Hi everyone! Long time no see. I have a new job as an app analyst for cirrus aircraft. They are going from Avante to Kinetic. I was wondering if anyone has a diagram that they presented that has the manufacturing process all mapped out and how epicor is used.

Many of you know me as the Kinetic Consultant (ERP10 consultant, Vantage Consultant) and now as the Kinetic Product Manager… but before that I lived the life of Avante Consultant and Avante Tech Support manager/lead… still before that I was a customer who purchased and Implemented Avante.

Many years ago, I gave several classes to Avante customers at Insights around the difference between the two. Many of the differences are along the lines of terminology. Vantage/ERP10/Kinetic inherited many of the rich features that Avante has. Cycle Counting, Serial Tracking, Unit Of Measures, the new “Dynamic Time Fence” feature, and the upcoming (SAFE HARBOR) Sales Order Deliver plan features all came from Avante.

Below is a document that describes the differences in both Process/Capability and in terminologies between Kinetic 2025.1 and Avanté. The origin of this document was comparing Avante with Vantage 8. It has been updated with a few of the new features that Kinetic also possesses. This is not meant to be a 100 percent complete “net change” or “gap analysis”, but is intended to be a launching point for further analysis.

Most of these comparisons are done to the current releases of Avanté & Kinetic… any future version differences are highlighted where known.

| Issue Type/Category | Avanté 9.4.6 | Kinetic |

|---|---|---|

| Terminology | Work Order | Job |

| Terminology | Job (actually a sales order turns into a Job that tracks all associated work orders. One work order per deliverable MTO/CTO.) there is only one JOB per Sales order | Vantage creates a separate Job for each deliverable on a sales order that is MTO/CTO. All the jobs can be linked back to the sales order using the sales order number |

| Terminology | GLG Code (General Ledger Group Code) Contains all Inventory and WIP accounts for a particular product group. These are assigned to parts, and can be assigned to a part at the warehouse level as well | Part Class. NOTE: that part classes do NOT contain the WIP account. Only one part class can be assigned to a PART. Cannot set a different Part class at the Item/Warehouse. |

| Terminology | SPC Code (Sales Posting Code): Contains the Sales, and Cost of sales accounts | Product Group: This contains the sales, cost of sales and WIP accounts for a group of products. Set at the PART level. But Product Group can be adjusted at the sales order level. |

| Flexibility | Work Center – a place where work is done. Set an hourly rate, and number of available hours. | Resource Group: a group of like resources (machines, people). These can be used for scheduling. Hourly rates for usage are stored here. We also have “Capabilities” which is a group of resources that have the same capability but possibly different efficiency levels. |

| Flexibility | GLG/SPC Code support Wildcards in COMPANY and DIV fields. If wildcarding is not wanted, user can force a specific GL account. | Division and Department have implied wildcards. If GL account exists – Wildcarding automatic. No option to turn off. |

| Flexibility | Only 1 active Engineering revision. | Many active revisions. Can sell any revision. Can Make any revision. Inventory can now be stored at the part/revision level, and MRP can plan by revision. |

| Number of active Engineering/Production Revisions | As of 9.5 – different revision per plant | Each plant (Now called “SITE” in Kinetic) can have a different default ALTERNATE METHOD, but there is only one active revision per company. You can have as many alternate methods as desired tied to a revision. If you make the same part in multiple sites, you must have a different alternate method per site. |

| Routings & Resources controlled by Revision? | Revisions control Bill Of Material only. The routing is not part of the revision control. | Revisions control Bill of Material (BOM) and Bill of Operations (BOO, aka Routing), and assigned Resource Groups/resources. The BOM and BOO are called the“Method of Manufacturing” (MOM for short) |

| Steps to create new revision: | 1. create ECO, 2) create Revision. 3) modify BOM | 1. Define Revision, 2) Create ECO. 3) Check out revision, 4) Copy “Method” into new revision. 5) Check in revision and Approve Revision. 6) Un-approve old revision (if desired). Note that steps 1-4 above are done in one step with newer “mass checkout” option in the engineering workbench. |

| Product Costing | Cost sets can be assigned at the warehouse level. | Cost sets determined at the SITE level. Each site can have a different cost but all warehouses in a site have same cost values. |

| Product Cost Method (Average/Std/Last | Costing method is determined at the Warehouse level | Costing default can be set at the SITE.. Each part number can override the plant… Then again at the Part/Site screen.. Costing methods are Lot, Fifo, LotFifo, Std and Last cost. Each can be determined at the partSite level. |

| Labor Rates | Labor rates determined by the Labor rate table | Labor rates determined by Resource group and/or Resource for calculating the standard/estimated cost. The actual Charge rate for labor is based on the labor rate associated with the workforce ID who clocks into he job. |

| Labor Burden | Labor burden determined by Burden rate table | Burden rates determined by Resource group and/or Resource. |

| Material Burden | MTL Burden Controlled by the cost table entry | Mtl Burden entered at the PART definition. All SITES receive the same rate/part |

| Lot Control | If one Warehouse is Actual cost, all parts in all warehouses, in all companies must be under full lot control | Lot control is turned on at the Part Number level. If Lot control is on, then Average Cost functions as “LOT cost” (not actual cost) does in Avanté, as long as single receipts per lot are performed. MRP can honor lot expiration date. |

| Serial Tracking | Can be tracked at lower levels. | Full lower level tracking just like Avante was added to Kinetic |

