That sounds promising.

Today I tested on preprocessing of the auto receive operation

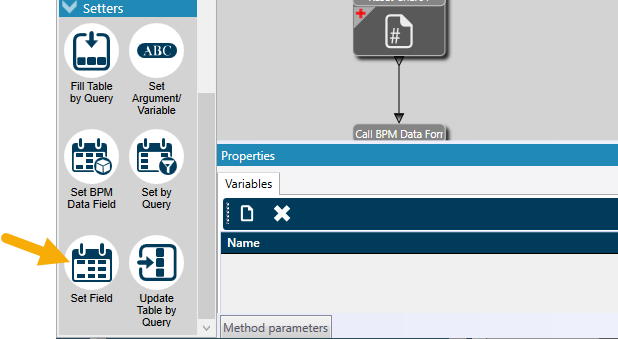

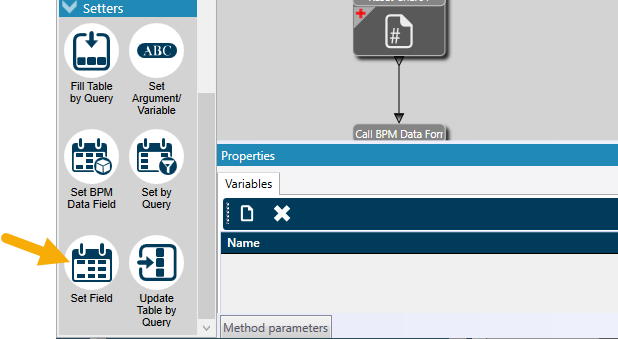

What business object / method directive did you use to do that? Was it C# code that did it or did you use the built-in set field thingy?

That sounds promising.

Today I tested on preprocessing of the auto receive operation

What business object / method directive did you use to do that? Was it C# code that did it or did you use the built-in set field thingy?