Old MRP Calculation and NEW Calculations are the same. the results are the same… what is different is the way that we select what needs to be calculated. We were able to perform a pre-filter that eliminated any parts from the MRP Calculations if they didn’t need to be analyzed… basically a pre-analyzer. as a result, MRP has far less to do.

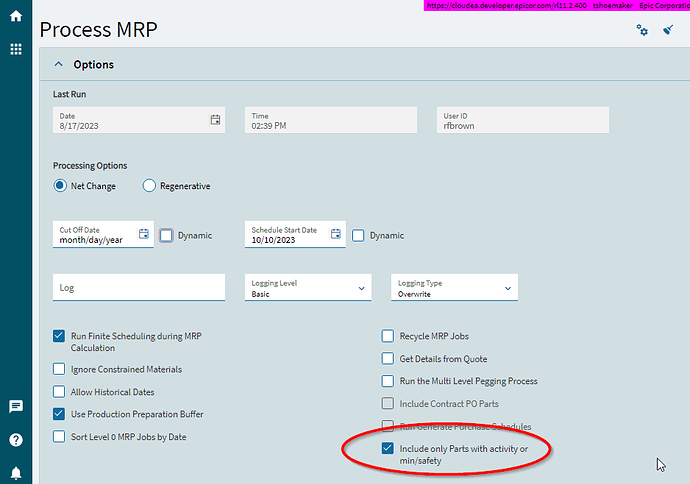

This new feature must be turned on… it is a “sticky” switch (if you turn it on, it stays on… turn it off, it stays off).

The switch describes what it does… it only includes parts that have activity (Demand orders or supply orders) or have Min/Safety quantity set… In other words, if the part has no safety, no min, no orders, no demands, then MRP doesn’t need to look at it. if this switch is turned on, then MRP will still look at the part, and that is not as efficient.

3 Likes