Hi Tracy, I understand what you are saying, but we cant use Pull as Assembly, we are being told we cannot move the WIP how we “Want” inside the factory, or release jobs how we want using lots and multiples to drive the job quantities.

Please check the part parameters of part A010406061.

There is a cumulative lead time of 88 days on the C part. This A part is a constraint material for C and it has a very long lead time and when you don’t have any stock C jobs are going to be planned to start in September like you wrote in your first message

Fair enough. We have each part as an inventory part and move that way so for example if we book to the Finished Goods part and it uses a sub-assembly then we consume the sub-assembly from it’s On Hand quantity.

If you have a consultant helping you with all these fields then I am sure you will get there ![]()

Do you have Advanced Material Management? If you do, that allows you to put WIP in Bins.

So we cut things, then bend them, then nibble them

all in different quantities, and each part has different “characteristics” so we would like to see that we have 1000 cut items, then 500 bent items, and 10 nibbled,

can that be done with the AMM?

Updated:

MRP Has Run, its not changed my demand on the V code

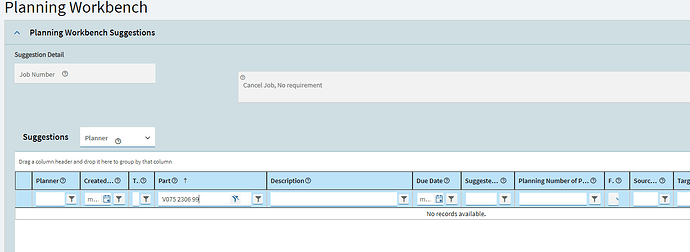

No new job suggestions in the JSM screen

Time Phase:

Its created an unfirm suggestion on the C code

Time Phase:

Its suggesting that on the 18/09 to make the material part, for the V part thats got demands on the 21/06

No planning workbench suggestions showing for either of the parts also

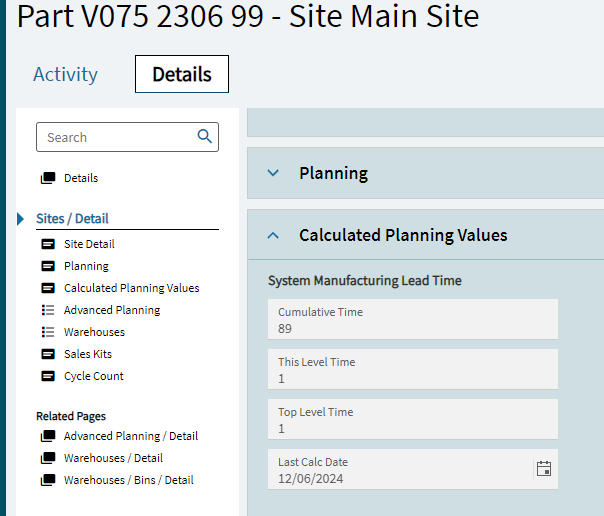

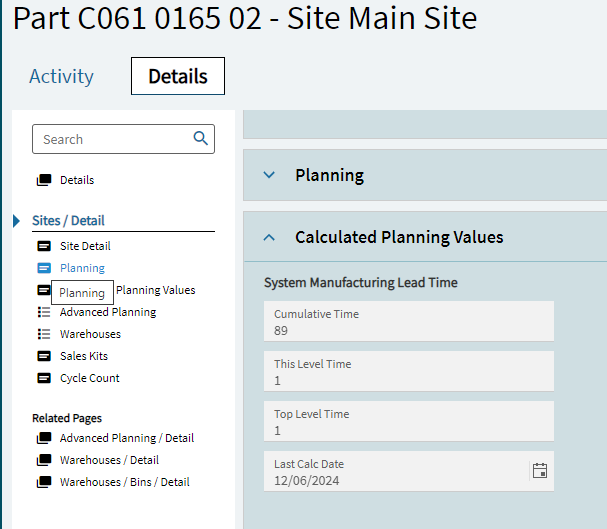

V part is considered to start with a cumulative lead time of 11. C part with a cumulative lead time of 88. Probably because of the batch size of part C you’re demand voor A is too big to be able to start directly and have it done in 3 days (this level time), so it needs A going to 88 days.

Right so that lead time calc has to be run “daily” in essence to get the right perameters in based on whatever the stock holding, lead times etc. are on the materials beneath is as constrained

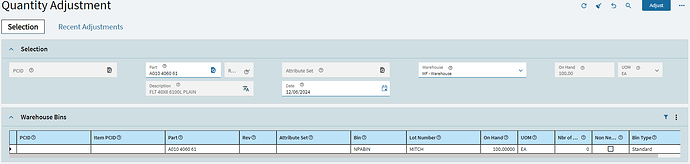

ive just uploaded some stock in our Pilot for the item,

Can you confim then if we need to run calc mfg lead time daily to support mrp running in the correct way?

We do it daily as it also calculates with the availability of material and assemblies for the given batch size. It’s also very important if you want to use Capable to Promise (CTP) in the future. If you would have enough stock A the cumulative lead time after the calculation process should come down.

