Due to inventory and UOM Issues, I need to remove all inventory and change the UOM’s. When trying to qty adjust the parts out, the FIFO parts give an error of This transaction will result in a negative FIFO onhand Qty. Since we are still not live in Epicor, we have zero demand, orders, po’s…nothing.

Just taking out on hand won’t likely allow you to change a UOM. I had to stop even setting standard costs on new parts so they could be fixed or deleted if wrong.

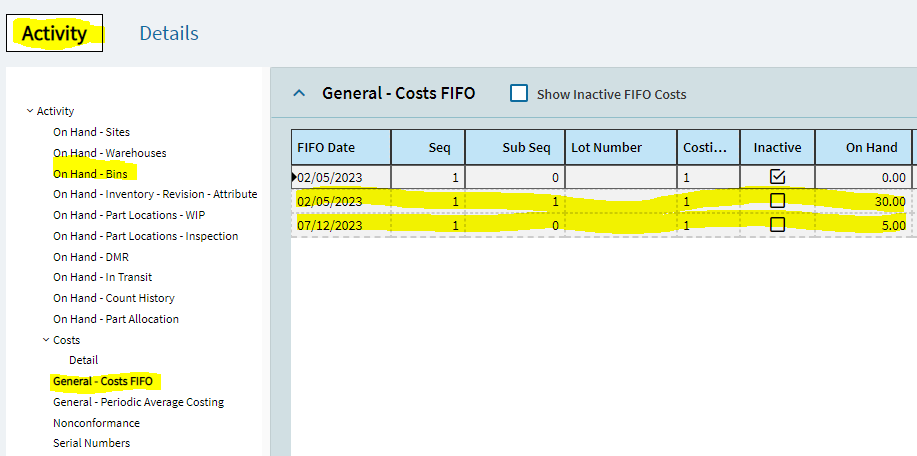

In part tracker look at the bins and fifo layers under the General > Costs > FIFO tab. if they are misaligned then you sometimes can take the quantities out in quantities that are in a layer. This will also make more transactions which also make it less likely you can change a UOM.

How do I access this area in Kinetic screen?

Tabs now run down the left hand side. I don’t have a UX install running now, so I can’t tell you the exact spot.

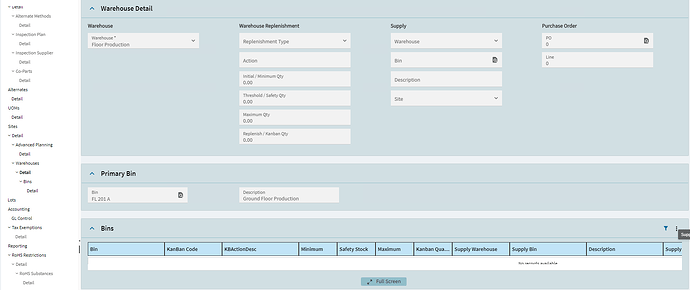

Seems the FIFO tab is not longer on this. Here’s a clip of my part tracker for this part. Interestingly, I have a prim bin, but there isn’t anything in the Bins.

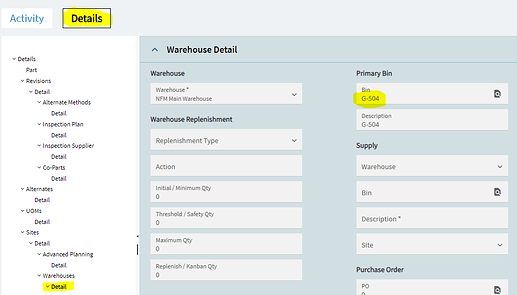

You can set the Primary Bin on a part… this sets a default Bin. However, the part can still be received into any bin, any where, any time by users making various transactions. So, don’t assume inventory is only ever going to be in the Primary Bin. Someone could receive it somewhere else. Below is an example:

Primary Bin set to G-504

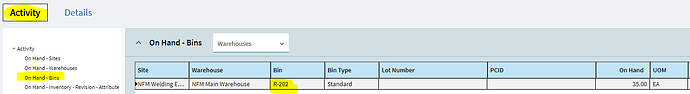

Actual inventory being held in R-202

That all being said, I think @gpayne is correct, that just removing all inventory of a part will not free it up to change the UOM. I’m pretty sure making ANY transaction against a part will lock in the UOM. That’s why UOMs are critical to have correct in early-stages.

Since you’re not Live yet, you’re at least in a situation where you could potentially delete this part and recreate it with the right UOM. But that is tough if you use this part in BOM’s/methods as you’d have to make sure they all get fixed as well. There is a “Part UOM Conversion” menu/process that you could try. This may work for simple changes… but I’ll admit, I’ve never attempted it. Based on the application help, you do need to make sure you have no on-hand inventory and no active transactions for the part.

On Part Tracker (Kinetic)… note there are two main “tabs” (which don’t really look like tabs, so I think they’re often overlooked by users new to Kinetic screens)… “Details” is the default… but there is also an “Activity” tab.

So, check Part Tracker > “Activity” tab > On Hand Bins… and see where your inventory lives. Then you can try to adjust it out.

In the above example image, I’m looking at the “General - Costs FIFO” screen… I have two “active” FIFO layers for this part.

- 2/5/2023 Seq 1, SubSeq 1 > Qty 30

- 7/12/2023 Seq 1, SubSeq 0 > Qty 5

Looking at the “On Hand - Bins” (see image above)… I can see I have Qty 35 in Bin R-202.

To remove the inventory, I had to get a fix from support. But you are correct, the IUM is still greyed out. I checked where you mentioned and I have zero qty anywhere. Ideas on how to pen the IUM, or do I need to delete and start over? There are not BOM or BOO yet, thankfully.

You have PartTran records so deletion is already out. If you want to change the UOM conversion and it is very early and you have very few records there is a workaround that the Has been used checkbox was able to be reset and then you can fix the conversion factors. I made a ubaq to unset the has been used rather than doing it in part maintenance. If you want to change the UOM Class that requires using Epicor’s UOM Conversion that @dcamlin mentioned.