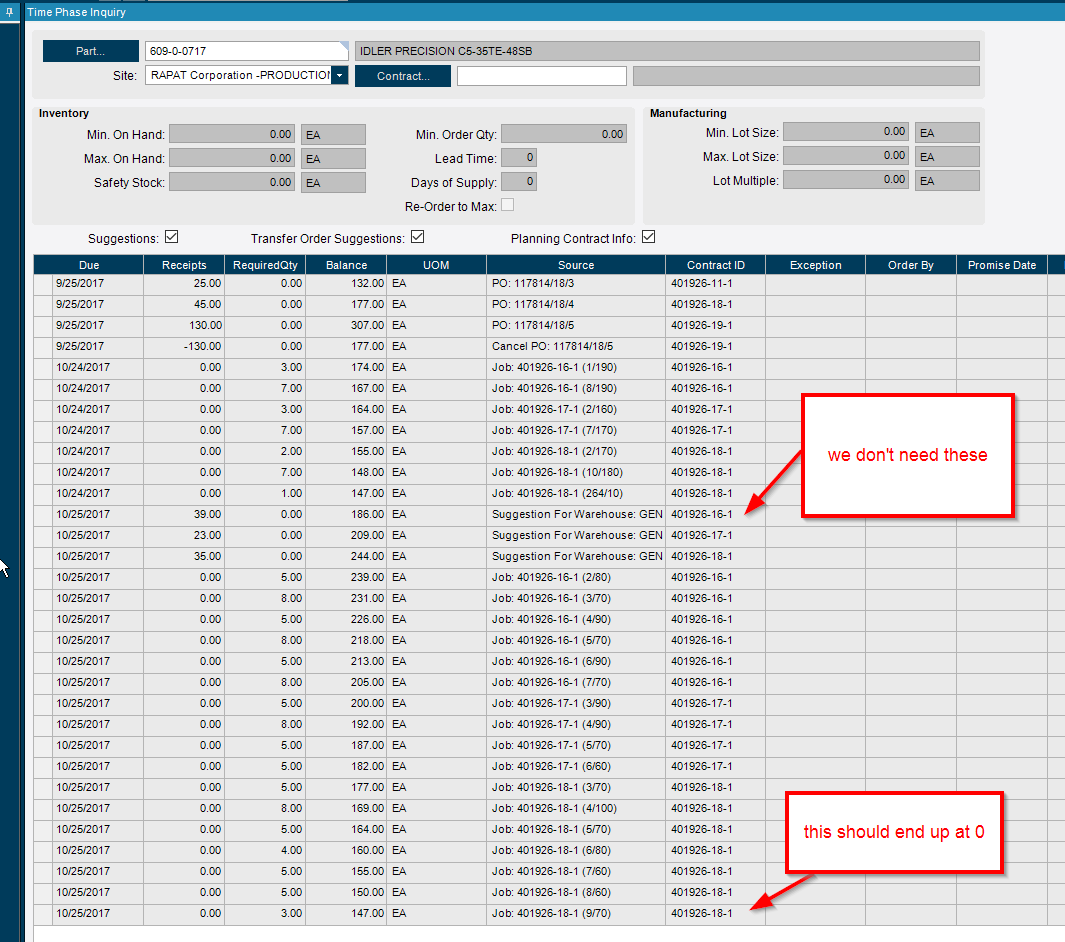

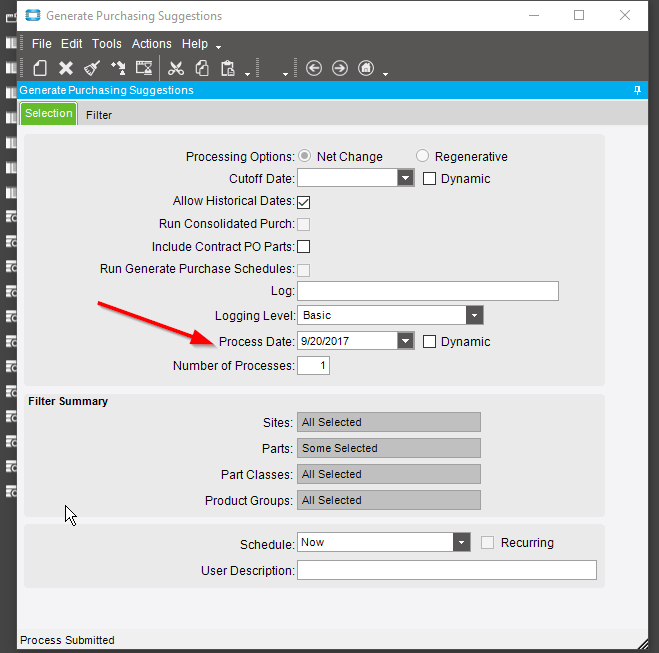

So I am trying to figure out why the system is making duplicate suggestions. These are related to part purchased on a planning contract. There is something to do with the dates, but I can’t figure out where it’s getting the numbers from. I added a note in the log where the system is created a change suggestion, then jumping to a date, and creating new suggestions. Ones that aren’t needed. If I push out the process date on the suggestion window, these duplicates will go away, but they come back again whenever suggestions are run normally. So where do I look to set the system to look at all future demand and calculate suggestions based on that. (we are custom engineered to order, so we don’t have any standing orders or anything out more than 6 months, so looking to infinity is a big deal for our business). If anyone can give me a hint on what is affecting this, or can educate me on purchase suggestion generation, that would be greatly appreciated.

**Full disclosure, we do not use scheduling properly in our system. We just slam and order in there, and if there is a suggestion to buy something, the purchaser buys it, irregardless of due dates. I know it’s a dumb way to run a business but you learn to stop fighting fights you won’t win.

Here’s the log for a specific part that is having problems. I made a note where jumps ahead to a future date. I don’t know why it picked that date, or why it ignores everything else behind it.

Lead times for this part are set to 0 if that makes any difference.

Wednesday, September 20, 2017 11:59:05

11:59:05 MRP Net Change process 1 begin - Ver wle-5-16-16 Run Date 9/20/2017 12:00:00 AM.

11:59:05 ------------------------------------------------------------

11:59:05 Cut Off Date -> 9/20/2027 12:00:00 AM

11:59:05 Schedule Start Date -> 9/20/2017 12:00:00 AM

11:59:05 Run Finite Scheduling -> True

11:59:05 Ignore Constrained Materials -> False

11:59:05 Allow Historical Dates -> True

11:59:05 Use Production Preparation Buffer -> True

