I’m having a hard time understanding the point of the Resource Output Warehouse and Bin designations.

I was led to believe by implementation consultants that Time and Expense entries against a Job Operation that links to this Resource (and further, for a Job whose Demand Link pointed to this warehouse) the auto received inventory would increase at this location.

I’m finding, however, that the Output Warehouse/Bin on the Resource Group isn’t factored in the heirarchy at all. The only place it ever increments inventory upon Time and Expense Entries, is the Default Bin in the Demand Link Warehouse.

For example, I have my Resource Set up with an Output Warehouse & Bin (00000000) as such:

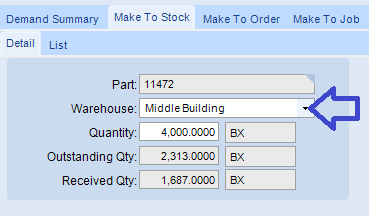

In the Job Record, I pointed the Demand Link to the same Warehouse:

However, when I do a Time and Expense Entry against this Job:

The Part Transaction History Tracker shows it went to the right warehouse, but a different Bin:

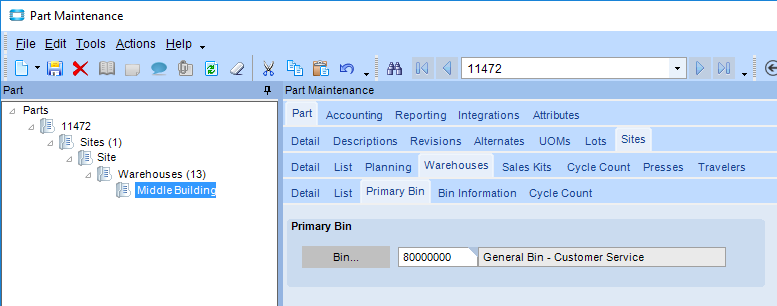

The bin that was incremented (Customer Service) was the Primary Bin in the Warehouse called by the Demand Link:

Does anyone know exactly what the Resource Output Warehouse and Bin is used for, if not for what I was expecting it to be?

Or any thoughts on customizations I could build to reroute inventory to the bin called out on the Resource?