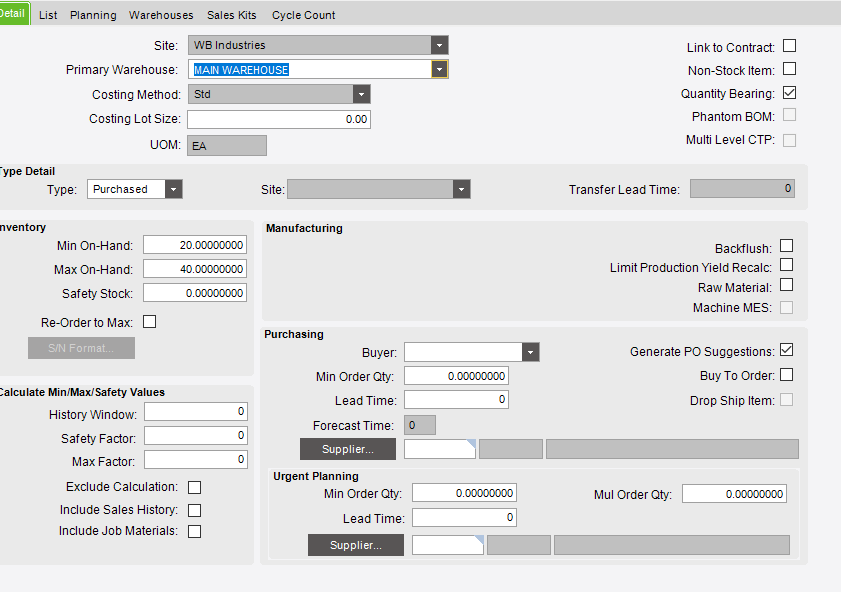

We have a part that we purchase AND make in house. The part in setup in in the Part Master as a purchased part and quantity bearing. We have a max on hand at 40 and min at 20. Generate PO Suggestions is checked.

