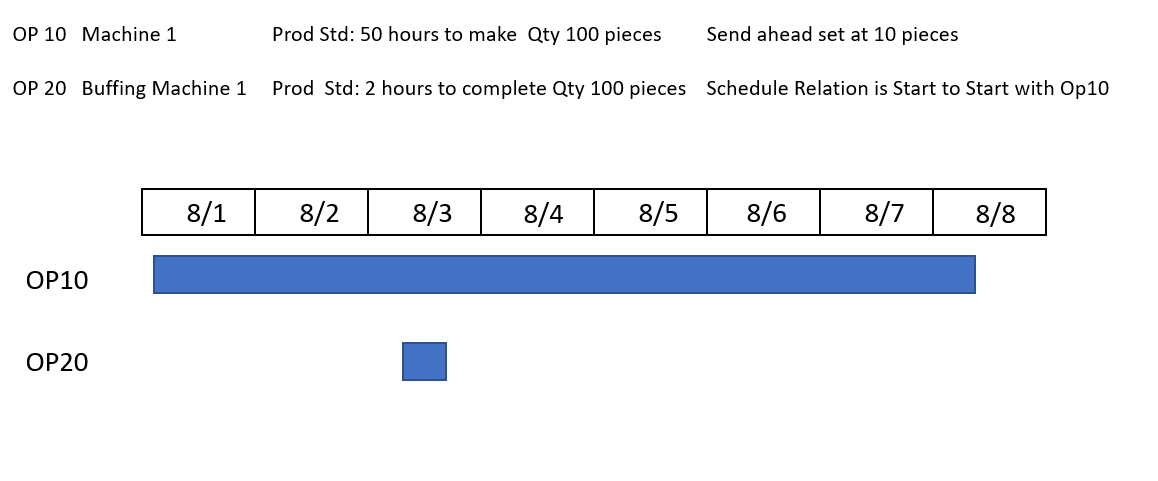

I have a machine on OP10 that is producing pieces over a 50 hour block of time and is anticipated to be completed on 8/8. The Send Ahead is set to 10 pieces.

OP20 can begin as soon as the first 10 pieces come off of OP10. But OP20 is super fast. it will only take 2 hours to do the whole batch, so Epicor is scheduling all qty to be completed on 8/3, before most of the qty will even be done on OP10. We want OP20 to be scheduling based off the send ahead QTY of 10… so there should be some OP20 time on 8/3, some more on 8/4, some more on 8/5 al the way to the last pieces come off on 8/8.

How do we accomplish this? Im stumped.

Perhaps an obvious question, but why send ahead for an operation that has a significantly smaller run time?

Have you considered smaller job quantities?

This is very common for machine shops. Because typically a machine has a limited capacity number it can run, like 10 at a time. They dont want the second op to wait until all 100 come off the OP10 machine. They want the second process to start processing quantities as soon as they are available from the proceeding OP.

They could break these into smaller job lots, like jobs of 10. But instead of managing one job of 100, now they have to manage 10 jobs of 10. They dont want to increase their data entry burden because of a limitation in the software.

I would argue and say this isn’t a software limitation, but faulty programming in the Epicor schedule engine. There is no way physically that all 100 pieces can finish on a Tuesday when the full quantity is not showing to be avaiable until Friday. That does not make any logical sense and would be impossible in reality.

I don’t see a bar code swipe for labor entry as a significant impediment to maintain your schedule integrity. But, I do see your point. If you want the schedule to function properly, you might have to adjust your thinking. The unfortunate reality of ERP systems. They do have their limitations.

New user here so hopefully not a silly question…I’m trying to build in extra time to an operation without adding actual production hours. For example, I want to give my QC group 36 hours to process an inspection before the next machine operation is scheduled to start, even though the inspection itself should only take 2 hours. I think ‘send ahead’ by hours might be the opposite of what I’m trying to do but its the only option I found that seems even remotely applicable. And help would be appreciated.

Hi @RNBRO66

You could utilise queue move times, this is set at the resource group / resource level.

This would achieve a scheduling essentially offset from the end of the previous operation to the start of the next.

If I remember correctly send ahead is mainly utilised when overlapping operations

Eg if you had 4 parts that took an hour each and you used a send ahead of one hour then the operation would be scheduled when the 3rd part of the previous operation is expected to be completed.

Another factor that would play apart in the above is the scheduling relationships of the operations ie start to finish , start to start.

@RNBRO66 Welcome. We use queue (inbound hold) like @ridgea mentions for this with our final audit. One caveat is that this applies to all operations in this resource group. You could make another resource group without a queue time for other QC operations if that is an issue.

thank you for this. We’ve employed this and its doing as we required.