We have always built finished parts to stock that enter FG, where the Job # traceability stops. For example, on our Epicor Sales Order Shipment Status with blank Job # column. We don’t build to order because you have to ship that Job to PO xxxxx which would restrict us in various ways. Another example, test fallout may sit on the shelf and ship months later on a different P.O. Do you know a way to get the best of both worlds, where we build to Finished Goods, ship to whatever P.O. we want, and automatically retain Job # traceability?

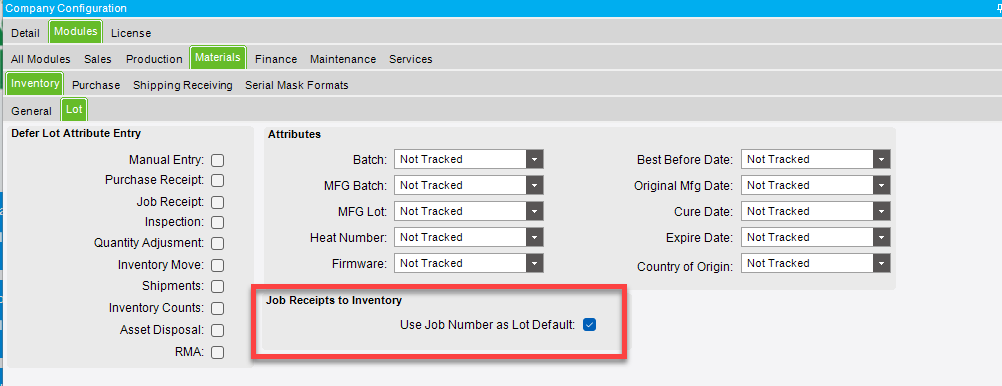

I would assume Lot Tracking the FG part would provide that.

All we run is make to stock.

We have all our jobs named Order-Line-Release. That is our link.

True stock jobs (not made for an order) are just next number.

And…