Over the years I’ve had more conversations than I can count that go something like this:

“Tim, MRP is broken – it’s giving me suggestions that make no sense!”

In many of those cases, the issue isn’t the MRP logic—it’s the data that MRP is working with.

MRP is a Mirror, Not a Mind Reader

MRP isn’t a mind reader. It doesn’t know that your PO won’t arrive on time even though the lead time is wildly optimistic. It doesn’t know that your BOM yield is off unless you tell it. It doesn’t guess whether your forecasts are trustworthy. It simply looks at what’s in the system and gives you the best suggestions it can—based entirely on that input.

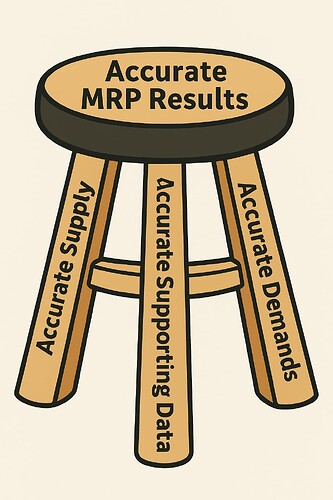

The Three-Legged Stool of MRP Accuracy

I often describe accurate MRP results like a three-legged stool. If any leg is wobbly, the whole thing topples over.

-

Accurate Demand: This includes clean sales orders, valid forecasts, and reservations/allocations that reflect reality. If your forecasts are inflated or you’re over-promising ship dates, MRP will react accordingly—with overbuying or scheduling panic.

-

Accurate Supply: Your PO and job completion dates need to be realistic. If you’ve got old jobs that haven’t closed or POs with overdue receipts that aren’t addressed, MRP assumes they’re still coming. That creates “phantom inventory” and bad suggestions.

-

Accurate Supporting Data: BOMs, routings, calendars, part planning parameters (min/max, safety stock, lead times, etc.) all play a huge role. I’ve seen MRP misfire simply because a BOM scrap rate was 0.1% off. It matters.

Example: Reorder to Max vs. Days of Supply

Even small planning parameters can radically change outcomes. Consider the Reorder to Max flag or Days of Supply setting—two little checkboxes that can make suggestions either overbuy or underbuy by huge margins. If MRP is acting strange, go check those first before blaming the system.

Pro Tip: Don’t Ignore Your Calendars

One of the most overlooked contributors to inaccurate schedules is a misconfigured resource or plant calendar. MRP uses calendars to calculate when work can be done—not just when it should be done. If the calendar is missing holidays or has old shift data, your job dates will drift and throw everything else off.

Final Thought

MRP is incredibly powerful, but it’s only as smart as the data you feed it. Clean input = good suggestions. Bad data = chaos.

Before you question the MRP engine, take a look at the foundation it’s built on. Nine times out of ten, that’s where the fix needs to start.