Hey folks. First time poster here, preparing for a Go-Live in January. This is my first rodeo, so still learning best practices.

I’m looking for suggestions on handling sub-contract operations for sub-components in an assembly method, specifically integrating them with PO suggestions.

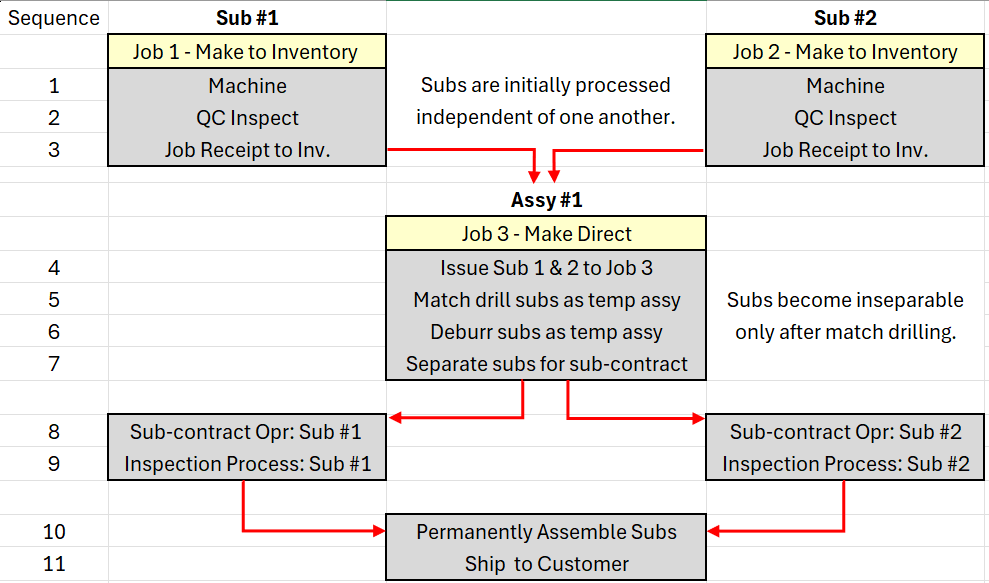

The scenario:

- The assembly includes two manufactured sub-components, each machined on separate jobs and stored in inventory.

- A new job pulls these sub-components from inventory for assembly, where they are match-drilled.

- After drilling, the sub-components need to be separated and sent out individually for sub-contract operations (e.g., painting) using their respective part numbers. Their respective processing happens in parallel.

Here’s an illustration of our legacy process:

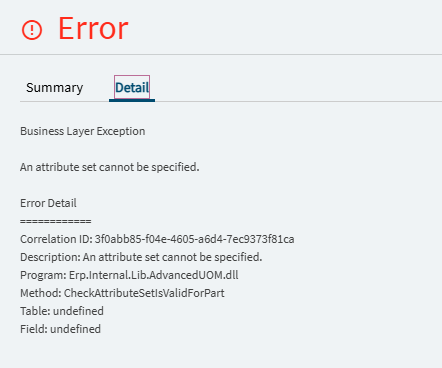

I’ve considered creating two back-to-back sub-contract operations on the assembly method and specifying the sub-component part numbers for each operation. However, I encounter the following error in Engineering Workbench when trying this:

We aren’t using attribute sets or Advanced UOM, so the error has me baffled.

Error aside, am I approaching this the right way? Is there a better method for configuring the assembly to handle separate sub-contract operations ?