But the Report Qty is needed to not throw the error mentioned above for having a completed quantity of less than the Job Receipt to Inventory?

not if you end activity. That completes the quantity. Don’t just leave a 0 in the quantity.

Start activity creates a labor detail row. You can see that in T&E. report quantity just adds to the completed quantity on that row, so that when you go to end quantity there is a number in there. I doesn’t actually do anything else (including bring over cost). Then when you end activity, it completes that row. If you aren’t receiving to inventory until after you are done, that’s not a problem. But if you have to receive to inventory as the job is being completed, you should complete the labor detail row (end activity) If you need to do that in lot sizes, you really should have a labor detail row for each lot size.

Let me ask you this, in your business, can you complete all 300 before you need to receive them to inventory? Because if you can, you can do this.

start activity,

issue material

return material not used

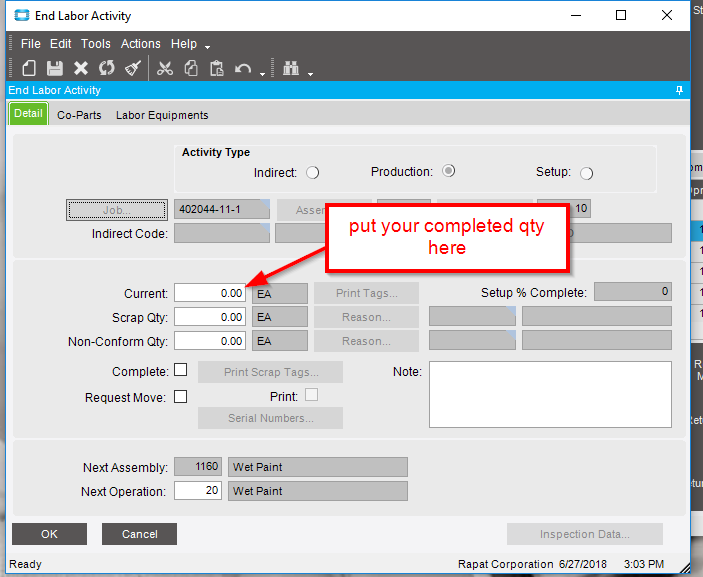

end activity (full qty)

receive from job to inventory qty 30, repeat this line 10 times (or automate it so you can do all 10 receipts at once)

Would that work? I don’t know your business so I don’t know if it can.

Well the problem really comes with the lot tracking aspect, so once we fill a container, they need to produce a lot number and put it into inventory for the next process.

These machines are capable of 1920 in 8 hours, and each container can hold 200 or so if I remember correctly.

Unless there is a better way of tracing parts and where each container went to. (This is because if we use job lot numbers, these jobs may be for larger quantities and the job may take several days to complete instead of a shift.)

I guess that goes back to smaller jobs that match the lot size.

I missed 24hr, and this thread has gone wild. I was only reading on my mobile yesterday, so couldn’t share what I wanted to. I’m on my laptop now, so here goes:

My requirement is similar to yours, in that we might be making quantities that are greater than 1 pallet - see SCC002KB for instance. We break down the job into pallet size, as we’ve always used the 5 digit job number as the last 5 digits on the Lot Number. Our Lot Number is in the format of PARTNUM.EXPIRYDATE(DD-MMM-YY).JOBNO, so I couldn’t use the “Next Lot” button as the format was too complicated for the sequence generator.

What the code behind the process button is doing:

Employee Clock In

Report Quantity

Create Lot

Job Receipt To Inventory

Job Complete/Closing

Employee Clock Out

I then expanded the solution to allow for Issue of Materials - I’ve mirrored what the Kanban Receipts screen does for Lot tracked materials:

You select a line in the “Lot Tracked BOM Items” in the top half of the screen. Then, it will show available lots (this is filtered to only the departmental warehouse not all stock). User can highlight the Lot Number to issue from, and then issue.

I think I’m pushing @Chris_Conn achievements with the number of lines of code…

I’ve invested many many hours into initial development and continuous improvement on this one - so I’m not willing to share it in it’s entirety but willing to explain any of the moving parts. It’s because of the great people here that I’ve managed to get this done - having a proper project to work on and challenge me helped massively. BLTester is also good to help test.

+1 for heavy coding

It’s actually slightly longer than I originally revealed… I was embarrased to include the last method in the line count…

That’s seriously impressive.

This is done outside of the MES, and your shop floor associates use it?

How do you handle the labor aspect? With them processing and everything in a single button, isn’t there virtually no labor cost reported?

Yes used by production operatives - we are backflushing labour and some materials, so no need to report time. But the principle would be the same, you can have a field or 2 to collect the info that you need from the user and then mimic what the Time and Expense Entry screen does by tracing putting a manual entry through and then getting the adapter to do the same.

I’ve not customised MES much, in theory everything on my dashboard customisation could be done in MES because the adapters that I’m using are all available to MES.