternates? Is this done under the part window?

Thanks

We also have done this and I am looking to do exactly what you’re trying to do, just haven’t had time to mess around with it nor people yelling too much about cost differences just yet. Very interested to see what @gpayne has to say.

And @abill9 if you don’t hear from him, I’m pretty sure you’ll find more info in the application user guide and/or the job costing tech ref guide (maybe), or one of the other tech ref guides. Do you know where to find those? have you ever seen those?

Id be interested to look through the guides/refs you mentioned but no, I do not know where to find them.

EpicWeb:

You’ll learn a ton from them and answer a lot of your own questions, but I must say this specific question is not spelled out super straightforward in the guides. You’ll need to work with a couple different useful functions in the system.

Like you could make one part and then just add that part to supplier price lists for other suppliers that can supply that part and use supplier part cross reference to maintain the fact that each supplier might call it something different.

But if they truly are different parts being supplied from each supplier and therefore should be set up as as a different part in part maintenance, then you can do that and add those parts as alternates to your main part. That’s also covered in the guides.

I’m not 100% certain about either of those statements as I skimmed through what I could find in all the guides and tech ref guides immediately available for kinetic on that page, but I think this is how it would be used.

At the very least the guides get you going and you can try out whatever you learn in a testing environment to confirm what you read/understood was accurate.

Found the guides; thanks for the help there as well as the solution suggestions. I will look through these and see where I get. Maybe someone will reply here and share their own solution with us. Cheers

We have an in house part number that is supplied by four different vendors.

Demand shows for the inhouse part and the default supplier normally gets the PO, but the buyer can source from one of the other suppliers and it is received and stocked into the inhouse part.

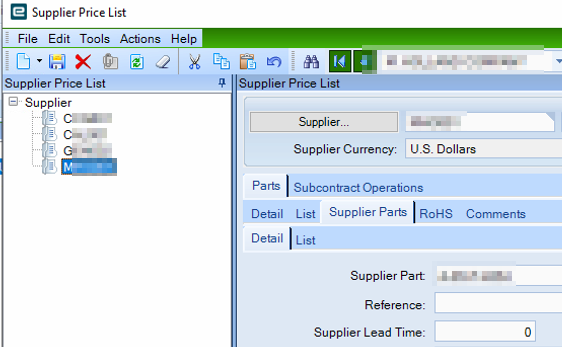

Supplier Price List has the functionality of creating Supplier Cross-Reference part numbers (as shown in @gpayne’s post).

Set the Effective Date to today (or earlier in the past), and you can leave the Expiration Date blank or enter an ending date if you want to add in pricing too. This functionality has short paragraph and a screenshot on page 53 of the Purchasing User Guide for 2023.2.

Thanks Ernie!