What we are wanting to do is transition everything in our warehouse over to Bin Numbers and put the parts in the Bin number. The question has been asked, if we do this, will we be able to move the part form one bin to another at will or will this part always be tied to that Bin?

BINS are not typically reserved to any part (or vise versa)… a part can be in as many bins as you want, and a bin can hold as many part numbers as you want.

The Inventory Transfer program lets you move qtys of a part from one bin to another.

And like @timshuwy said, bins aren’t tied to parts. We have some “bins” that are really just shelves on a rack. And can put as many different parts in that “bin” as we want (even if the physically don’t fit).

Give it some thought as to why you’re defining bins. Is it to make it easier to locate the parts? And be careful to not be to granular. A row slot and shelf might be as specific as you want.

Sometimes a bin named “FLOOR” is sufficient. We have one warehouse which is just a holding area for items just passing through. That warehouse has just the one bin, “FLOOR”

In my old factory, we had about 6000 part numbers in the stockroom… the stockroom had about 12 “bays”. Each bay had between 3 and 8 individul Shelves… We gave each shelf a “Bin” number. If I remember, we had somewhere around 200 Bins.

On the shelf (bin), we could store anywhere from one part, to 100s of parts. Some of our materials were 5 pound spools of magnet wire… other parts were little tiny baggies (2x2 inch) filled with 200 little precisely cut pieces of paper, or little tiny pins, or tiny/expensive bobbins. The stock room staff simply went to the bin, and then started searching. They sorted the parts in each bin by Part Number so as to make it easier. Typically a shelf had all common part types… bobbins with bobbins, Wire with Wire, etc.

Use bins as needed for part location. but dont overuse the BIN… it can be a futile exercise in inaccuracy.

Ok, makes sense. The intent here is to identify each “Warehouse” shelving unit with a shelf identifier and then give each column a number or letter and each shelf a number or letter. For instance, stock shelving in the back has 5 row sets, 2 rows per set, and 9 columns per row, with varying amounts of shelf per column. I would simply name the BIN ST1A1 through ST10I10 or something to that nature. I don’t want to over utilize this. Just simply labeling the shelving unit, the row, the column and then the shelf is enough for all intended purposes. The idea is that if we move the part around the plant to a different location it will not need to have to remove the qty from every job, etc in order to move it around. But, is it worth doing It like this, or is their any benefit? Is there anything in Epicor I am missing that could do something like this?

Bins are just an additional key used by E10’s inventory system. The system tracks how many are in each bin, with issues and receipts requiring that a bin be specified.

Some things to think know about “Bins”

- Bins belong to a specific warehouse

- Any part can be received to or issued from any bin

- You can specify a default bin (in each warehouse) for each part. This will be used as the default when receipts or issues are performed. You can almost always override this.

- QOH of a part in a warehouse is the sum of all bins with a qty (positive or negative) for that PartNum. For example: for a given part, I can have 100 in bin A and -10 in bin B, for a QOH of 90.

- A bin can have a negative QOH assigned to it. This happens when a qty of more than the bins QOH are issued from it.

- There are settings you can use to stop part trans from causing a bin to go negative.

- Don’t correct a negative bin Qty with a Qty Adj. To fix negative QOH’s, use a Transfer to move from one bin to another.

- Negative QOH’s are handled properly.

Say there is physically 10 of a part in bin A, 20 more come in and 15 get shipped out right away. Assuming you didn’t set “Stop on negative Qty setting”, if the Shipper processed the packer for 15 before the receipt of the 20 was done, the QOH after the shipment would be -5 (10 -15 shipped).

Then when the receipt is processed the QOH would go to 15 (-5 +20). - Lot cnad S/N controlled parts add a layer. The qty of lot (or individual S/N’s) is tied to the bin.

If bin A has 20 of lot 101, and 15 of lot 102, and bin B has 50 of lot 101, then to issue 30 of lot 101, you’d need either all 50 to come from bin B, or the combo to come from A and B, but no more than 20 from A.

Do you have the Advance material management module?

Yes, we do.

Since you have the AMM, take a look at it’s capapbilities. We don’t have it.

Without it, things like fractional parts can be hard to manage. What I mean by fraction part is something that comes in some “whole” qty (4’ x 8’ sheet, 10’ length of pipe, etc…) but you use fractions of it (1/4 of the sheet 8’ of the 10’ pipe, etc…). the left overs may be useful, but the 10,000 foot view just lumps them all together. All the 2’ leftover pieces of that 10’ pipe are counted. But you couldn’t use them for something that requires a continuous 8’ piece.

AMM has some way of managing this

I would suggest a simple bin numbering system because the more digits in the bin, the harder it is for people to be accurate. Remember that every transaction will need this bin value in the future. A simple Letter/Number is easier to keep in the head.

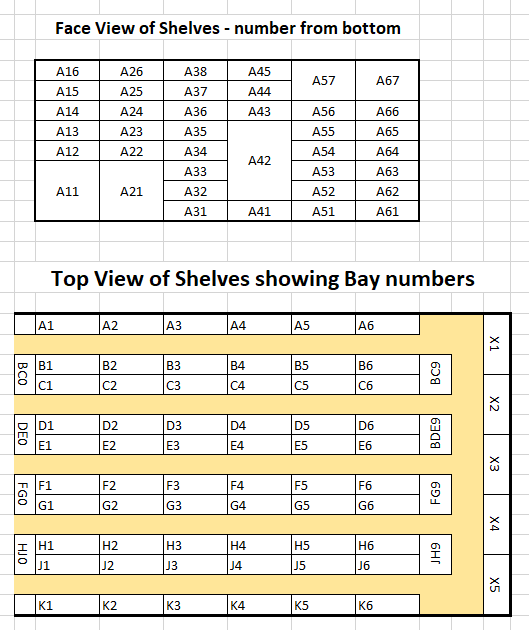

The illustration below is a simplfied system. Each shelf unit is given a value “A1”, “A2”, etc… the “A” is for the row of shelves, the second digit is which unit… THEN, each level would be the 3rd digit, numbering from the bottom… A42 would be the first row, 4th shelf unit, and 2nd level of that shelf. Endcaps like BC0 and BC9 represent the two ends of the B/C row of shelves.

The reason for numbering from the bottom is that all units have a bottom shelf, but not all units have 8 shelves… this illustration tries to show how some shelf bays do not have all the shelves installed.

But, every factory is different, with different needs… some may have “areas” where shelves are… again, I would try to keep that simple and then have the first digit represent the area, and then go with this simple row/bay/level type system.