We are in the process of setting up Epicor Kinetic and have run into, what we feel is, a very fundamental issue.

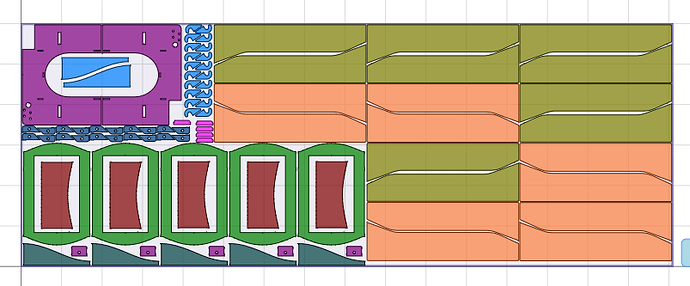

Our shop has 2 Bystronic CNC lasers and 1 CNC waterjet. Primarily, we’re dealing in sheet metal material, which we nest multiple parts onto via a dedicated Bystronic nesting software. These “nests” can have dozens of different parts on it, with multiples of each.

I’ll give an example of the issue:

Traditionally, we would sell a weldment on a sales order. This sales order is then assigned a specific job number. That weldment may consist of 200 different parts, some being different thicknesses. We nest like thicknesses together, resulting in some nests having dozens of different part numbers. The operator would record and charge their time to the singular job number, all at once. So, effectively, the charged cutting time for all 200 parts are flowing to up to a single job number (a 200:1 ratio).

In Epicor, the sales order is converted to individual job numbers for every single part/weldment (a 1:1 ratio). The issue here is that a single operator, who’s time should be spent operating the laser, would now have to sign in and out of every single one of the 200 jobs. This does two things, it wastes an extraordinary amount of time for our operator and would be essentially taking the real time to cut the whole sheet but now multiply it by 200x, blowing up costs.

In attempt to solve this, we first sought out job batching. Unfortunately, there seems to be an issue splitting the costs of the batched job back up to its individual job numbers. So, we’re left with orphaned costs not making their way accurately back to the final job; our production detail report then shows discrepancies. Additionally, we also have a sandblasting bay and powder coating booth. The laser operation is almost always OP20, however, the blasting/coating operations will always vary. Both of these operations consist of combining, or batching, multiple parts to coat all at once with like colors. A similar issue to the above laser nesting issue. The problem here is that, to my understanding, all batched jobs must be on the same operation code. That may work for laser, but not our other operations.

Another attempt was to create a mock part that essentially represents the full nest for that given material thickness. The operator would sign into this job to attribute time, issue material to, and salvage material from. That being said, they would still need to sign into the other 200 jobs, though they would only be recording their completed quantity. With this, the operator’s work queue would be incredibly long, especially if there are 5 other active weldment jobs consisting of 200 parts each. In order to find these needles in the haystack, each part job would need to have a unique nest identifier that could be sorted and grouped in buckets on the queue. The issue here is that the nests get created AFTER the jobs have been released so there would be a lot of jobs to re-enter for a single line of text. It also creates the need for a separate spreadsheet to track nest numbers, which we would like to avoid.

These are our ideals:

- Limit the amount of time an operator must spend entering information on the floor.

- Accurately capture time. Not so concerned about capturing every individual part’s time, but it must be true at the very top-level job.

- Still retain the visibility and ease of tracking individual parts/jobs.

I wish that there was a simple, singular window that allowed the master job to track time and material and that would contain all sub-components and could easily enter quantities for all.

Like I said earlier, this is a fundamental issue for our company. I also feel that we cannot be the only company using Epicor that deals with CNC equipment where multiple parts may be processed at the same time. If anyone has any experience with this resolving this type of issue, please reach out.

Thank you!