Is anyone tracking Tool Calibration in E10? If so what modules are you using and how is it working?

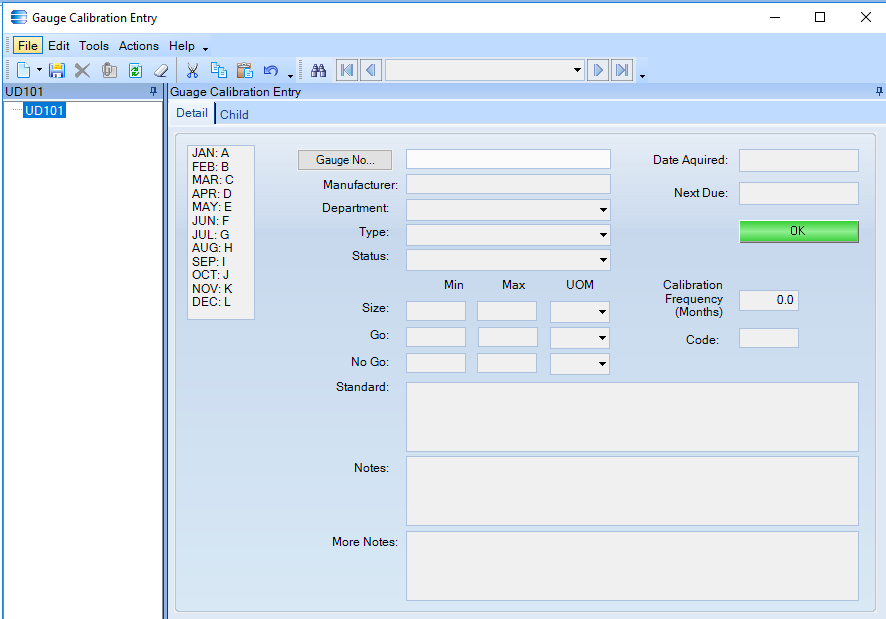

I’m anxious to see who else replies on this because my customers had to repurpose a UD table to store tools, calibration dates, and calibration history.

It seems that the Maintenance Module could work. If your calibration is time-based then you enter the tooling as Equipment and set up a PM schedule. If it’s usage-based, you would make the PM Meter based. I haven’t done it but it seems possible. One benefit would be the maintenance jobs would give you a history of calibration and track the costs if sent out for calibration.

@Mark_Wonsil +1

I have setup one client with the Maintenance Module for Calibrations, and it worked pretty well.

You can create Equipment Records with all the details, Mfg, Make, model, year purchased, Specification notes, Comments, and the ability to define equipment parent/child relationship.

At least at the time to use calibrations you had to own the Maint & Enhanced QA module since the Calibration depends on an Inspection Plan and a Specification. Only other downside at the time was that there wasn’t a built in way to set calibration frequency (though it does keep track of last calibration date) and no way to then know when a calibration was due. To accomplish this I just added a UD Integer field on the Equipment table for frequency and a Dashboard that would show Equipment due for calibration and coming due (say next 90 days). This ended up working quite well and for the IOS audits they were quite happy with the record keeping.

@Rick_Bird

We recently purchased the maintenance module and enhanced quality. I am getting ready to set this up. Our consultants recommended using a regular maintenance plan to execute calibrations. This allows us to use a maintenance plan to schedule the calibrations. However, we lose the use of the “Last Calibration Date” field.

I’m interested in a comparison between the 2 approaches.

If I set a calibration inspection plan on the equipment record, where do I execute it? On a maintenance job? If so, can’t I combine the 2 approaches and set a maintenance plan with a template job that uses the calibration inspection plan?

@rad.russ15

The Calibration Process is covered in the Enhanced Quality Assurance Course Guide, it has it’s own section.

Basically, you have to:

- Create Inspection Attributes

- Create Specifications

- Create the Calibration Plan

- Setup the Inspection Configurator for the Calibration Plan.

- Assign the Calibration Plan & Spec to the Resource\Equipment

- Enter Calibration Inspection into 'Inspection Results Entry’

- Review the results in the Inspection Data Tracker.

