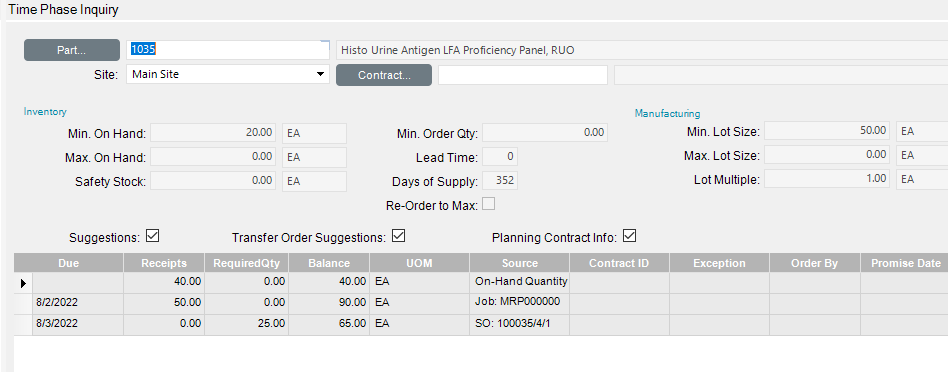

Based on how she phrased her comment I made the assumption they wanted to produce in groups of 50. She’s not below Min + Safety she has 40 and needs 20 that puts her at Min + Safety. Does that count in Epicor as below Safety?

@timshuwy This looks like it worked. I put safety stock to 0 and min on hand to 20. And I eliminated the short planning horizon value that was set to 120. I know have a MRP job for 50 pieces and it will finish before the sales order is due to ship! I will continue to do testing on other parts and add it forecast to this also.

Thank you all!

So… a little bit about Epicor’s Min/Max/Safety settings.

- Epicor is PREDICTIVE… it doesn’t wait till you run out. It takes action before you actually run out. This is why it is not really called a “reorder level” like some systems. If it sees that your order that is two months out will put you below min, it will tell you to order more, even though you are not yet below safety.

- Safety is “special”… if you EVER get below safety, MRP considers this to be catastrophic, and will suggest an IMEDIATE order to fulfill, even if you have no future demands.

- MIN is treated more like a reorder point (except is is predictive) but, if you have a leadtime of 30 days, and if you have the “Allow Consumption of Minimum” setting to TRUE, then the system will not treat it as an emergency, as long as you have a PO or JOB that is scheduled to finish before the leadtime of 30 days.In other words… Minimum of 100, Stock of 100, with a leadtime of 30, and you have a PO to purchase 25 more at 25 days out… if you have a demand that consumes 1 piece, you only have 99 (below min), but since you will fix that within the leadtime, it will not tell you to fix it. IF you did this same thing with Safety stock, it would give an IMEDIATE SUGGESTION for a PO to buy 1 more TODAY, even though you already have a PO.

Reading over this with interest.

We tried MRP a month ago and nothing happened despite making sales orders with finished goods that were marked as MRP parts. We’ll play with the minimum quantities and safety and see what happens.

If you share a screenshot of Time Phase for one of those finished goods, we can try to help with why you did not see what you expected.

Goodday,

I am new to this forum trying to read up on Forecast Entry. My interst is in finding something like a unique identifier for our Purchasing-team, to segregate forecasted stocked parts backed by a customer sales order versus forecast-triggered stocked part demand in their Purchase Order-suggestions. Is there a way, other than the “ORDER BY”-date, to differentiate the demand source? Thank you very much for getting back to me.

Kind regards

Michael Kramer

The source is in PartDtl which makes the suggestions, but I have not found how to link them back except to do a date range for the suggestion to find the PartDtl records that make up the suggestion.

PartDtl SourceFile character X(2) D: Indicates the record type that created this record. JH-JobHead, JA-JobAsmbl, JM-JobMtl, JO-JobOper, PO-PoRels, OR-OrderRels, FC-ForCast

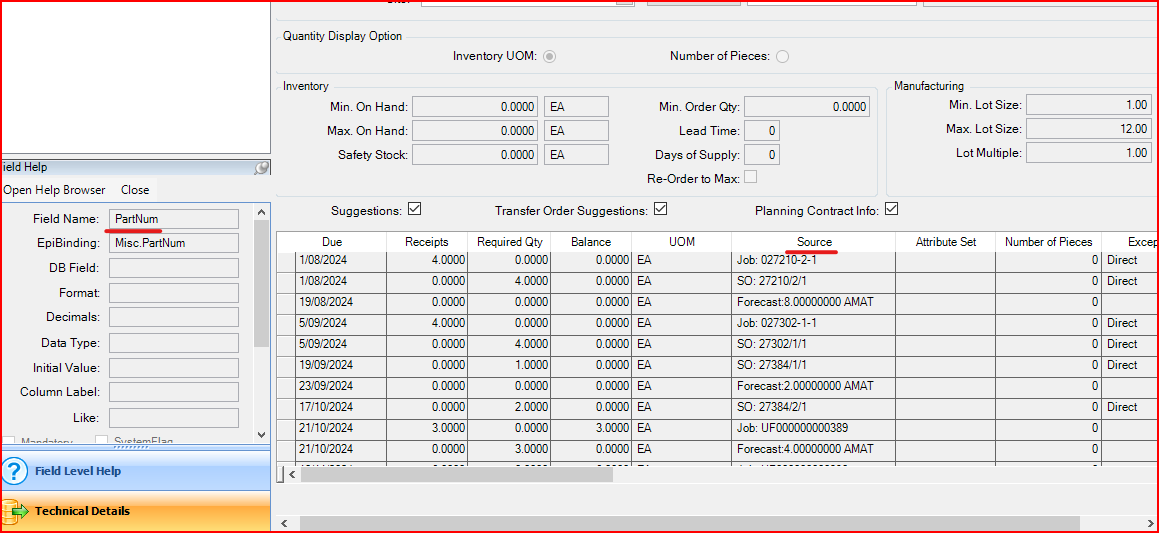

If you look in Time Phase, the “source” column will indicate if the part is required on a Forecast. This only works for top-level parts… all materials needed to build this part will all just have a stock demand (assuming MRP has created the job for the top-level part).

Hi Ernie, I have seen this in TIME PHASE myself and wondered if the column Source (Fieldname: PartNum) can be added to UI PO-suggestions, its seems like a customisation is required for this out of box EPICOR-dashbaord:

Thanks Greg,

I will run this past our IT-department, maybe they are able to link it along the data from UI PO-suggestion dashboard to a customized dashboard they can create for that purpose ¯_(ツ)_/¯

That would most definitely be a customization. The field is from the PartDtl table (as @gpayne mentions above).

Doing it in PO suggestions is really simple in the classic UI.

Add a field to SugPODtl and regen schema. By default or Epimagic those fields show in the material list grid.

In a bpm post processing on POSugg.GetRowsPlant find the requirements from the current suggestion for this PartNum to the next suggestion that are source forecast and set the field. I have 35 fields on just this screen and no custom code to set them, just the bpm.

Thank you so much, I am stoked how quick you guys are responding with great advise ![]()