LynnDavid

October 15, 2019, 4:21pm

1

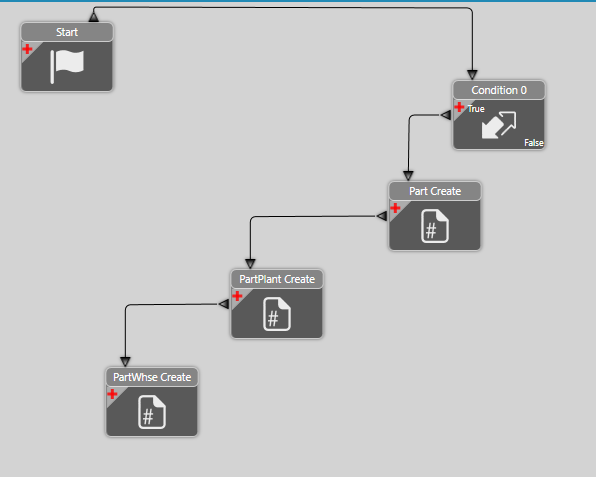

I have a Method Directive enabled on CreateOrder for Quotes that is creating new parts when a certain radio button is marked to “Yes”. It is a Post Process and there are 3 execute custom code. 1st one creates Part record, 2nd one created PartPlant record and 3rd one creates PartWhse. The issue is the PartWhse is running before the PartPlant record and cannot get it to go last.

Any suggestions would be great. I was trying to use callContextBpmData to try and have it go in order but not working.

It’s likely you don’t have the sequence set correctly. They run in numerical order.

LynnDavid

October 15, 2019, 5:22pm

3

They are all inside one Directive. It does not follow if separate even using the Order No for the directive to start at different times.

I suppose it depends on what the code is doing inside.

LynnDavid

October 15, 2019, 5:49pm

5

Part Create code:

foreach (var QuoteDtl_iterator in (from QuoteDtl_Row in Db.QuoteDtl

{

if (QuoteDtlRow != null)

{

Part newpart = new Part();

Db.Part.Insert(newpart);

newpart.Company = Session.CompanyID;

newpart.PartNum = QuoteDtlRow.PartNum;

newpart.PartDescription = QuoteDtlRow.LineDesc;

newpart.TypeCode = QuoteDtlRow.TypeCode_c;

newpart.ProdCode = QuoteDtlRow.ProdCode;

newpart.RefCategory = QuoteDtlRow.RefCat_c;

newpart.Print_c = QuoteDtlRow.Print_c;

newpart.Material_c = QuoteDtlRow.Material_c;

newpart.Diameter_c = QuoteDtlRow.Diameter_c;

newpart.Lth_c = QuoteDtlRow.Lth_c;

newpart.Wdth_c = QuoteDtlRow.Wdth_c;

newpart.CenterThick_c = QuoteDtlRow.CenterThick_c;

newpart.Thickness_c = QuoteDtlRow.Thickness_c;

newpart.EdgeThick_c = QuoteDtlRow.EdgeThick_c;

newpart.CSM_c = QuoteDtlRow.CSM_c;

newpart.Chips_c = QuoteDtlRow.Chips_c;

newpart.Edges_c = QuoteDtlRow.Edges_c;

newpart.Chamfers_c = QuoteDtlRow.Chamfers_c;

newpart.Coating_c = QuoteDtlRow.Coating_c;

newpart.Centration_c = QuoteDtlRow.Centration_c;

newpart.Wedge_c = QuoteDtlRow.Wedge_c;

newpart.TIR_c = QuoteDtlRow.TIR_c;

newpart.TrnWve_c = QuoteDtlRow.TrnWve_c;

newpart.Parallel_c = QuoteDtlRow.Parallel_c;

newpart.DocReq_c = QuoteDtlRow.DocReq_c;

newpart.PackReq_c = QuoteDtlRow.PackReq_c;

newpart.MatCerts_c = QuoteDtlRow.MatCerts_c;

newpart.SurfaceQual_c = QuoteDtlRow.SurfaceQual_c;

newpart.SurfaceAcc_c = QuoteDtlRow.SurfaceAcc_c;

newpart.SurfaceRough_c = QuoteDtlRow.SurfaceRough_c;

newpart.ClearApert_c = QuoteDtlRow.ClearApert_c;

newpart.Radius_c = QuoteDtlRow.Radius_c;

newpart.Spec1R2_c = QuoteDtlRow.Spec1R2_c;

newpart.SurfQual2_c = QuoteDtlRow.SurfQual2_c;

newpart.SurfAcc2_c = QuoteDtlRow.SurfAcc2_c;

newpart.SurfRough2_c = QuoteDtlRow.SurfRough2_c;

newpart.ClearApert2_c = QuoteDtlRow.ClearApert2_c;

newpart.Spec2R1_c = QuoteDtlRow.Spec2R1_c;

