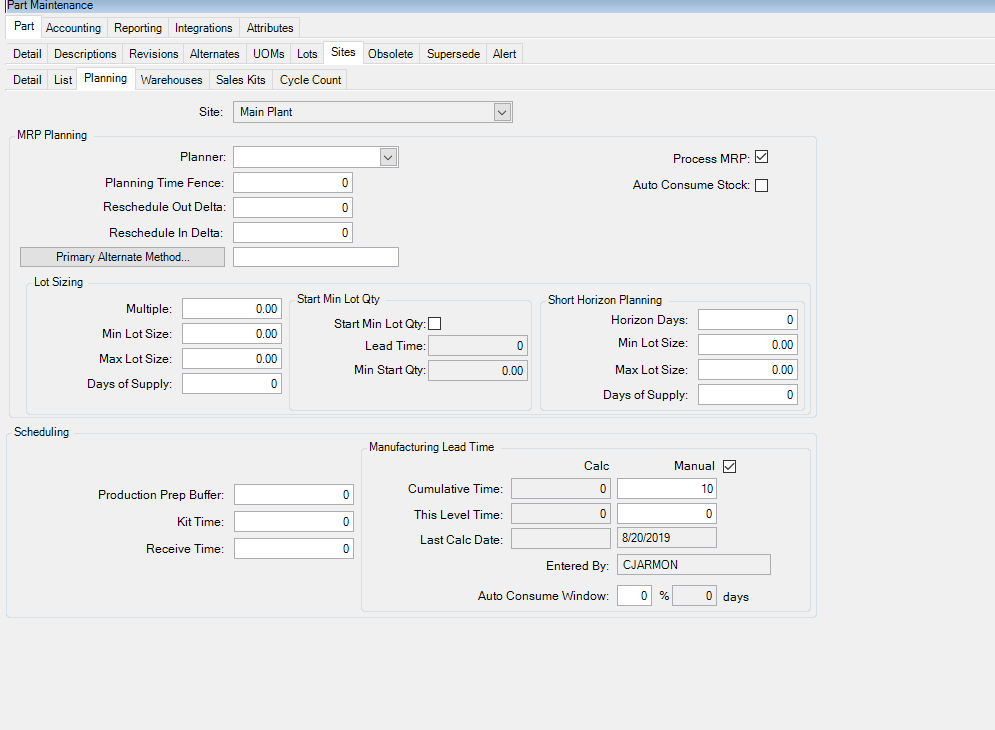

I recently joined a new company and they are currently looking to use Epicor to its full capability. Unfortunately they are still in the infancy stages in regards to accurate routings and standards for production. Because of this, when Epicor creates a manufacturing suggestion it will have the unfirmed order be suggested to start and finish the same day as it is needed for production. Until we have enough resources to get routings and standards in place I believe we could utilize manufacturing lead times to back date start dates to give a thumb gauge on a rough cut capacity. I recently assigned a PN a 10 day Cumulative time under the header of 'Manufacturing Lead time". MRP ran last night however the MRP suggestion is still showing it to start and complete on the same day the REQs are needed. Is anyone aware how to utilize manufacturing lead times to back date start dates for manufacturing suggestions? Thanks in advance for any insight!!

Any help is greatly appreciated!

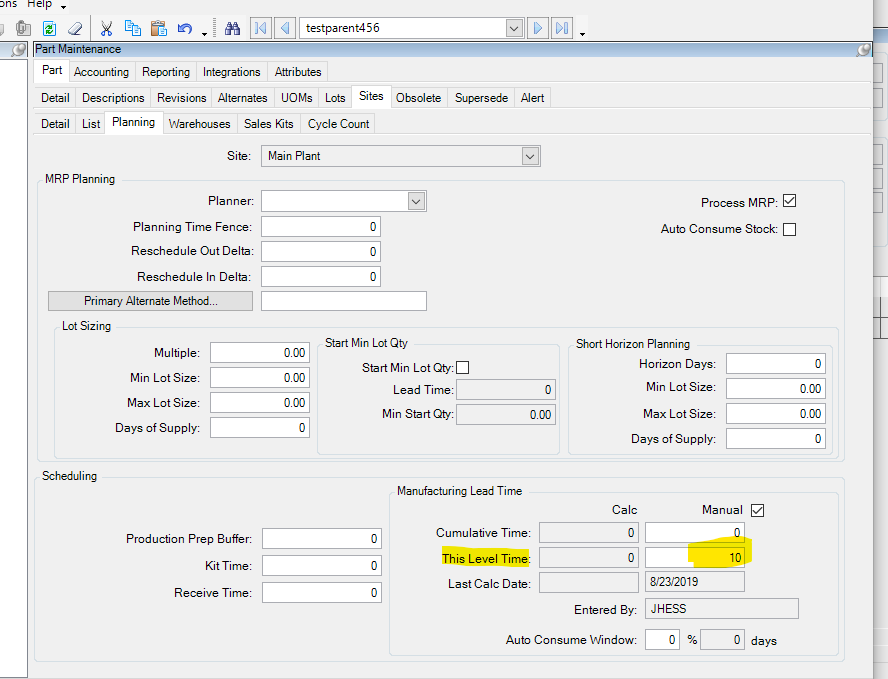

I believe you need to enter the 10 in the This Level Time. The way Epicor works is that for each subassembly, it calculates the This Level Time and each level it goes up it does the Cumulative of all of the This Level.

Try populating that and run MRP for that part only.

Thanks so much John! I will give this a try right now. Have a great weekend!

@jkane unfortunately this did not work after MRP running over the weekend. Any other ideas? I scheduled a job for a Req by date of 9/27. This part has a setting of 10 days for “This Level time”. That being said, when MRP ran I was expecting it to have a start date (10 business days prior) 9/13/19. In addition, I would expect my raw material requirement to be 9/13 or earlier and the raw material requirement is 9/27. I am looking for Epicor to back date its start date according to our in house production times until we have our routings and standards in place.

My bad, I should have told you to keep the cume at 10 also. The cume is the sum of all levels and therefore would need to be 10 since the current level it is on is 10.

Did you ever get this figured out? I want to do the same thing since that is how I am used to seeing MRP work.

You can use the fields to left if you just want to manipulate the start/end dates. Production Prep Buffer will push out your start date x number of days. Receive Time will schedule the due date x number of days before the Required by date.