What is the difference between Plan as assembly and pull as assembly?

From the data dictionary for PartMtl

PlanAsAsm : This is relevant for assemblies (Part.Method = Yes).

Indicates if the sub-assemby can be spawned off to a different job.

Can be true only if PullAsAsm = true.

PullAsAsm: This is relevant for assemblies (Part.Method = Yes).

Indicates that if this assembly should be pulled from stock or

manufactured as part of the job it is pulled into.

If PullAsAsm = No only the assembly record will be pulled into the job/quote (as a material),

the related material and operations will not be pulled over.

e.g. SubJobs and SubAsms

In the Engineering Workbench, Plan as Assembly allows you to work with a manufactured part’s BOM and Method (in the Engineering Workbench), where Pull as Assembly determines if it will pull into jobs as a subassembly or, if unchecked, as a material.

Hi @bordway , @wayne.welsch,

Thanks for the information. Any rule set need to apply for the plan as assembly material ?

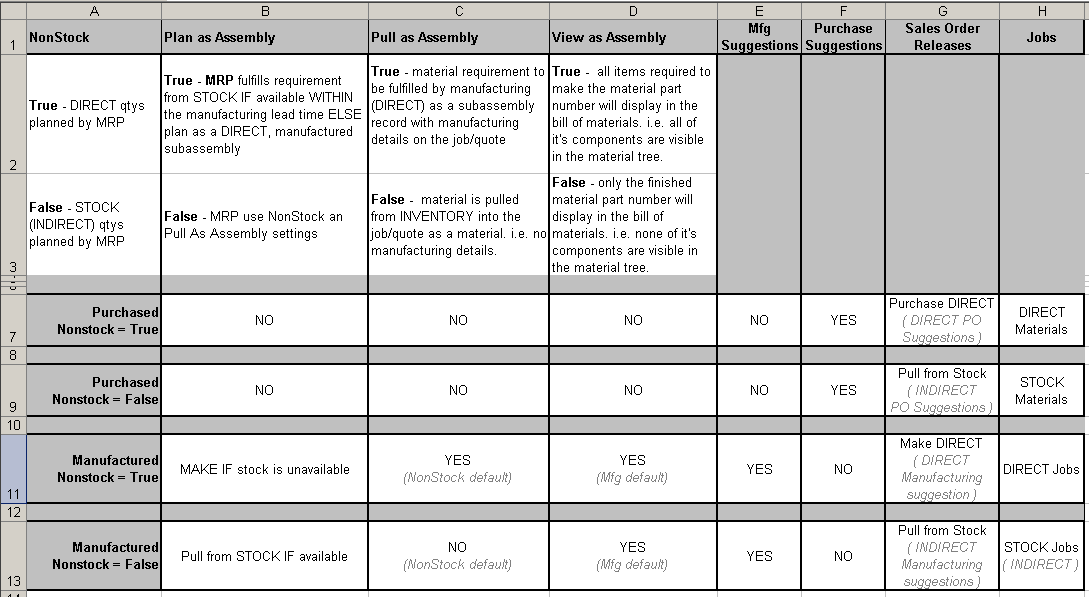

They can be related to the NonStock flag.

Here is a screenshot of an old spreadsheet, it’s pretty old but I think it’s still valid.

Should get you in the ballpark at least.

When I was starting out, I used a Test system first. Where I made some stock/nonstart parts and simple methods for each type, then ran MRP. Note that the overall build time can vary A LOT depending on how part masters and methods are setup. Lead times, MFG Lead TIme, Phantoms too…