Not sure. How to check that?

Fields on the JobHeader. job tracker or entry should show it.

Thank you. I’ve checked and confirmed that there is no lock. The two jobs were created in the Main site. One of the jobs, which has a quantity of 20, was supposed to be created in the RAK site. I presume this is why the quantity of 10 is not being reduced in the existing job.

Sorry for the parallel thread but I have been staring at this off and on for 3 days.

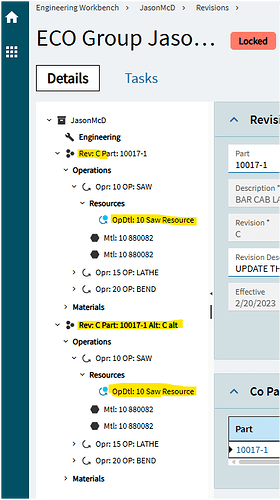

I think I see it now:

- Revisions are site-specific (as are alt methods)

- Operations are not site-specific

- Resource Groups are site-specific

So there is still the major irritation of needing to make alt methods for a second site - down to the last subassembly etc.

BUT, I did a test with this (adding both sites’ resource groups to the operation):

- I made a new alt method in Engineering Workbench

- It copies the BOM and BOO (operations)

- It looks like it copies the resources, too - but…

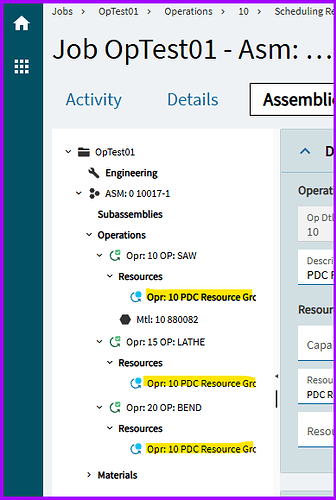

- When I made a job in site B and ran “Get Details,” it worked! It grabbed the resource group for site B.

So this does mitigate one frustration point, which is Engineering Workbench. Today we replace all operations in the alt with operations for that other site. But with the proper setup, it isn’t necessary - the operations can stay.

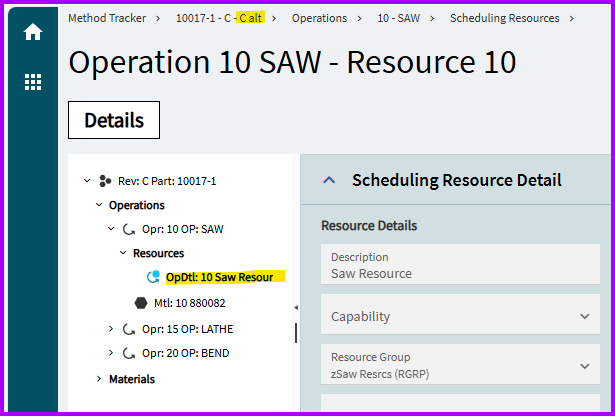

Odd that it still stores the resource group (PartOpDtl table) from site A in the alt method for site B:

But again, you still need an alt method, and then you have to specify that alt in PartPlant (Part >Sites > Primary Alternate Method) and update that at every revision.

But I sure learned something!

i found this odd too and even put in a ticket to epicor. when you create the Alt method it looks like the resources are still from the original site. we were on 10.2.700 when i was playing with it and i have tried it since upgrading to 2024.2.

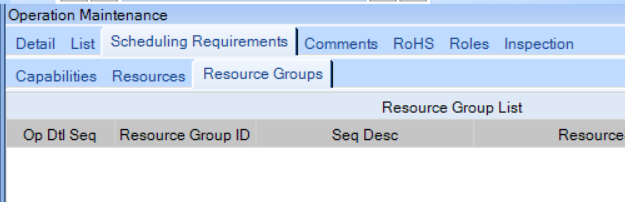

In Operation setup you select a Resource Group, isn’t that what would be causing it to pull the resource from Site A? If you have set a Resource Group for the operation that is.

We have the same operation across multiple plants but we’ve made separate operations for each plant, this was so we could assign the plant specific resource group to each operation so i didn’t have to change it in Engineering WB in every site.

I can’t remember for sure, but I vaguely remember running into our own MRP issues when we were using alt methods. We switched to having different revisions for each plant rather than having a main rev and alt methods. Is there any reason alt methods are the route here?

Oof you are surely asking the wrong person to defend this. I do not love alt methods (understatement!). But I also do not agree that 2 identical but separate revisions are the answer.

What does your company do? Engineering releases revision D (somehow outside of Kinetic if it’s like it is where I work) and then a Kinetic user creates rev D1 for the main site and D2 for another site and so on?

To defend alt methods:

- I made a BAQ long ago that flags more than one approved (main) revision per part (assuming this is breaking protocol). It helps us ensure that someone does not have old revs still approved.

- Likewise, if you use alt methods, once rev D (main) is unapproved, it unapproves D/Alt1 and D/Alt2, etc. They flock together.

I get it, a trouble with alts is setting that stupid Primary Alternate Method on PartPlant (Sites section of Part Entry). It’s really annoying to have another field to keep up with when I never wanted to be bothered with alt methods in the first place. Two distinct revs solves that.

