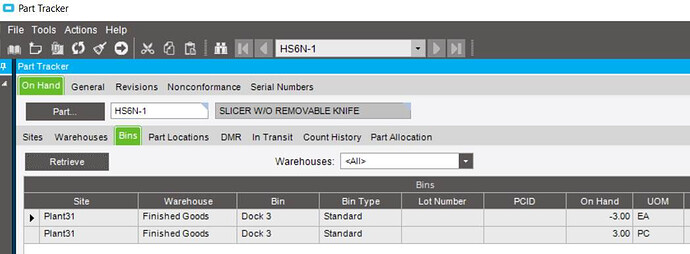

My inventory is all listed as “PC” on the Unit of Measure, however on Oct 29th several parts were changed from PC to EA in the middle of the day, and unsure who actually changed them. When this happened, it caused us to have Inventory showing in stock of “+3 PC and -3 EA”. We are unable to do a Quantity Adjustment to fix. Any help I can get on how to correct this would be greatly appreciated.

You are showing part bin on hand quantities of two different UOMs?

Whats the Part’s IUM?

where are you seeing the two different UOM on hand? Is it in Part tracker?

Yes that is correct, I am showing On Hand Quantities in two different UOM’s, in Part Tracker. I attached a Screen Shot as well. I am not sure what “IUM” stands for.

ok I figured it was in part tracker. What version are you on. There is an issue (at least there is in 10.2.200) with partwhse table not refreshing sometime the part bin quantities.

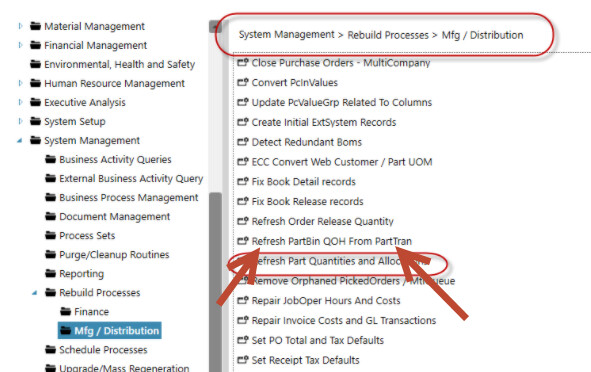

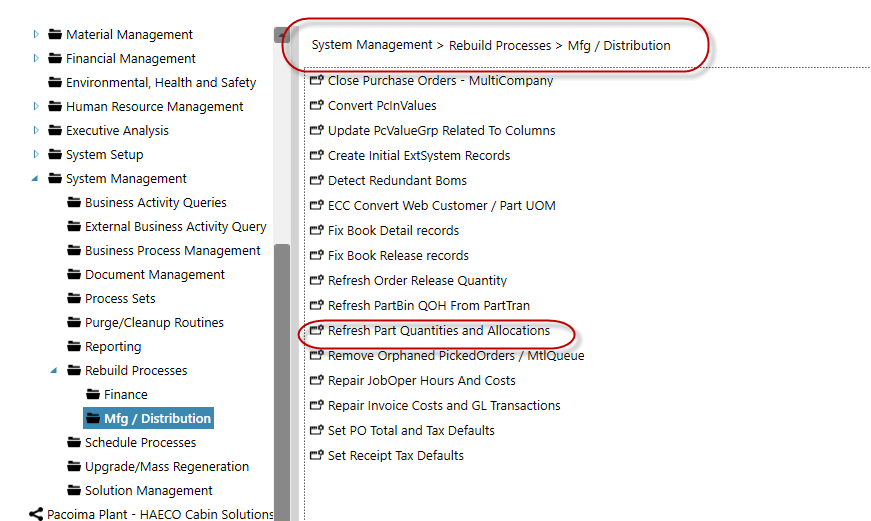

Try running the Refresh Part Quantities in a test environment for that part only and see if it fixes it.

We updated our Pilot version of E10 and I ran the Refresh Part Quantities and Allocations, and nothing changed. So we still have the same issue showing the same parts with 2 different UOM’s.

Some thoughts:

- Why can’t you do a quantity adjustment? It won’t let you?!

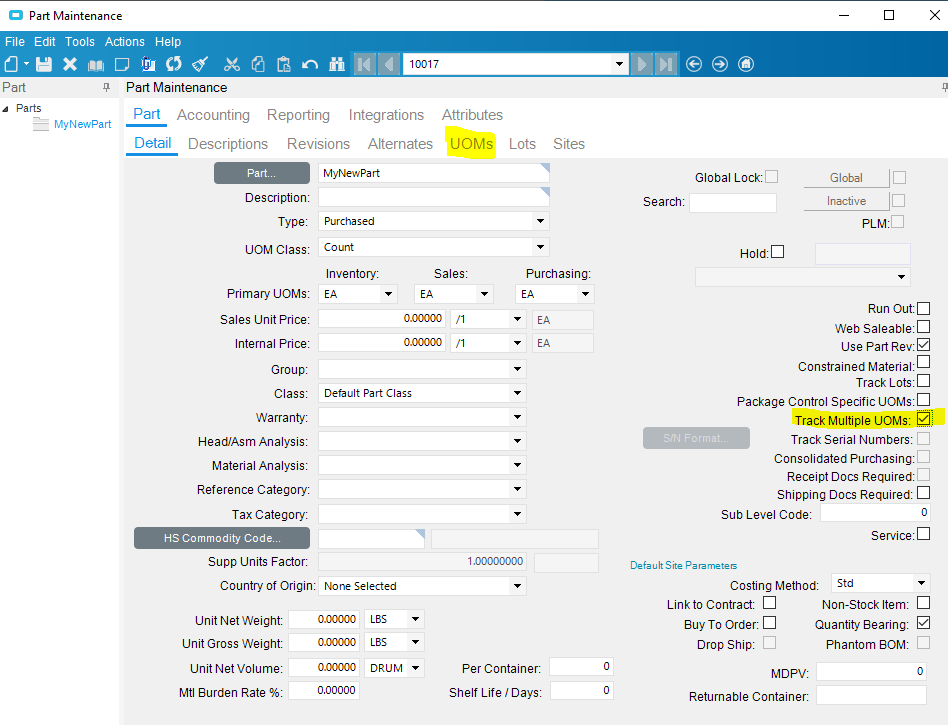

- I don’t know anything about using multiple UOMs on purpose, but it is a thing (pic below). I know that’s not what you want, though.

- Is it lot-tracked? (Long shot)

- Yes, this sure is odd.

Also, IUM is “inventory unit of measure.” See pic in previous post - every part has three kinds of UOM. Not to mention you can override it anywhere, too.

Rant: I kind of wish there was an Engineering/Production UOM, too. Tape measures are in inches but suppliers sell by the foot or roll.

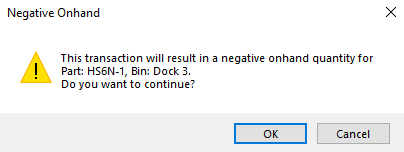

When I try to Qty Adjust, I get this error.

Also none of our parts are checked as Track Multiple UOM’s.

It is also not Lot Tracked.

Can you do the positive adjustment first? +3 EA then -3 PC?

Also the negative restriction is due to a setting on the part class, I think. Perhaps you need to turn off that setting if it continues to get in the way.

Are you multi-company and manage parts at a Global Company Level?

You can force push UOM changes down to a child company even if it has been transacted via Multi-Company. But thats prob not what happened here, just a quick fact.

Try the Refresh PartBin QOH from PartTran in your pilot environment. see if that does anything