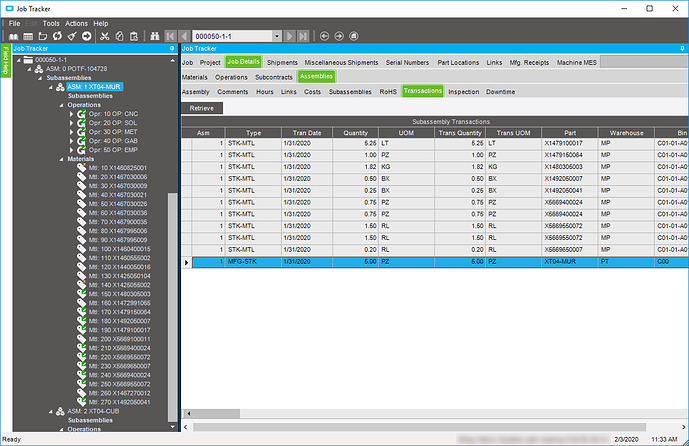

I have a user trying to issue an assembly back to a job. They receive the assemblies to stock when done and issue them back when ready to assemble the parent.

This one, however, is giving an error I haven’t seen before and have been fruitless in diagnosing; “Material change does not respect existing allocations”.

I’ve ran a few BAQs (PartAlloc, PartWIP, WhseBin) and looked in various trackers (Job Tracker, Lot Tracker, Part Tracker) and the allocation column has always been zero.

I cannot figure out where to look.

Has anyone seen this?

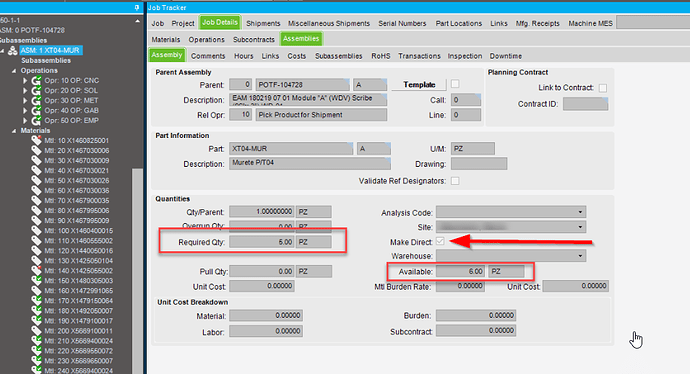

Is it normal to have a Reqr’d Qty of Zero?

Hmmm, it would seem not.

They were able to issue assembly 2 without problems, but 1 and 3 share the same issue and they both have a required quantity of zero, but asm 2 (already issued, mind you) has a req qty of 5.

May be a red herring. Not sure why the one already issued would show a requirement.

Should be 5 for asm 1 too:

We don’t use that functionality, so I don’t now if Required Qty, means total required (regardless of prior isses), or remaining qty required.

Also, does Asy 1 and Asy 3 have the Issued Complete already checked when you first load those records?

Both are unchecked when loading.

I assume it’s the total quantity required regardless of previously issued:

From the Field Help:

Required Quantity

Displays the required quantity for the job assembly sequence.

It doesn’t look like all the Material for Assy1 was issued. Yet you said it was received into stock?

And is Asy2 the same “Pull as” value as 1 & 3?

Yeah–from what they tell me they don’t always use all of the material that the BOM calls out. (Don’t get me started). It was, indeed, received to stock, however.

This is interesting. Asm 2 has a pull quantity of 5, but Asm 1 and Asm 3 have a pull quantity of 0.

However, judging by the routing, it appears that all 3 assemblies are made on the job, so having a pull quantity on Asm 2 doesn’t initially make sense to me. Is this a necessary thing to mark since they’re going to receive it to stock and re-issue it?

*Edited because I forgot pretty much half a sentence. ![]()

Another thing standouts on the screenshot of the job tracker, “Make Direct”

We don’t use sub-Assy’s this way, so I can’t tell you how it should be. Just thought I’d give my 2 cents on what might be different.

Asm 1 is the only one marked as “Make Direct”, but shares the same error as Asm 3 which has that unmarked.

The “Pull Quantity” has a consistencies between the two that don’t work and the one that does, so that seems like a great place to start.

I have found a few postings that point to the error being related to reserved quantities. I haven’t worked with reserved quantities yet, only allocations. They seem very similar to me:

@hmwillett - have you run the rebuild process that recalculates the Allocations?

I have. It did not affect the job in question.

Maybe I’m not doing it for the correct part, but the assembly part XT04-MUR has zeroes across the board.

I could not find a field called ReservedQty in the JobHead table, either.

The red dot material seems suspect, however.

What does the red dot mean in Job Entry?

What screen is used to reserve material? I don’t see “Order Allocations” in the menu.

From the help:

Indicates that, today, there is not enough stock available to satisfy job’s material requirement.

Example: You currently carry 20 units of ’ Part A ’ in stock, but require 100 pieces to satisfy the job. If you schedule the job, the red dot displays, indicating that there is not enough on-hand quantity available to cover the material requirement. Now, if you enter a purchase order for 80 pieces and reschedule the job, the red dot will still display. For the red dot to clear, you must receive the purchase order and reschedule the job .

That might be why Asy1 & 3 behave the same, while being different.