Sorry, it might be a bit of a long one. I am still trying to work out why the unit price works out differently if we book out 1 part or multiple parts. I have an open ticket with Epicor and Development have advised it is the Pull As Assy setting but I am still waiting to find out if they will confirm how this setting affects the calculation as it didn’t seem to make a difference when I changed it in the BOM.

The BOM is structured with some raw materials and 3 phantom parts. Out of the 3 phantom parts one has a part with a manufactured BOM + 3 raw materials. All of the materials in the BOM and the phantom itself use the same UOM (KG). The manufactured part and one of the raw materials is consistently calculating a higher issued quantity in the JobMtl table than is shown in the RequiredQty.

All our parts are set to Backflush and although we currently use Kanban Receipts I do get the same results if I create a job and book using Time & Expense Entry.

I have checked the following:

- BOM for scrap (against the Operation and Material)

- Part setup for UOM, Plant and Planning fields

I really don’t know where else to check to understand where this calculation is coming from?

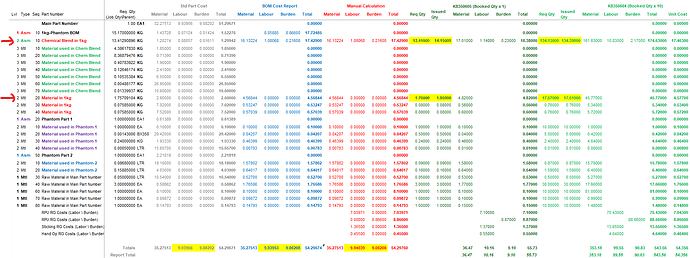

Below is a summary of the standard part costs against the BOM cost report and a manual calculation, and also data from the JobMtl table for a booking of 1 piece v 10 pieces in case it helps show the issue more clearly