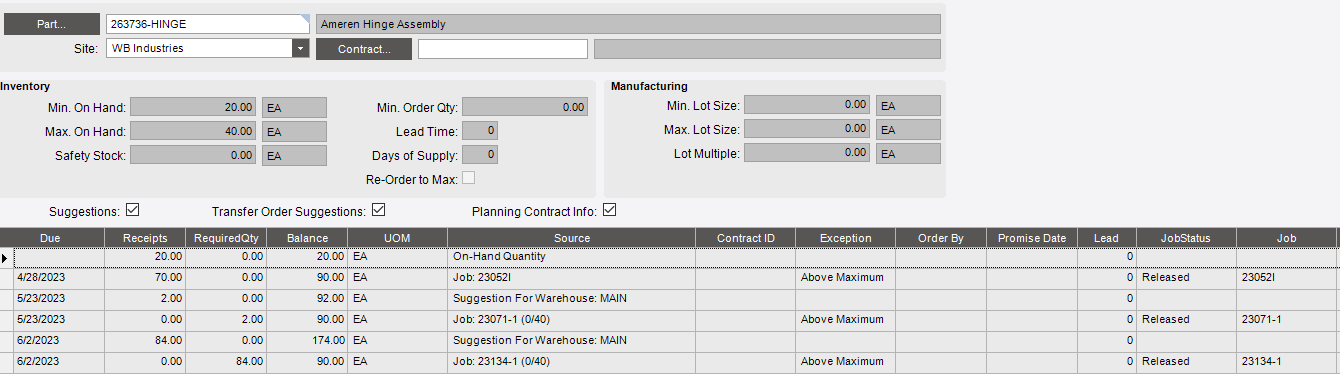

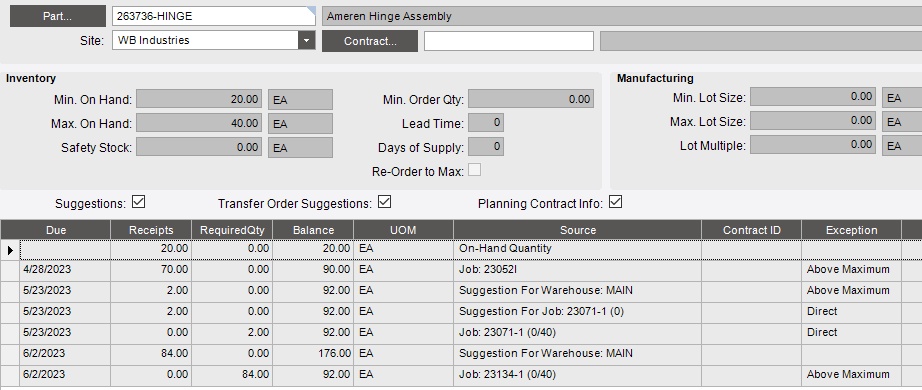

We have 20 in inventory currently and a job running in house (make to stock link) for 70. This would give us 90. We have two more jobs running that will require this part for production. One job needs 2 the other needs 84. The 90 should obviously cover the amount needed.

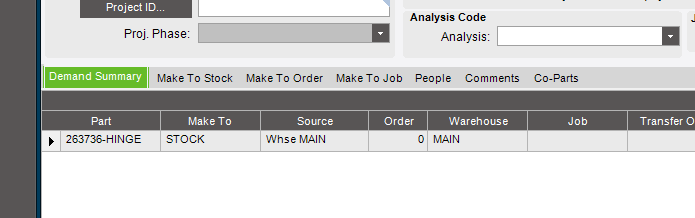

The issue is that we there are suggestions showing up for us to purchase the 2 and the 84 for the jobs where they are needed even though we will have the 90 in inventory to cover this. Any help on why this is happening?

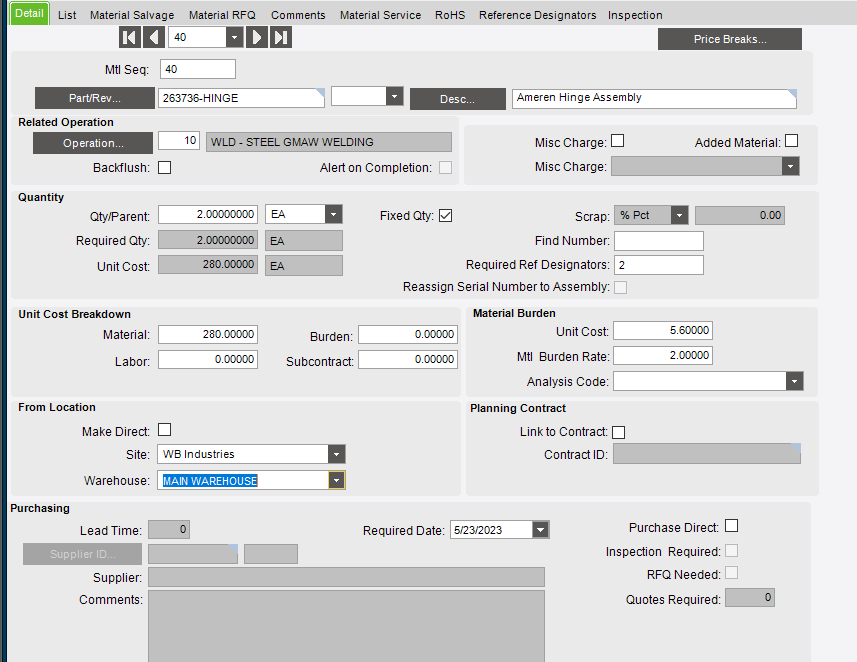

Are the materials marked as make direct on the jobs?

They are not marked as Make Direct or Purchase Direct. I tested checking both and it created ANOTHER line for 2 more.

Check the planning tab of part maintenance, make sure you dont have any lot sizing or multiples.

No lot sizing or multiples.

Are you multi-site? Do you have any thing set up for the part on the Main warehouse?