Looking to make a BAQ/Dashboard for shop supervisors to have a better understanding of what they should be working on.

We are a custom job shop and many of our jobs include sub-assemblies.

Usually the header level assembly (0) has 2 operations (10 &20)- The first operation is tear down mechanical work. The second operation is put it back together mechanical work.

In-between operation 10 and 20, we work on the sub-assemblies. Most of these sub-assemblies can be worked on in sync.

I have gotten pretty far with the previous operation complete but still having trouble with that Asm 0 op 20 showing ready to work before all sub-assemblies are complete.

Any Ideas?

Show us what you have so far. I bet we can find a solution. My first step would be to try out the Priority Dispatch Report to see if that canned report covers what you need.

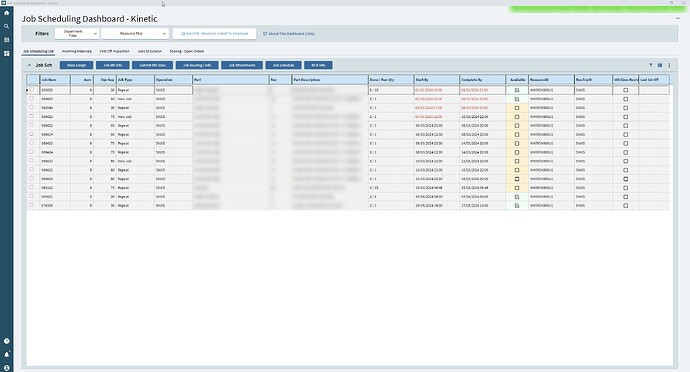

This is what I have so far. It works for 70% of what we need.

There is a calculated material status, previous operation complete, and then a ready to work which looks at both fields and tells the supervisors what they should be working on.

select

[JobOper].[Company] as [JobOper_Company],

[JobOper].[JobNum] as [JobOper_JobNum],

[JobHead].[GenDesc_c] as [JobHead_GenDesc_c],

[JobOper].[AssemblySeq] as [JobOper_AssemblySeq],

[JobOper].[OprSeq] as [JobOper_OprSeq],

[PurchaseDirect].[Calculated_MaterialStatus] as [Calculated_MaterialStatus01],

(Case

When PrevsubOpCmpt = 1 AND MaterialStatus = ‘All Mtl. Received’ then 1

when PrevsubOpCmpt = 1 AND MaterialStatus = ‘No Material Required’ then 1

else 0 end) as [Calculated_ReadyToWork],

((case when (((select distinct top (1)

[JobOper1].[OpComplete] as [JobOper1_OpComplete]

from Erp.JobOper as JobOper1

where (JobOper1.Company = JobOper.Company and JobOper1.JobNum = JobOper.JobNum and JobOper1.AssemblySeq = JobOper.AssemblySeq and JobOper1.OprSeq < JobOper.OprSeq)))) is null then 1 else ((select distinct top (1)

[JobOper1].[OpComplete] as [JobOper1_OpComplete]

from Erp.JobOper as JobOper1

where (JobOper1.Company = JobOper.Company and JobOper1.JobNum = JobOper.JobNum and JobOper1.AssemblySeq = JobOper.AssemblySeq and JobOper1.OprSeq < JobOper.OprSeq))) end)) as [Calculated_PrevSubOpCmpt],

(CASE

WHEN PurchaseDirect.Calculated_MaterialStatus = 1 THEN ‘PO Required’

WHEN PurchaseDirect.Calculated_MaterialStatus = 2 THEN ‘Mtl. On Order’

WHEN PurchaseDirect.Calculated_MaterialStatus = 3 THEN ‘All Mtl. Received’

WHEN PurchaseDirect.Calculated_MaterialStatus = 4 THEN ‘Shortage’

