We are attempting to use finite scheduling for our resource groups and are running into issues of the system telling us that we can start jobs today even though we do not have the components on hand to issue to the job. We have turned on Constrained Material for all of the purchased parts as well as all sub-assemblies. We have reschedule in and out deltas of 7 on the parts. We run the process in the following order: Process MRP, Planning Workbench Job Process, Calculate Global Scheduling Order, Global Scheduling, Production Planner Process. Does anyone have an insight as to why Epicor is not scheduling based on the constrained materials? Is there a cheat sheet on how to make this work and what order processes need to be run in? Thanks in advance.

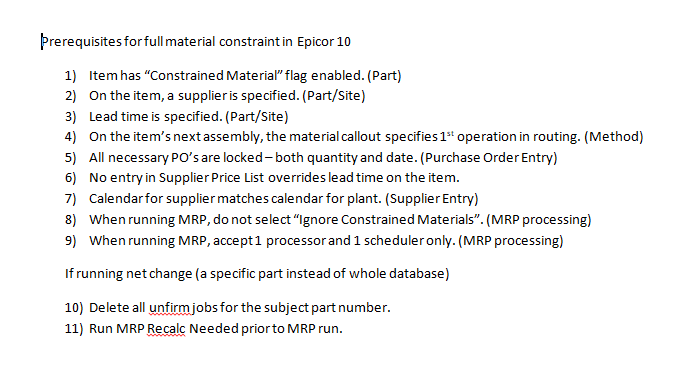

I’ve published this before, in order to constrain on material, the following steps have to be taken.

I have not edited this list to test what items might be removable, but I do know that if you follow these steps, material constraint will work. Did it myself last night.

Hello Gil,

We are having some problems with MRP and constrained materials. Specifically when it comes to Manufactured Parts. My team and I are curious if you knew whether or not this works only for Purchased Parts or also Manufactured Parts? You mentioned in the Prerequisites on this reply that you would need to have a supplier on the part, but that wouldn’t apply to our manufactured parts issue we’re trying to figure out. We’re curious if you have any insights into our issue. Any help is appreciated, thank you.

In Part entry select Constrained Material if it is Manufactured also you could use manufacturing lead time calculation to provide the cumulative time and or add a modifier if manual is checked.