| Backflushing | Within an operation, Backflushing bins can be specified at the by part/bin. | With AMM, all parts from a “resource” must backflush from the same BIN. Both Labor and Material can be backflushed. Labor can be collected via “Qty Only” transactions or backflushed when subsequent operation is complete. |

| Cycle Counting | Avante’s cycle counting is a robust auditable cycle counting procedure | Kinetic’s cycle counting was designed after and nearly 100% mimics Avante’s cycle counting. One exception is that cycle counting periods do not have to be a month, but can be any period you define. |

| Physical Inventory | Avante’s Physical Inventory process is a different set of programs than the Cycle Counting. | When Kinetic inherited Cycle Counting from Avante, it was decided to use the same apps for Physical. Basically a physical inventory process is a “super cycle count” that counts all parts in one Physical Cycle. |

| Unit Of Measure | UOM is 3 digits, Validated, and Number of digits accuracy is defined. | UOM is validated using UOM Classes |

| Customers | Separate customer number for each shipping address. | Only one customer ID (alpha-numeric) required. Allows multiple shipto and billto addresses to be assigned |

| Customers | If billto addresss is different, must have new customer number | Billto address embedded into customer information, but you can also point to a different customer id for the billto |

| Customers | Sales orders can override billing address | Alternate Billing address numbers can be chosen in the sales order, if the customer is approved to be an alternate billto for the sellto customer on the sales order. |

| Suppliers | Supplier address is single address | Supplier can have “main” address, + multiple “purchase points” attached. Electronic payment file created for bank when paying checks… built in functionality in Vendor file definition. |

| Phantom Costing | Phantom routing ignored | Routings are exploded in routing for both costing AND Scheduling/work in a job. |

| Purchase Parts with BOM | Costing ignored on Purchase parts | Purchase parts BOM used to recost part. (workaround.. create a blank alternate bom for Site) |

| Customer pay with Credit card | Add-on extension | Built in functionality… all fields are setup in base code. Interfaces with Paypal Pro (verisign). |

Wow @timshuwy, that brings back memories from my Avante to Vantage conversion! Also, amazed you still have that. It’s spot on.

Also add it’s a little easier to customize Kinetic ![]()

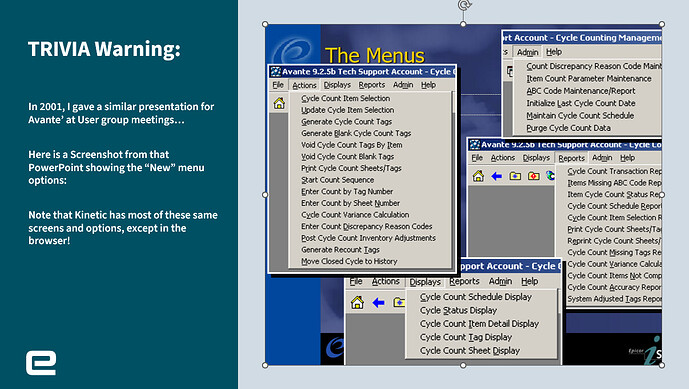

My computer is a storehouse of history… I have powerpoints from my very first Insights and User groups I attended for Avante since 2000. My Webinar on Cycle Counting that I gave earlier this week litterally had a screenshot of a slide from 2001 when I did a similar training on the “New” cycle counting that we were adding to Avante. The cycle counting that we have in Kinetic mirrors much of what we did. In fact the same programmer who wrote cycle counting in Avante, did the design for Kinetic.

For those who have NOT seen the Cycle Count Webinar… here is the link to what I did earlier this week. It is FREE for all who want to learn more: Back To Basics: Cycle Counting and Physical Inventory

I have finally dug into Avante. I can see the similarities if I squint really hard. I think will be a great breath of fresh air for the company I am at now. I have also noticed that the number of modules from my old company to this one are very different. We went with Epicor Enterprise Cloud Services so maybe we have all the modules included. Not sure, but very excited to get this stood up soon and get configuring. Thank you for the terminology list as well. I think that will help me get users more on board with the changes that are coming. It is pretty impressive that you still have all this information readily available for software from what looks like XP. ![]()

hahah.. you will find that I am a wealth of useless (and sometimes useful) trivia.

My best advise… after doing this for years is:

- dont assume anything. Avante and Kinetic are two different products and while things might be named the same, and some things are nearly exactly the same (serialization, Cycle Counting), many things have significant enhancements over Avante (Method of Manufacuting revisions include both BOM and Routing (Bill of Operations).

- Education is key… take all the education you can get. learn the core processes. dont assume you need to customize to make it work. we have many companies who run most of the software out of the box.

- If you truly need customizations (and most do), then use UD Fields, UD Tables, UserCode table, BPMs, BAQs, Dashboards to do this.

Luckily, I came from a company that was moving from ERP10 to Kinetic. So, I am familiar with that part. Avante is the foreign part for me. My previous place had customizations, so I am not worried about making those if needed. Thank you Tim!

I remember answering questions from Cirrus way back when I was in Tech Support (Before 2006). LIke I said, I have a lot of trivia.

Small world, I tried to get a job with Cirrus Aircraft in a past life when I lived in Grand Forks ND. They basically ignored my applications though. lol.

Sorry to hear that. Cirrus was the only place that even called me back to give me an interview. LinkedIn is a dumpster fire of fake job postings and hard to find the real ones.