ELSE ‘No Material Required’ END) as [Calculated_MaterialStatus],

[JobHead].[StartDate] as [JobHead_StartDate],

[JobHead].[DueDate] as [JobHead_DueDate],

[JobHead].[ReqDueDate] as [JobHead_ReqDueDate],

(JobHead.Expedited_c) as [Calculated_Expedited],

[Customer].[Name] as [Customer_Name],

[JobOper].[StartDate] as [JobOper_StartDate],

[JobOper].[DueDate] as [JobOper_DueDate],

[JobOpDtl].[ProdStandard] as [JobOpDtl_ProdStandard],

[ResourceTimeUsed].[ResourceGrpID] as [ResourceTimeUsed_ResourceGrpID],

[ResourceGroup].[Description] as [ResourceGroup_Description],

[ResourceTimeUsed].[ResourceID] as [ResourceTimeUsed_ResourceID],

[Resource].[Description] as [Resource_Description],

[ResourceGroup].[JCDept] as [ResourceGroup_JCDept],

[Resource].[ResourceType] as [Resource_ResourceType]

from Erp.JobHead as JobHead

inner join Erp.JobOper as JobOper on

JobHead.Company = JobOper.Company

and JobHead.JobNum = JobOper.JobNum

and ( JobOper.Company = @CurrentCompany and JobOper.OpComplete <> true )

inner join Erp.JobOpDtl as JobOpDtl on

JobOper.Company = JobOpDtl.Company

and JobOper.JobNum = JobOpDtl.JobNum

and JobOper.AssemblySeq = JobOpDtl.AssemblySeq

and JobOper.OprSeq = JobOpDtl.OprSeq

inner join Erp.ResourceTimeUsed as ResourceTimeUsed on

JobOpDtl.Company = ResourceTimeUsed.Company

and JobOpDtl.JobNum = ResourceTimeUsed.JobNum

and JobOpDtl.AssemblySeq = ResourceTimeUsed.AssemblySeq

and JobOpDtl.OprSeq = ResourceTimeUsed.OprSeq

and JobOpDtl.OpDtlSeq = ResourceTimeUsed.OpDtlSeq

inner join Erp.Resource as Resource on

ResourceTimeUsed.Company = Resource.Company

and ResourceTimeUsed.ResourceGrpID = Resource.ResourceGrpID

and ResourceTimeUsed.ResourceID = Resource.ResourceID

and ( Resource.ResourceGrpID = @Resource_Group and Resource.ResourceID = @Resource )

inner join Erp.ResourceGroup as ResourceGroup on

Resource.Company = ResourceGroup.Company

and Resource.ResourceGrpID = ResourceGroup.ResourceGrpID

inner join Erp.JobAsmbl as JobAsmbl on

JobOpDtl.Company = JobAsmbl.Company

and JobOpDtl.JobNum = JobAsmbl.JobNum

and JobOpDtl.AssemblySeq = JobAsmbl.AssemblySeq

inner join Erp.JobProd as JobProd on

JobHead.Company = JobProd.Company

and JobHead.JobNum = JobProd.JobNum

left outer join Erp.OrderHed as OrderHed on

JobProd.Company = OrderHed.Company

and JobProd.OrderNum = OrderHed.OrderNum

left outer join Erp.Customer as Customer on

OrderHed.Company = Customer.Company

and OrderHed.CustNum = Customer.CustNum

left outer join (select

[JobMtl].[Company] as [JobMtl_Company],

[JobMtl].[JobNum] as [JobMtl_JobNum],

(MIN(CASE

WHEN PORel.PONum IS NULL THEN 1

WHEN PORel.OpenRelease = ‘true’ THEN 2

WHEN JobMtl.IssuedComplete = ‘true’ THEN 3

WHEN JobMtl.IssuedComplete = ‘false’ THEN 4

when JobMtl.PartNum = ‘MOBILIZATION’ THEN 5

When JobMtl.PartNum = ‘PERDIEM’ then 5

when JobMtl.PartNum = ‘MACHINERENTAL’ then 5

when JobMtl.PartNum = ‘SUPPLYMATERIAL’ then 5

when JobMtl.PartNum = ‘ENGINEERING’ then 5

ELSE 5 END

)) as [Calculated_MaterialStatus]

