I too am having issues with Global Scheduling. I am running the Calculate Global Scheduling Order then Global Scheduling. However, I am finding large gaps between operations. If I manually reschedule a Job from the start date the gaps, then are no longer an issue. Is there anyone out there who successfully uses Global Scheduling?

What is your default scheduling direction on the site?

We see a similar effect. We have many jobs, for a handful of different mfg’d parts, that all use the same operation (machine and operators).

Depending on the global scheduling order calculation, and the backwards/finite global scheduling process, we see other jobs (higher priority/lower scheduling order value) requiring the operation in order to fulfill the ShipBy requirement, and the other jobs (lower priority/higher scheduling order value) getting split up like you are describing.

backward scheduling

That would explain it then. Backward scheduling looks at the revision method time to manufacture and the due date of the demand. It will then start at the demand due date and schedule each operation until it arrives at a start date.

If you are trying to “fill up the shop”, you will need to switch to forward scheduling and make sure you set the start date so the engine knows when you want to start the job.

We were seeing these as well and opened a support ticket for it. We were told it was related to gaps in our production calendar. The production calendar was filled in with working hours 8-12 and then 1-4. Support suggested removing the lunch hour gap.

We did that but still were seeing gaps. Next up was to split our job quantities so the operations took less time and could be dropped in (e.g., if the total operation is over 100 hours, scheduling keeps looping to find a spot to put it). At that point other things came up demanding attention and we haven’t gone back to trying to resolve it yet. Will be monitoring this to see if you are able to find a solution ![]()

Jenn

That should not matter. The schedule will add operations anywhere there is room. I even got that confirmed from Stephon Gregory at Insights and have performed some testing to confirm it.

It would be helpful to understand the logic behind Global Scheduling to make trouble shooting easier. The information on the subject is pretty sketchy. So many questions on how Global Scheduling is designed to work and so few answers.

It just takes a lot of testing and playing with settings. If it was easy, master schedulers would not be in demand.

There is a lot of settings for it that all interact. If you have specific questions, fire away.

what you are describing is often the symptom of too many jobs wanting a common resource.If you are doing finite scheduling, the system is looking for an open time block which your operation will fit into. For example, if your job has 20 hours of work to be scheduled, the system starts to scan the schedule to look for 20 hours of time on a resource. it will keep looking (no matter whether FORWARD or BACKWARD scheduling), until it finds a block of time, which it then reserves. so if you have three operations, each on a different resource, the system may be in a situation where it finds op 10 can be done in June, op 20 cant be worked on until August, and op 30 cannot find time until october.

Story time… back when I was in tech support (22 years ago), a customer called and asked why their job was scheduled two years out.. upon looking at the job, it was something like 80 hours of work… we scanned their resources, and the first 80 hour block of open time was not for 2 years… everything else was chopped up into smaller units. The answer was to break this into smaller jobs, or, in this case, i think we simply overrode the schedule and processed it. (End of story time)

OK… onto the solution options:

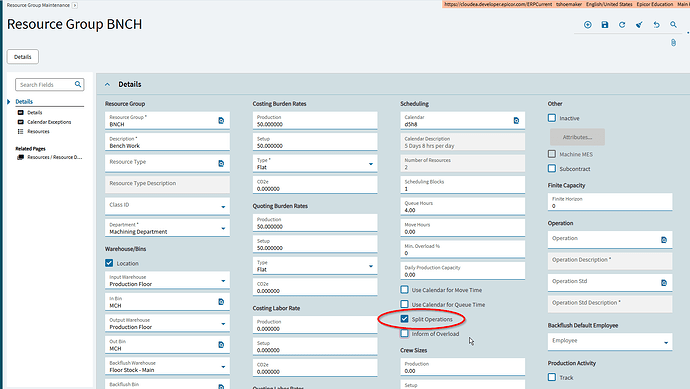

- Allow split operations (See Illustration 1 below). This allows the system to split up the operations into differing timeslots. so it might schedule some of op 10 on Monday and the balance on Thursday, then the following Wednesday. It might also change resources at each time slot.

- Make smaller jobs. This was already suggested above.. not always applicable, but it is a thought.

- Schedule the job without finite scheduling to see how it schedules. You will probably find that it is scheduled the way you expect it.

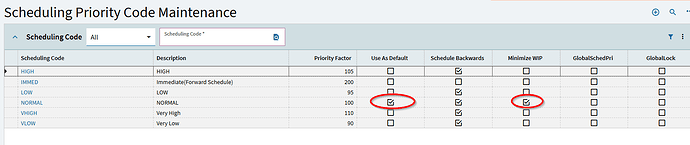

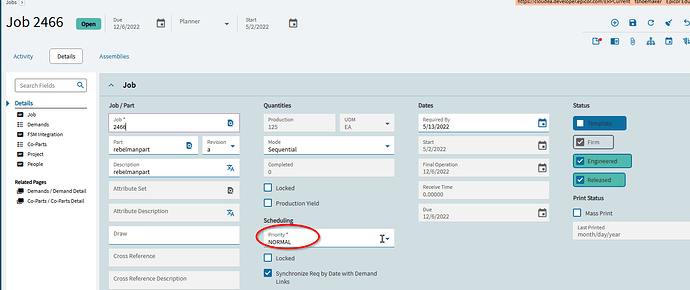

One more thought.. when doing scheduling there is also an option to do what is called “Minimize WIP” on your schedule. it does a two or three pass schedule. For example, if you do a backward schedule and the system finds it cannot start in time, it will then reverse and do a forward schedule from the earliest start. This gives the system what the earliest finish will be. Then it does one more pass with backward scheduling, using the earliest finish, and tightens up the schedule, resetting the start date to be the latest it can be while finishing the earliest it can finish. This will reduce the gaps. TO DO THIS, you need to use the Minimize WIP Setting in the Scheduling Priority Code Maintenance. (see Illustration 2 below). In my case, I set my default “Normal” scheduling to use the minimize WIP scheduling. Then on my job, I have the scheduling set to use this scheduling code (see Illustration 3 below)

(Illustration 1)

(Illustration 2)

(Illustration 3)

Thank you, Tim, we did not have minimize WIP checked in the priority code maintenance! Schedule is looking better!