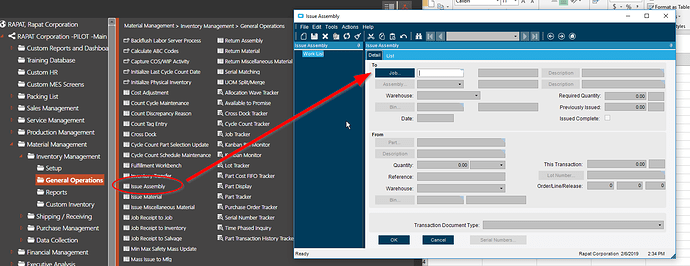

It’s issue assembly screen.

The manufactured components of the finished good can be addressed in 3 ways

- Pull As Assy - basiccly make the sub-assembly while you’re making the finished good. Only one job is required

- Create a sub-job for the sub-assy part. You’ll have a job for the finished jood which will require another job to make the sub-assy part

- Make the sub-assy part as it’s own job, with the finished subs being received into stock. Another job (unrelated to the one to make the subs) would be created, with the finished sub-assy part coming from stock.

He already has them in stock, he’s not trying to make more.

not if the job is structured as an assembly, you can’t issue material to an assembly.

At the moment he does … ![]()

and in the future he’s just going to make them on the job. He won’t need to do this. This is to use up extra crap sitting around.

So he wouldn’t use #3 from my list above, but it’s the closest of the 3 to his future needs ![]()

I guess I was assuming a little too much. I wouldn’t use pull issue assemblies for regular things. It’s more of a mechanism to handle anomalies.

If you ( @OnurCam ) are going to use this going forward, once you get to more than 50% outsource (or less than that probably), I would just change the structure on the the job/method to a material instead of an assembly and then stock them on the shelves. Then you can decide if you want to purchase or create jobs (like @ckrusen said) to satisfy demand. If it’s only every once in a while, then you can set pull quantities/ issue assemblies. If you do the material thing, your suggestions will handle the amounts you need to buy, you would just have to make sure your purchaser is in the loop so that when he gets a purchase suggestion, he knows whether to buy it, or have a job created. Also mass issue just works fine then. You just have to (should anyways) make the sub assemblies ahead of time to get the costs to flow correctly. (number 3 on @ckrusen’s list)

One more thing to think about, is if you don’t set the pull quantities, or issue the assemblies right when the top level job is built, you will have demand for the everything underneath your in stock assemblies. So you run the risk of buying extras. Issuing, or setting the pull quantity will reduce the demand for everything that goes into the assembly you are changing.

Another note on outsourcing after the job is built. The way that we (I really) do it, is to add the part number as a material and delete the assembly. I have a dashboard set up that I can feed into DMT to handle it faster. But’s it’s kind of complicated, and I don’t really trust anyone other than myself to do it. But doing it that way allows the purchaser to make PO’s directly to job. And it only works if there are no transactions (labor or material) under the assembly.

@ckrusen and @Banderson thank you both so much for all the information.

I forgot to mention that we have a big problem with planning things like purchasing parts, how many SAs we will purchase. We don’t have a dedicated person that handles jobs and probably won’t have anybody in the near future. The only thing they can(barely) do without mistakes is right clicking job number from a dashboard and then checking Released. Also they mass issue which is only 4 or 5 clicks in total.

If I were to try and show them creating jobs for SAs, and using another screen(Issue Assembly), they will say that they understand and do it a couple times. Then they will just stop and do something completely wrong that I would need to fix(if I can detect). I mean I can’t really blame people because the pay is really low and they have to handle many other things but it just makes me sad to see my baby(E10) getting filled with garbage.

So the best way would be automating everything with a BPM. But since I can’t do it, I will settle with a dashboard rule that would color the job if any subassemblies related to the part in line is in stock. And whoever is releasing the job can check all subassemlies one by one to see which SA is available(I will highlight Available txtbox). And if one day we do manage to add MES then I’ll try to find a new method. Hopefully by then people will get more experienced and comfortable with Epicor so they won’t be scared when I tell them they need to do one more thing.

I feel your pain!

Unfortunately, there is always one more thing. ![]()

and @ckrusen I enjoyed the discussion! thanks.

Thank you both so much for taking the time to explain things and try to come up with a solution. I don’t know who to mark as the correct solution you guys decide  or I’ll just pick the longest post that can help somebody else. Have a wonderful evening!

or I’ll just pick the longest post that can help somebody else. Have a wonderful evening!

I learned a lot too. We never use “assemblies” as E10 defines them. To us an assembly is the union of parts to make something new. We consider a single level BOM to be an assembly. And any component of an assembly that itself is an assembly, is considered a sub-assembly. If a sub-assy was never going to be made by itself, but was just a “container” to hold a list of parts to be used together, we refer to as a Phantom Sub-assy

So the introduction to E10’s idea of an Assembly in a MOM was good.