We’re a manufacturer that has recently documented time studies for our production areas. The Production Standard we’ve recorded that is most universal across our production processes is a standard of Minutes per Square Foot or Minutes per Lineal Inch. For example, we might have a process of dimensioning that is 0.0287 minutes per square inch. Then we multiple the 0.0287 against our factor for each part; in this case our length and height of the part to get the total square inches cut. So if we had a part that 24"x12"x2", we’d take 24x2 to get 48 square inches and then multiple 48 by 0.0287 to get our total time for that part of 1.377 minutes. Note, sometimes this factor can change depending on the orientation of the part (so it can be length x width for some of our parts).

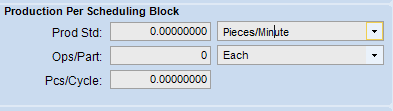

Is there a way in the Bill of Operations (BOO) DMT to record Minutes per Sq Inch or Minutes per Lineal inch to get the ProdStandard to populate correctly. I’ve thought maybe there’s a way using the StdFormat of Operations per Minute “OM” or Minutes per Piece “MP” and then maybe a combination of using other fields such as QtyParent or OpsPerPart, or QtyPerCycle.

Any ideas or solutions?

Thanks,

Tom