- Note the Last Calibration Date field updates in Resource\Equipment Entry

We are trying to set calibration up as well. We have the maintenance module but do NOT have enhanced quality. Our plan currently is to add a UD field to the equipment maintenance screen to hold the last calibration date and then using the frequency on the maintenance plan tab have the next execute date serve as the calibration due. We have a dashboard that was deployed as part of our Cre8tive A&D bolt on that we will rip apart and rebuild with our UD rather than the Enhanced quality field. Fingers crossed it works as planned.

Our company is looking to add a “calibration module” into Epicor. From what I have read above enhanced quality gives the ability to add inspection data plus a few other features. We use our calibration module as a log to keep track of external calibration and a few internal calibrations as well. At the moment we haven’t kept individual inspection data, rather a pdf is uploaded into the log. Would using the Maintenance module with an added UD field suffice for our use of “calibration”, or is the enhanced quality module needed. @Rick_Bird

@Wes_Johnson my recommendation is Enhanced Quality module.

The main reason I prefer a module built for the purpose is to reduce effort required later to maintain any custom UD field solution. If you have the internal resources to maintain your customizations, then it might work, but if not and something breaks then you will need to get someone to fix it.

Would this work in tandem with the maintenance module? Or can enhanced quality operate without it. I understand the benefit of having enhanced quality over adding UD fields in the maintenance module, but is it worth the price value of adding enhanced quality just for calibration? I am using calibration loosely, as we farm out our calibration and would not be inputting inspection numbers in, just pdf’s @Rick_Bird

Yes, it is designed to work in tandem with the Maintenance Module when calibration tracking is required for maintenance items. Enhanced Quality does not require the Maintenance Module to be used for other functions such as production jobs.

Depending on your calibration tracking needs, you may not be able to leverage the Enhanced Quality Module for calibrations. If you are not intending to enter calibration results and only attached a PDF document, you can already do that with just the Maintenance Module. In Equipment Entry you can attach all the documents you like. If you just need to track the last date a calibration was done, then a single UD Date field per Equipment record might be all you need. But if you end up needing to track the calibration results beyond half a dozen fields, then Enhanced Quality Calibrations could be a better fit.

Did this ‘Last Calibration’ date UD for a client once and then to make it useful, created a Equipment BAQ Search that displayed all calibration dates that were of a certain age, which gave the manager the Equipment that he needed to gather for calibration.

Hoping to move our Tool/Gauge management from IQS to Epicor Maintenance Management.

Equipment is defined; plan is to use maintenance plans to handle the calibrations. We do also own Enhanced Quality so Inspection Plans for calibration are possible.

Main question is how to capture where-used information?

Looks like we should be able to capture that thru Equipment on End Activity, but I don’t know if we have security blocking us or a configuration not quite right.

Welcome back @jbillet!

There is no out-of-the-box “where used” report for Resources (or Resource Groups)… but the data you want would be in the JobOpDtl table (which stores Resource/Resource Group information for each job operation). Depending on what other information you want to include, you may also want the JobOpr, JobProd, JobHead, and maybe Part tables.

To see what MOMs include them use PartOpDtl (child of PartOpr, child of PartRev, child of Part).

I appreciate the quick response.

Didn’t want to have to create resource groups/resources for all our measuring devices. Additionally, multiple measuring devices can be used while performing work under one inspection, welding, etc operation.

Does anyone enter equipment via the End Activity on MES?

How does it work? What makes it work?

@Rick_Bird

We decided to go with both modules as our quality department saw use in the enhanced quality. Currently, I am setting up the maintenance module. Is there a way to auto release jobs? With how many items we are calibrating and pming I do not want to release every single job individually. I am just using one template job for all of them, so maybe there is a way to mod that. Let me know of any other tricks you have had with setting up the maintenance module.

There is no system setting for “auto-release maintenance jobs”. This would require a BPM, and which method(s) will depend on how the jobs are being created in the first place (Maintenance Plan Processor? Request?)

Hi

You can automatically release Service Jobs (as well as Production Jobs) using the Auto-Job Release functionality, but if you want to filter out Service Jobs from Production Jobs using this functionality then you will need to make sure you have a different “Planner” assigned to each type of job and then when you run the Auto-Job Release filter it on the planner for service jobs only