This is hard to explain but here goes. We have been using Epicor to Cycle Count since February and have rolled it out to multiple locations. The issue we’re having is “predicting” if you will the number of parts that it spits out per cycle. We have done test, after test, and the numbers always come out very higher than anticipated. I have a ticket in with Epicor but haven’t gotten very far.

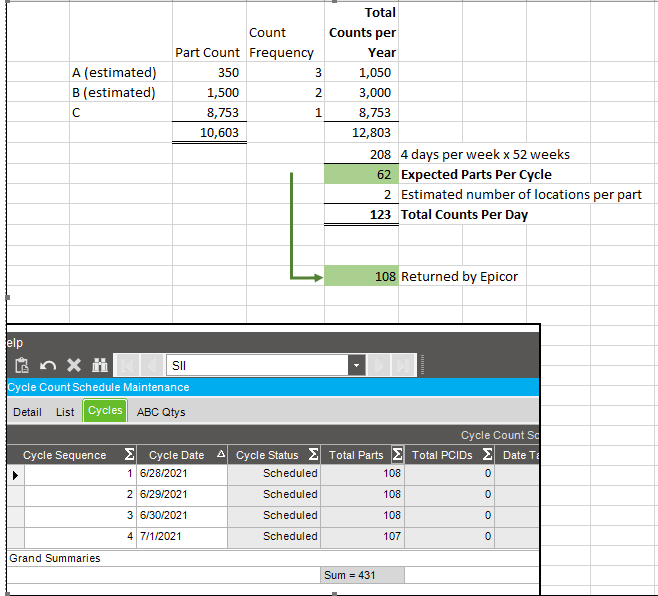

It’s hard to predict time, staffing requirements, etc when you do an estimated calculation based on on hand parts and then your counts exceed that by far. Here’s an example of an analysis we have done. To note: we use repetitive counts, I have ran the last cycle count date fix, and we only have 3 ABC codes.

you need to switch to “Random” instead of Repetitive… that allows you to specify the ABC QTYS (on the tab by that name) that you want to have. This will spread out your counts. The result is that it will not be exactly repetitive… it might count the parts every 5 or 7 months instead of every 6 depending on the number of parts you specify to count. BUT the “Random” method also gets rid of the “bubble” of parts to count… example, in Repetitive, if you count 1000 parts in march, then 6 months from now, you will probably count 1000 parts again… but in Random mode, it will spread the parts out to even out the bubbles.

Interesting… I guess I can’t tell you why we chose repetitive other than per its definition and advice from others in order to obtain the count frequency we desired (3-2-1) for the auditors. Does random still do that?

Random will still do the frequency as long as you dont limit your part count… example (Assuming monthly cycles):

Example Assumptions:

- you have 120 A items

- you want to count them quarterly

- This means that there will be 480 counts completed for A items (120 * 4 counts):

So… That said:

- if you specify to count 40 A Items per cycle, then you are good… (40 parts * 12 months = 480)

- but if you tell it to only count 20 A items per cycle, then after 1 year, completed 240 part counts. none of your parts will have been counted 4 times in the year.

- but if instead, you tell it to count 42 A Items per cycle, then some of your A items will be counted more than 4 times in the year. (about 24 parts will be counted 5 times).

Of course this is all estimates. in a real world, the system only tells you to count items that are actually in stock at the time. Sometimes there may not be a full 120 parts on hand, so therefore it flexes… but that is why it is called “random”.

Thank you Tim, for your insight!! I will review this with our team and hopefully we can make some positive changes.

Once you get through a year you can usually switch to repetitive once you get last count dates established.