We have not been using the QA module as intended, I am trying to run some production parts through the proper nonconformance process. I began a non-conformance, I failed them in inspection processing and now I am on DMR. How do I tell kinetic that we reworked the parts? I didn’t see an area to specify this in any of the steps. We also do not use the “corrective action” module. Inspection data/results is not available to me either, so is this not working how I want it to because we do not have the enhanced QA module?

Thanks for any help!

Welcome @cdeblaere !

The way that I have interpreted how to use the Quality functionality is this way (not even sure if this is what Epicor intended ![]() ).

).

- Production Worker NCRs a part off of a job with a reason code.

- Inspector reviews part. If it can be reworked, accept back to job for rework. Else reject to DMR.

- DMR reviewed. If it can be reworked, accept back to job for rework. Else reject.

In your instance, I would put the comments on how to rework it in the Accept comments. Then I would instruct the worker to log into the same Operation and click the Rework flag to denote that time as rework.

Welcome again @cdeblaere!

To expand on what @jkane says, in your specific case you would need to first create a job with operations that will fix the item, whatever OTHER materials are required (if any), and this actual item as a material… so you have a job where the OUTPUT is the same as one of the INPUTs. It’s a logic trap, but it works. From the DMR Processing screen, open your DMR and go to “Accept Material Details”. Click the + to create a new record, and enter your Job Number, Assembly, and Material Sequence along with quantity to “issue” this material OUT of DMR and onto the job. Complete the job as any other job and accept this part back to stock when done.

@cdeblaere I concur with the other two responses.

But something you might find helpful is setting up appropriate reason codes for DMR Accept that will provided the Reason for the Accept, in this case something like ‘Reworked.’

The other option is to Rework the parts on a different Job, or even a different Operation on the same job that is for Rework, or be sure to mark the Labor Entry as rework, which can help those reviewing the Job to understand why the Actual Job Costs are higher.

This makes so much sense and honestly feels really obvious in hindsight haha. We do not have “jobs” for the rework or a rework reason code so we will be setting those up

Thank you!!

Hi John,

I’m struggling too finding anything of value about getting DMR materials reworked into new jobs, at different resources.

So we may run off 100 of something, and realise that the last 20 were not the right length, maybe too long, so we cant put that material back into the same machine, but can cut them down by hand

So it would be “a new job linked to the DMR’d material” that’s not either rejected or accepted, but is requiring a new job and engineering, to then be put into stock or related back to that job quantity that was already being run through, if that cant be done, just a way to say “we have some we need to rework on a new job, schedule them reworks into that resource over there when they can be done” as currently we don’t schedule rework and its just a mass of parts stacked up until the day comes we jump on them all in premium hours, instead of utilising resources availabilities.

we are using pull as assembly, and trying to maximise guided handheld scanning transactions and bits like that so its all guided, not people being expected to know what to do… unfortunately

Sounds like you need to map out how you want your process to flow. Epicor should be able to handle whatever you come up with, but you will need to define what you want first.

As an example, let’s say you determine a DMR can be reworked. Like you mention, it needs a different operation than what is on the current job. You can add the operation right before whatever the next op will be. You could create another job and do a make to job link. You could even add it as a subassembly on the current job.

Sorry to punt on the answer, but I am not really sure what your question is.

I got inspired by your text and I rewrote our DMR handling to make it work. We had a similar issue. We have a lot of open DMRs, and therefore, open jobs that cannot be closed until the DMR has been resolved.

Ideally, we would like to transfer the DMR from the old job to a new job with the product’s serial number, and then engineering/quality can work with it. That would mean the old job can be completed and closed, and the cost can be calculated. Our DMR list is so long, and the value of DMR is a few million, and that is really annoying for finance for understandable reasons.

How it works now:

- A product with serials is reported as non-conforming on operations on the original job

- Then it moves to inspection, where the shift leader decides based on the reaction plan, what to do.

- Inspection failed = SN moves to DMR

- In DMR Process quality engineer will decide if we can rework

- If it is possible to rework then he will accept the SN as job MATERIAL to a existing job. This means the SN will move from original job to the new one.

- The new one has one operation for rework, and the material is the same product, allowing serial numbers to be reassigned

- The serial number must be assigned to the rework job

- Reporting the serials and operations as usual in MES. If the rework was successful, it is reported in operation and can be taken to stock.

- AS soon as the SN is sent as job material to the rework job in DMR, the original job can be completed and closed without the DMR warning/stop.

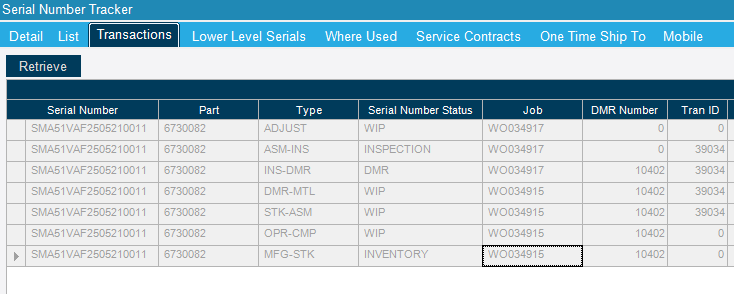

Materials needed for rework are added to the rework. The only issue remaining is the original job’s excess materials, which need to be returned and reissued to the rework job. But we do not have that many materials, so this will not be a big problem for now. On Serial Number Tracker looks like this:

I think it’s important to talk about the intended use of this process, because I think it is easy to make some incorrect assumptions. We have done it here at my company.

The initial Nonconformance/Inspection step exists only to determine and communicate if a part is out of spec.

Yes situations exist where out of spec parts can still be used, but that conversation is not a part of the initial inspection process. How often I buy or produce parts that are out of spec is an important QA metric.

All out of spec parts should be failed to DMR. DMR processing is the appropriate place to determine and communicate what we are doing with the part. We are living with it and using it anyway, it’s not a total loss and can be used for some other purpose, it has to be returned/thrown out/etc.