Not 100% sure, but I thought if you check this option on part V the cumulative lead time is not 11 but the longest of the required parts (about 88 days)

good one to test in your pilot environment ![]()

ive run it again, and getting 88 days now on the V

and on the C

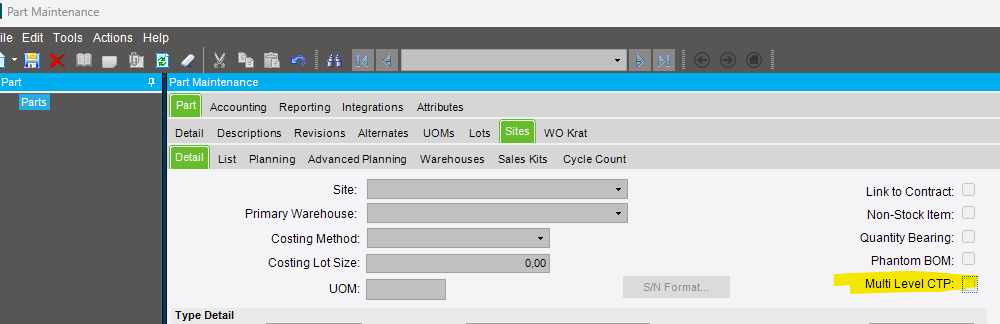

Both have multilevel CTP marked true

Now i’m very interested what MRP will do with the V job.

running it now on net change see what it suggests, any particular screen you want to see?

Not really, just wondering if you will get postpone suggestions for the firm V job

Do you use a ‘Planning Time Fence’, ‘Reschedule Out Delta’ or ‘Reschedule In Delta’ on Part Maintenance or Part Class? These parameters might prevent suggestions to postpone or expedite.

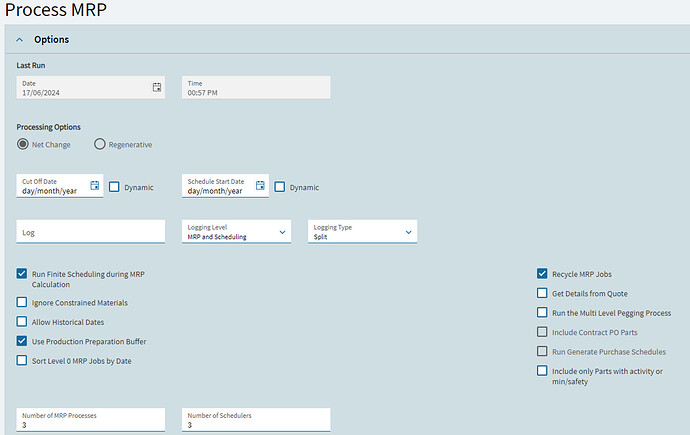

Another thing you can try is to run MRP with the checkbox ‘Sort Level 0 MRP Jobs by Date’. Not sure what it does to already firmed orders, but you can always try off course.

Morning,

yeah we are using a 7 day planning time fence, 1 day reschedule in, 0 day reschedule out, same on all parts as we want to not interfear much in the immediate week

if someone knows more on the sort level 0 by date field it may help us ticking this box

Then I think that’s the reason why you don’t get a postpone suggestions. You already run the schedule with a start day next week + the planning time fence. You probably have the same with the jobs that need V. Did you start already with the Job for V? If not, I would delete the firm job and let Epicor decide with MRP where to plan job V. Once firmed MRP only creates suggestions. It might only work if you use Global Scheduling → process that does re-plan firmed jobs.

Hi All, So ive been playing, ive deleted the jobs and started again

Ive put MPS demand in at the top level, its generating the jobs still in a funny sequence

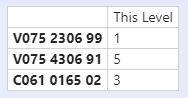

| Days (Start Date) | Days (Due Date) | Part | Sum of Prod. Qty | Level |

|---|---|---|---|---|

| 21-Jun | 24-Jun | V075 2306 99 | 3400 | Sub |

| 24-Jun | 24-Jun | V075 4306 91 | 804 | Top |

| 15-Jul | 24-Jul | C061 0165 02 | 4200 | Component |

| 22-Jul | 22-Jul | V075 4306 91 | 708 | Top |

| 20-Aug | 20-Aug | V075 4306 91 | 708 | Top |

Components go into subs, sub to top, as you can see its out, ive put in manual lead times:

Ive put in stock any purcahsed items just so that its easier to play with

Ive run MRP regen, and then net change once the MPS demand went in, and it run on these settings: note no dates to get maximum demand in

I run recycle thresholds before running, and MRP recalc after.

Question:

Global Scheduling - would you suggest i run this? I dont get what it can do based on me not having and scheduling priority codes in, also how do you “auto assign” priority codes without going into every job manually? can you get a BPM to look at as the material code in the part master to trigger “priority”? i presumed MRP would do this “deepest job in the BoM structure, build up from there” but clearly it aint

if any other suggestions id appreciate it

Thanks all

Apologies on the late reply I have to have a day off it head was mashed ![]() LOL

LOL

Running MRP without Global Scheduling will get you the results you got. Global Scheduling is what looks at the interdependencies of the jobs and schedules them to finish in the correct order. You should not need to assign priority codes to every job as you set a default priority in the system. You should only have to change jobs that you want to rush. There are ways to determine priority off of Customers, and there might be more places but can’t think of any more off the top of my head. The priority will be set by Calculate Global Scheduling Order based off of date.