We have a regular occurrence of jobs being closed off flushing out variances caused from our DMR process.

This happens 100% of the time when the following 2 are present:

-

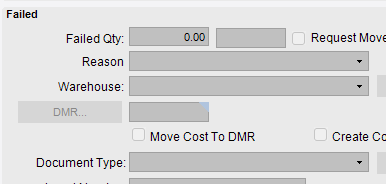

a job has parts issued to DMR and then be rejected

-

same job still has parts going through which are later booked to stock and subsequently sold

Every time the value of the remaining parts booked to stock is reduced by the value of the parts DMR/Rejected.

I have raised this with Epicare but they have been unable to assist without us putting together a demonstration of our transactions form start to end to demonstrate this. As this is not easy due to the number of people required to fulfill this request I have looked into it in as much detail as following and discovered the following:

Reviewing EPICOR transactions with my limited knowledge I can see that whilst parts are being processed through the GL from Inspection to DMR (INS-SMR then DMR-REJ) there is no prior GL transaction taking the value from stock to Inspection. Does anyone know if this is likely to be the cause of this?