newpart.Spec2R2_c = QuoteDtlRow.Spec2R2_c;

newpart.CS1_c = QuoteDtlRow.CS1_c;

newpart.CS2_c = QuoteDtlRow.CS2_c;

newpart.CS3_c = QuoteDtlRow.CS3_c;

callContextBpmData.Number07 = QuoteDtlRow.QuoteNum;

this.PublishInfoMessage("QuoteDtl.PartNum: " + QuoteDtlRow.PartNum + " " + " QuoteDtl.QuoteNum: " + QuoteDtlRow.QuoteNum + " newpart.PartNum: " + newpart.PartNum , Ice.Common.BusinessObjectMessageType.Information, Ice.Bpm.InfoMessageDisplayMode.Individual, "QuoteDtl-Post1", "CreateOrder");

}

}

LynnDavid

October 15, 2019, 5:50pm

6

PartPlant Create code:

using (var txScope = IceContext.CreateDefaultTransactionScope())

if (QuoteDtlRow != null)

{

PartPlant newpartplant = new PartPlant();

Db.PartPlant.Insert(newpartplant);

newpartplant.Company = Session.CompanyID;

newpartplant.Plant = "MfgSys";

newpartplant.PartNum = QuoteDtlRow.PartNum;

newpartplant.PrimWhse = "Main";

newpartplant.SourceType = QuoteDtlRow.TypeCode_c;

callContextBpmData.Character10 = newpartplant.PartNum;

//callContextBpmData.Number07 = QuoteDtlRow.QuoteNum;

this.PublishInfoMessage("QuoteDtl.QuoteNum: " + QuoteDtlRow.QuoteNum.ToString() + " QuoteDtl.PartNum: " + QuoteDtlRow.PartNum + " newpartplant.Part: " + newpartplant.PartNum + " newpartplant.Plant: " + newpartplant.Plant + " BPMData.C10: " + callContextBpmData.Character10, Ice.Common.BusinessObjectMessageType.Information, Ice.Bpm.InfoMessageDisplayMode.Individual, "Quote-Post2", "CreateOrder-Post");

}

}

Db.Validate();

txScope.Complete();

}

LynnDavid

October 15, 2019, 5:51pm

7

PartWhse Create Code:

this.PublishInfoMessage("CCBpmData.C10: " + callContextBpmData.Character10, Ice.Common.BusinessObjectMessageType.Information, Ice.Bpm.InfoMessageDisplayMode.Individual, "QuoteDtl-Post2", "CreateOrder");

if (PartWhse != null)

{

PartWhse newpartwhse = new PartWhse();

Db.PartWhse.Insert(newpartwhse);

newpartwhse.Company = Session.CompanyID;

newpartwhse.PartNum = callContextBpmData.Character10;

newpartwhse.WarehouseCode = "Main";

this.PublishInfoMessage("newpartwhse.PartNum: " + newpartwhse.PartNum + " newpartwhse.WarehouseCode: " + newpartwhse.WarehouseCode, Ice.Common.BusinessObjectMessageType.Information, Ice.Bpm.InfoMessageDisplayMode.Individual, "QuoteDtl-Post3", "CreateOrder");

}

Db.Validate();

txScope.Complete();

}

LynnDavid

October 15, 2019, 5:51pm

8

I attached the code for all 3 custom code.

Thanks. I would offer that you should use the Business Object Method instead of the “Insert”.

LynnDavid

October 15, 2019, 5:59pm

10

i tried adding Erp.Contract.BO.Part to directive, but i get the following error:

There is at least one compilation error.

I wish there was a more viable solution for these. Can you use a CallContext and a Data Directive with Code and a BO?

LynnDavid

October 15, 2019, 6:12pm

12

Unfortunately if I set a CallContext in Method Directive, the Data Directive does not see it or find it.

Really?!? That’s a surprise. I guess I don’t recall if I’ve used that before.

LynnDavid

October 15, 2019, 6:17pm

14

i just tried it again and the QuoteDtl Standard Directive did pick up on the CallContext.

Perfect. That should work then.

1 Like

LynnDavid

October 15, 2019, 6:18pm

16

But the Standard Directive did not start when call the Create Order. Only when changed Quote Detail.

LynnDavid

October 15, 2019, 6:23pm

17

nope. I need the Data Directive called or started when CreateOrder is launched.

LynnDavid

October 15, 2019, 6:25pm

18

The orderdtl Standard Directive found the callContext record and I was able to add the Erp.Contracts.BO.Part to the References section. But the standard does not have the option for “Invoke BO Method”.

jgiese.wci

October 15, 2019, 6:27pm

19

LynnDavid

October 15, 2019, 6:32pm

20

When I add that code in I get an error: "The type or namespace name ‘Internal’ does not exist in the namespace ‘Erp’ (Are you missing an assembly reference?)