In our raw materials we are using forgings with given Length, OD and the bore. Epicor keeps up with total length of the forgings per bin location. So, if we have 3 forging with 5 inches length each, all we will have is 15 inches of the forging recorded in Epicor. The problem is, by looking at data only, we don’t know if these 15 inches are 3, 5 inch pieces or 5, 3 inch pieces. It is critical to know that because that will determine what we can make from it. The question I have is if there is a place in Epicor where we can keep up with each individual forging(part number) so we can know what each individual forging length is. It looks like Epicor is constrained to 1 part number per bin location. That is why even if we have several pieces of the same part number, total length is displayed. Please advise. Thanks

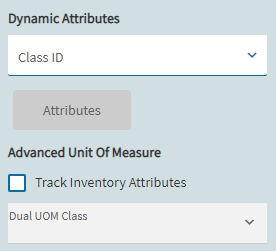

You will need to purchase the Advanced UOM module to do what you are asking. It is well worth the price if you really need it (and it sounds like you do).

We do have UOM present in material definition and it is in use. Is that not what is it? Do you have a screenshot?

Thanks for the info.

I looked online about Advanced UOM. From what I gathered in Advanced UOM basically you setup the qty of UOM. Like 10’ of length or something like that. If I see it right that would not quite work for us since our length can change in increments of .25 of an inch or so. What I was hoping for was to setup somehow the ID of the forging and have Epicor manage the length of that as it is dispersed. Kind of following concept of the Serial Number.

Serial Numbers button is available on the screens. Wonder how that would work.

Hi John,

Thanks for reply. I have posted my reply on e10help.

The AUOM will do exactly what you need. It is a little confusing at first, but once you learn it you see how powerful it really is.

When you create a Part with AUOM, you assign a Dynamic Attribute Class to it. You define what the class is and what attributes you want to track. When you enter a quantity into stock, you have to enter the attributes. So, in your case, one of your attributes would be length. If you set it up correctly, you will be able to track inventory as pieces but you see what the attribute set is in stock. So while you may have 10 forgings in stock, you will be able to see that 2 are 5 inches, 3 are 4.5 inches, and 5 are 4.75 inches.

Thanks John

That is exactly what I need. I need to find out if we already have it. Thank you so much.

John, one more thing. Will that keep up with the forging and it’s attributes as it is tied to the bin location?

Yes, the attributes carry through the system for the complete life of the part.

Thank you. Now comes the hard part. To get management to go along with that. LOL

I hear you. I have worked in sheet metal for a few years and have understood the issues that come with the industry (and any other similar ones like yours). The AUOM is an absolute game changer for it. They added AUOM through the whole system. So, if you order something in different sizes, it can be used in POs. When building the method, you can call out the exact size of material you need. It is truly amazing.

They have not completed everything yet, though they are working on it. We are still waiting to be able to put mins on attribute sets.

Right now, we need to track something called HEAT NUMBER on the forging and it can be different from forging to forging, even within same PO. We do not have place for it, but I can see that with the attributes we should be able to do that. I am after it because even thou I can write .net app, but with attributes, all of it would be in the Epicor, accessible to anyone. Hope management will go for that. Thanks

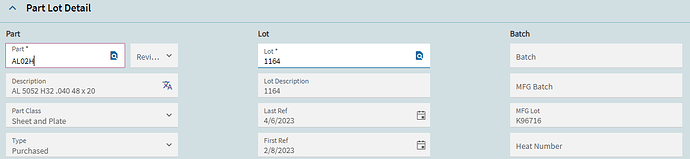

Yes, HEAT number is very important in metal. Don’t forget about using Lots in Epicor. That is the much easier and better way to do HEAT tracking.

When creating a lot with one heat number would user need to add individual forgings to it? Aside from Epicor system I am just trying to visualize how conceptually lot would be populated.

I have to say that I do not understand what you mean by forgings.

The way we are set up, we have lot tracked parts use a non-part specific lot. So when something is received and we generate lots, it just increments the last number. Then, we use the Mfg Lot attribute to enter the HEAT number. We could have used the HEAT Number field, but we didn’t. So, basically you end up with a part in stock having a lot number and if you look up that lot in lot tracker, you would see the heat number.

Forging is basically iron ring with OD, ID and width. We can order number of them, like 3 or 5 on the same PO. Anyway, each of them will have HEAT number that comes from the foundry.

All the forgings that will come in may have same HEAT number or different ones. So imagine 5 of them coming in. Each has width of 10 inches. Each one of them will be consumed in production process.

One forging will be made into lets say 1 inch wide part and that 1 inch part will cut off from the forging. So 9 inches will be left. Then we will made some other part 2 inches wide so 7 inches will be left and so on until all of it will be gone.

So we need to be capturing decreasing width to reflect the state of that forging. The record will be made in Epicor about this individual forging, like you suggested with AUOM.

As far a the HEAT number is concerned you suggested using Lot. I wanted to know how using HEAT Number in lot will reference a particular forging that right now will be 7 inches wide.

Just gives me a headache thinking about it.

Lot is definitely the way you want to go (if I am understanding correctly). Let’s just keep it simple with 1 piece.

So, you receive in the 1 10 inch piece and assign a lot number to it and put the heat in one of the attributes. That piece goes into stock with the lot number (and heat). It then gets issued to a job (either an inch or the whole thing, not sure of your process), when it is issued, you must select the lot number (with the heat behind it). The remaining 9 inches is kept in stock (or returned from the job) and Epicor still knows the lot number (and heat behind it). No matter what you do in the system, the lot number stays with the material. The only way you could lose it is if you did a quantity adjustment.

So the data will follow like this:

PO → Material Received → Lot Number → Part with Particular Attribute. That should point to a particular piece of material within a PO?

So, if I have multiple Heat Numbers that came in on the given PO I will need to create multiple Lots, correct?

Correct. If you get multiple heats on the same receipt for the same part, you actually have to receive them on separate lines.