Both ways have majorly annoying flaws that basically only lead to ruin because a human is not keeping up with dotting I’s in Kinetic.

[Rant ahead]

I just don’t get why we are (all) forced to do this - either option.

If we have two identical sites (they both just weld stuff together) using identical parts in the same sequence, why do we have to make two revs (alt or otherwise)?

To me an “alternate” method is for a time when you might have different materials or procedures to make the same thing. Use 1/4" plate steel on the burn table instead of sawing 1/4" bar stock to length (or vice versa). Same end product, but two (rather different) ways to make it.

We make concrete products, our revisions do not change often or ever in some cases. We have different concrete mix part numbers for each plant to be used in the BOM. So i create a revision for each plant that is going to produce the product, we prefix based on site name so S0010 and C0010. In my case they’re not identical as the BOM is different in each plant, packaging materials can be different, the mix will be different. Perhaps that’s the reason this works well for us.

Sometimes a change happens to 1 site BOM but doesn’t need to happen in another so i don’t need or want all revs to unapprove when making that change. I also only keep 1 approved rev per plant.

When i was first starting with BAQs it was always a pain getting duplicates with alt methods, that may not be an issue anymore but not having to worry about it, and not having to keep up with the Primary Alt Method is nice too.

You are correct that this is ONE of the reasons for Alternate methods, but alternate methods are also requred if you make something in two different sites. WHY? Well, the two sites have two different resources, and those resources COULD have different run rates, and MIGHT be different costs. You cost tables might be different in the sites. Kinetic is designed to handle all of these variances between two sites.

All that said, you do NOT want to create two different REVISIONS for the two sites. only create Alternate METHODS for each additional site.

site 1: Alternate method can be blank

Site 2: Alternate method S2

Site 3: Alternate method S3

Note that when you check out the REVISION, all three alternate methods are also checked out to the Engineering Work Bench. If you add a material to the blank alternate, it will also add it to the other two alternates as well, making changes a little easier.

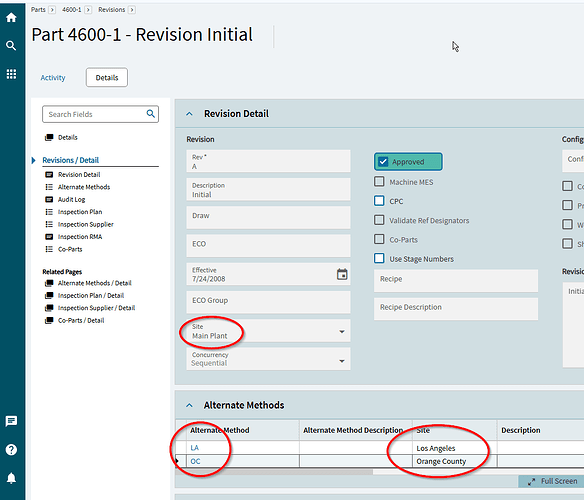

Here is a screenshot showing how each revision, and each alternate method is assigned to a specific site.

Right, and I respect the option for that flexibility.

And the fact that you can do this with operations and resources makes a ton of sense.

But my beef is that this complexity has no opt-out feature. There’s no way to make a generic rev (no site specified).

What I run into is that we have multi-level indented BOMs that are shared across 2 or 3 sites. Sometimes people get the alt-method concept well enough to make an alt-method for the top level part.

But then MRP runs and the jobs cannot be created because some subassembly does not have an alt method (that is defined as the primary alt in PartPlant, with proper resources, etc.).

And MRP doesn’t bother to alert you that it could not create that job.

I try to make BAQs to hunt down these rules, that every pull-as-assembly component of an alt method has to also have an alt for that site and so on, but it’s a lot.

The resource thing is workable. A pain, but reasonable.

But the revisions themselves - those are the choke point.

It’s a classic example of us serving the system far more than any benefit we get out of it. We slave away at dotted I’s and crossed T’s just to get base functionality to work.

I don’t mean that all of Kinetic is like that. But this sure is.

i do agree that it would really be nice if there was a way to make a revision be generic. In fact, one could argue that PHANTOM BOMs could and should be generic without any site tied to them, especially if there is no operation tied to the phantom.

But you are also pointing out that there is no way to easily validate your BOM for a specific site. This might also be a great place to advertise Epicor ideas, ![]() as having a BOM validator that would tell you any potential problems might be good. (Example errors: Lower Level BOM still checked out, Lower Level BOM not for correct site, etc).

as having a BOM validator that would tell you any potential problems might be good. (Example errors: Lower Level BOM still checked out, Lower Level BOM not for correct site, etc).

One additional note: if MRP cannot generate a job, the system DOES leave the part in the planning workbench for parts that still need jobs. This should be a place that people regularly check.

No shortage of things I am still learning after almost 9 years.

me too… only i have 20+ years on kinetic, and still learning.

If you have never used the planning workbench, you should check it out… you can create a new sales order for a new part that doesnt have a BOM, and it imediately shows in the planning workbench. when MRP runs, it will still show until it can successfully build a job.

It even tells you whats wrong with your method sometimes. If you have a subassembly without a good method it will tell you what part is preventing a job from being created.

its a very useful tool.