from Erp.JobMtl as JobMtl

inner join Erp.PORel as PORel on

JobMtl.Company = PORel.Company

and JobMtl.JobNum = PORel.JobNum

and JobMtl.AssemblySeq = PORel.AssemblySeq

and JobMtl.MtlSeq = PORel.JobSeq

and ( PORel.JobSeqType = ‘M’ )

where (JobMtl.BuyIt = TRUE)

group by [JobMtl].[Company],

[JobMtl].[JobNum]) as PurchaseDirect on

JobHead.Company = PurchaseDirect.JobMtl_Company

and JobHead.JobNum = PurchaseDirect.JobMtl_JobNum

where (JobHead.Company = @CurrentCompany and JobHead.JobClosed = false and JobHead.JobReleased = true and JobHead.JobEngineered = true and JobHead.JobNum = ‘302545-1-1’)

group by [JobOper].[Company],

[JobOper].[JobNum],

[JobHead].[GenDesc_c],

[JobOper].[AssemblySeq],

[JobOper].[OprSeq],

[PurchaseDirect].[Calculated_MaterialStatus],

[JobHead].[StartDate],

[JobHead].[DueDate],

[JobHead].[ReqDueDate],

(JobHead.Expedited_c),

[Customer].[Name],

[JobOper].[StartDate],

[JobOper].[DueDate],

[JobOpDtl].[ProdStandard],

[ResourceTimeUsed].[ResourceGrpID],

[ResourceGroup].[Description],

[ResourceTimeUsed].[ResourceID],

[Resource].[Description],

[ResourceGroup].[JCDept],

[Resource].[ResourceType]

Hopefully this helps in terms of a visualisation, we redeveloped our E10 dashboard when upgrading to Kinetic.

This might be better addressed by changing the way you create your Jobs. Instead of having the tear down on the 0 level, maybe the lowest assembly can have the tear down operation and the 0 level only have the put back together operation. That way you could use the Work Queue to see what needs to be worked on next.

I replicated the Work Queue in a dashboard at my old job. I used a MIN on the assembly table to find the lowest operation that was not complete and marked them with a 0. All other operations were marked with a 1. I could then filter the dashboard for what could currently be worked on and what was “next”.

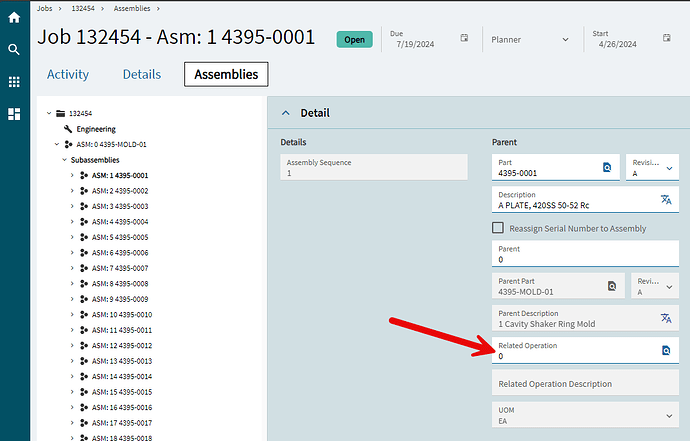

There is a related operation field on the job assembly. Try entering op 20 as the related operation on your assemblies. If the related operation on your assemblies is 0, Epicor’s scheduling logic assumes the subassembly can be started right away, but you want to start with Asm 0 op 10, then work on the subassemblies, then Asm 0 op 20. I believe with the related operation set to 20, Epicor would see that the assemblies need to be finished before op 20 can start. You could see if it reflects that way in the Epicor schedule, and then if so, you could use Work Queue or build that logic into your dashboard.

After reviewing, the work queue is exactly what we need. I think doing a dashboard with the work queue BAQ will work for us.

What is the query would classify an operation to be in the “current” section as opposed to the “all” section.

Running the query I have “all” but looks like current would be exactly what we are needing just not sure how the filters are determining that.

I really like this option as well. Moving forward, we are planning to use this when engineering our jobs.