Morning All,

Im on a new tangent today Maintenance Jobs

Im trying to put in a daily 1hr maintenance check on a machine, in testing, to see if i can get the plans to generate out to the same horizon as the schedules

Im using things below in the method below, so id appreciate an opinion on what i am doing that maybe incorrect, Im trying to in essence make sure the schedules are blocked out so we can get the TPM done, againts our plans, and handle breakdowns as the abornmality.

Equipment - Ive created my equipment, and linked to the resource.

Meter UOM - Ive created a class for “days” and ive set my daily usage as 1

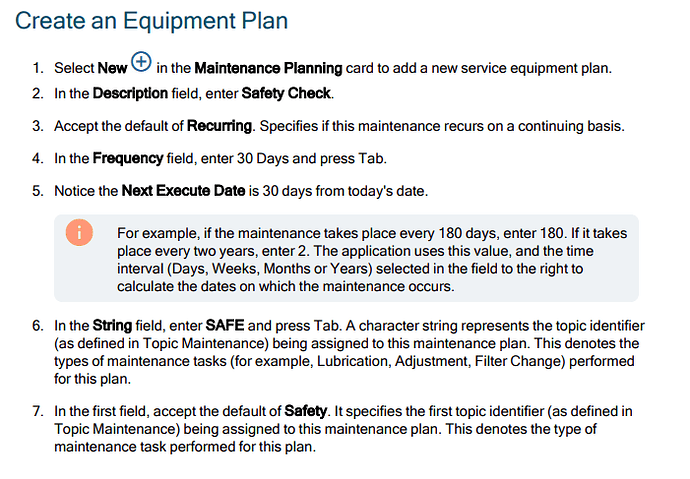

Maintenance Planning:

Created Plan,

Frequency 1,

Time UOM = Days,

Next Execute Date = Today

Buffer Days = 30 (my understanding here is next 30 days of requirements to be considered?

Template Job = I have 1 job in 1 operation, 1 hour, as per normal stuff

Recurring = True (my understanding is then 1 plan line can repeat itself)

Processing The Plan

Run Update Recycle thresholds for MRP jobs

Run Maintenance Plan Process

Run MRP in Net Change with cut off in 30 days

I get 1 Maintenance job, not the 20 or so, for the months daily checks.

Im getting alot of bugs in Pilot on our demo account, wondered if the way i set it up was at fault or the environment, getting errors when entering meter readings so presumed id speak to the community before even trying explain myself to Epicare.

Any guidance on how people have set this up or are using it would be handy, I want as the scheduller to consider the mainteneance and checks so that we can make sure there is an accurate plan to work to, and the maintenance team as limited in resource as it is can be utilised across the plant. nothing worse as a scheduler than failing machinery, TPM TPM TPM!

Thanks

Mitch