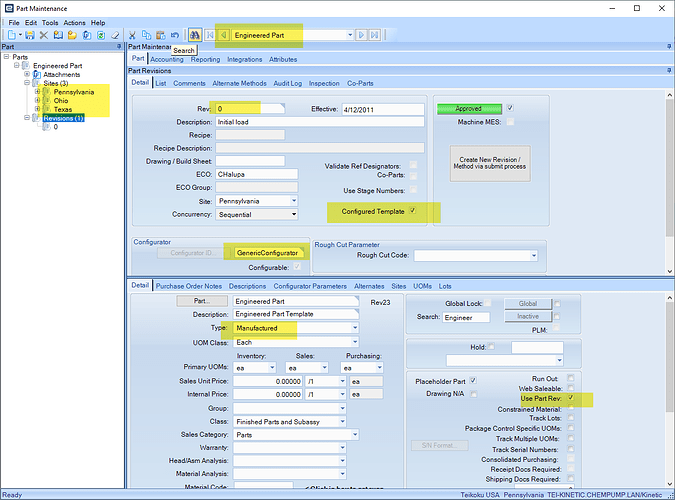

We are trying to automate more tasks, and streamline a bit.

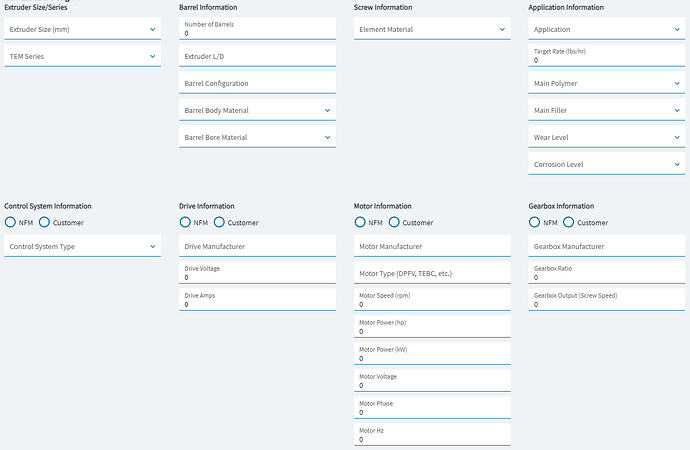

What we want to do at the basic concept level, is have our sales team fill out a form with all the relevant data for creating a part, and then have our engineering team finish it out.

Notes:

- We aren’t licensed for configurators, and I don’t know anything about them, but if that’s the best option, don’t hold back.

- No, we do not want to use Part Entry (For the sales people)

- Yes, we want to actually create the part, not just enter data.

How do y’all think I should approach this? Y’all know I can code, so keep that in mind with your recommendations if you feel that is relevant.

Thanks in advance.