I am too,

I’ve still got a long way to go to learn Epicor, I have more of a networking background so everything ERP related is new.

I am too,

I’ve still got a long way to go to learn Epicor, I have more of a networking background so everything ERP related is new.

That’s correct.

It’s not a bandwagon… it’s a train.

Coming your way.

It’s the oncoming light in the tunnel…

I’m hoping Epicor adds the HttpResponseMessage object to a widget so we can make REST calls without code.

Just a suggestion (cough, cough) @Bart_Elia…

Mark W.

why would you need a rest call from within epicor? (or maybe that’s a joke?)

Oh, no joke my friend. This is how much of SharePoint online users do customizations. Instead of attaching to adapters/business objects/etc, they just call SharePoint via REST and get what they need. Need a list of serial numbers but you’re already using the dataset for serial numbers? No problem!

And integration into other systems is a breeze:

Want to send an email via O365 and not worry about SMTP setup? Bam.

Want to know the expenses from Concur for your project? Snap.

Want to print labels to any printer you damn wish??? And reprint them? Swoosh!

Add a task to (insert task management program here)? Check!

Want to make Batman sounds in a techforum? Gazzboom!

(sorry, got excited there)

AND this is a loosely-coupled modification! No DLLs to bind or maintain! Upgrades are waaaaay easier!

So yes, no joke. Which is odd coming from me I must admit…

Mark W.

But @Chris_Conn, people wouldn’t think you were dead…only RESTing.

and there it is…

Thanks for the response all, I’ll look into the BPM but after some of the information, it may be better to just leave that there.

I’m going through some example jobs and seeing what happens with each transaction, and (of course) I have another question.

I’ve started my job and issue’d the material to my job, and when I do the Report Qty, it puts the Assembly in WIP, but it only relieves a single child material instead of all 3. I have the “Auto Receive” not checked, and they all look similar in the BOM.

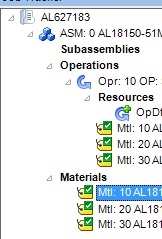

Here is a screenshot as an example:

Job tracker:

Portion of the BOM:

I feel like it’s something small I’m overlooking, but I compared the one that is removing quantity to the other two and did not see a difference.

Also, if I don’t return the material and or do job receipts to inventory, it looks like if I close the job that material just vanishes (?)

That just allows extra from make to order jobs to go into inventory.

Like Chris said, this is more of a holding bucket. We don’t use it because it’s confusing. Just clock into the op and clock out with a quantity. It works much better.

Yup. If you don’t do something with it, it just gets rid of it. You need to receive to inventory or ship it, depending on your demand link. If you really had a job that you were just abandoning, you wouldn’t want to to automatically do something with it.

If I’m understanding correctly, for the report to correctly calculate the labor I need to use the Report Qty?

@Ernie , am I understanding the process correctly for correctly obtaining labor for reporting?

Clock Into Job

Issue Material

Report Quantity

Job Receipt To Inventory (This is because we lot track containers, so these two processes will happen several times during the shift)

Return any unused material (I haven’t tested this just yet.)

End Activity

So in a job where we run 300 pieces, if each container has 30 pieces, we would report a quantity of 30, then do a job receipt to inventory and print that label with the lot number. This would need to happen 10 different times before the job was complete.

I hope that makes sense, I’m still trying to grasp the best way to achieve what my company wants to achieve.

For the issue of it only relieving one of the material pieces instead of all 3, what might I need to double check?

when you clock out of a job (end activity) you can put your quantity in there. The report quantity is the odd holding bucket that basically just puts the number in when you end activity. You don’t need to use it at all. You’re probably best off to just start activity, stop with the quantity you finish, then start again. It’s extra steps, but if you need to receive to inventory to do your lots, you want the quantity actually completed, not in that holding bucket.

Correct, but as mentioned above, if the operator reports the quantity AFTER the job receipt to inventory, the labor costs will go to variance, and not to inventory.

That is a concern, is it not?

(Assuming we’re looking to track the labor associated with these jobs)

So the work flow, to get everything accurate, would look like this:

Clock Into Job

Issue Material

Return any unused material (I haven’t tested this just yet.)

end activity

Job Receipt To Inventory (This is because we lot track containers, so these two processes will happen several times during the shift)

start activity (clock into job)

Issue Material

Return any unused material (I haven’t tested this just yet.)

end activity

Job Receipt To Inventory (This is because we lot track containers, so these two processes will happen several times during the shift)

Lather rinse, repeat…

It’s a pain in the butt, and I would look at trying to automate as many steps as you can, but whenever you do a job receipt to inventory, the hours and material costs that are on the job at that time will get attached to that transaction. So if you issue all of your material first, then piece meal receive to inventory, it’s going to be messy.

You are probably better off making more jobs that have the correct lot size so that each job is one lot. IMHO.

Epicor will track the time between Clock In and Clock Out and base the labor and burden values on that time. Report Quantity and End Activity are two parts of the same process, so they happen simultaneously. Return Unused Material should happen BEFORE Job Receipt to Inventory so its cost doesn’t get added to the value of the finished goods.

Yes, if your job of 300 pieces will be received into 10 lots, there will be 10 Job Receipt to Inventory transactions (one lot per transaction).

There’s an awful lot to grasp… feel free to ask anything.

This is hard everywhere. Don’t feel discouraged!

Definitely not discouraged! Just trying to figure out the best way to get this done, and attempt to keep it relatively simply for our associates.

So to accurately track pieces for inventory, let’s say I have a Job for 300 pieces.

The correct process would be:

Start Job

Issue 30 pieces of each material

Report Quantity

Job Receipt (Shouldn’t have to return any material if they only received in enough for the container)

Repeat above step 10 times (for all 300 pieces)

End Activity

So that way they’re only issuing the correct quantity of pieces for the next container to the job?

No. Report quantity doesn’t actually complete them. Only end activity. (told you it was confusing) Instead of report quantity, you need to end activity (with a quantity) then start activity again.

If you don’t do this, your costs will be jacked up. (maybe that’s acceptable to you?? I don’t know)