Hello,

We’re reaching out to the community regarding a subcontract process we are trying to work through.

Often times we have to send out job material for outside service. For example, job material needs to be heat treated.

We’ve tried a couple of different things.

Scenario 1

- Add a subcontract operation for heat treat.

- Add the material to the method and/or job that requires heat treat and associated the material to the related subcontract operation.

- Since the subcontract operation is for the top level part and not the material being sent out for heat treat, we simply added operation comments which flow to the supplier PO indicating the part being sent for heat treat.

This is not ideal as the purchase order calls out the top level assembly part number and not the actual material we are sending out for heat treat.

Scenario 2

- Add a subcontract operation for heat treat.

- Add the material to the method and/or job that requires heat treat and associated the material to the related subcontract operation.

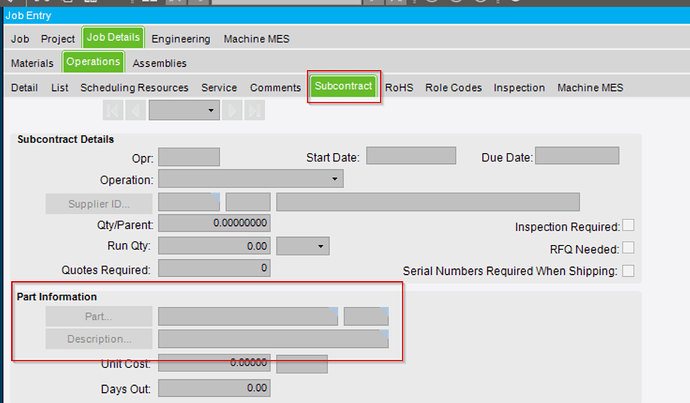

- Change the part number in the Part Information section on the subcontract operation to the material we are sending out for heat treat.

By changing the subcontract operation part number, the correct part number flows to the subcontract purchase order. Problem solved, or so we thought. This process works for us IF the material coming back from a subcontract supplier passes inspection. If the subcontract work fails inspection and a nonconformance is raised against the subcontract operation, the nonconformance defaults to the top level part number, not the part number we identified on the subcontract operation. We understand why the system is behaving this way but now need to find another path to process these type of subcontract ops.

We’ve considered creating a subassembly for the material that requires some kind of vendor processing. The subassembly would have the subcontract operation and the associated material. This will absolutely work but we are questioning if there is another way or some functionality we are missing.

Please let me know if anyone has run into this and has any suggestions.

We appreciate any feedback.

Thank you!

Laura