11:59:05 Sort Level 0 MRP Jobs by Date -> False

11:59:05 Recycle MRP Jobs -> False

11:59:05 Site List -> MfgSys

11:59:05 ------------------------------------------------------------

11:59:05 Process Control Queue

11:59:05 Group -> Delete; Queue -> DeleteAllPO; Type -> Default; Finite -> False

11:59:05 Check List -> DeleteAllPO; Last Group -> False

11:59:05 Group -> NonPart; Queue -> Part; Type -> Part; Finite -> False

11:59:05 Check List -> Part; Last Group -> False

11:59:05 Group -> Part; Queue -> Part; Type -> Part; Finite -> False

11:59:05 Check List -> Part; Last Group -> True

11:59:05 ------------------------------------------------------------

11:59:05 Starting Part Level: 3-0. Wait Time 00h:00m:00s:000ms, Parts 0, Jobs 0

11:59:05 Processing Part:609-0-0717. V600

11:59:05 Processing Part:609-0-0717

11:59:05 Parameters: Receive Time -> 0; Planning Fence -> 0; Delta In -> 0; Delta Out -> 0; Lead Time CutOff -> , Use Dynamic DOS -> False, Allow Consume Min -> False

11:59:05 Deleting suggestions

11:59:05 Processing non-stock transactions for Part:609-0-0717.

11:59:05 Processing stock transactions for Part:609-0-0717.

11:59:05 Beginning Balance 0

11:59:05 Processing Part:609-0-0717

11:59:05 Parameters: Receive Time -> 0; Planning Fence -> 0; Delta In -> 0; Delta Out -> 0; Lead Time CutOff -> , Use Dynamic DOS -> False, Allow Consume Min -> False

11:59:05 Deleting suggestions

11:59:05 Processing non-stock transactions for Part:609-0-0717.

11:59:05 Processing stock transactions for Part:609-0-0717.

11:59:05 Beginning Balance 0

11:59:05 Date changed, process date

11:59:05 DoSuggestions, prev over quantity is:0.00000000.

11:59:05 DoSuggestion, Remaining is:25.00000000.

11:59:05 DoSuggestions - BuildLookAhead, skiptodate is:9/25/2017 12:00:00 AM, prev over quantity is: 0.00000000, cutoff quantity is: 25.00000000.

11:59:05 BuildLookAhead - starting date:9/25/2017 12:00:00 AM, prev over qty:0.00000000, cutoff qty:25.00000000.

11:59:05 DoSuggestions - days of supply: 0

11:59:05 DoSuggestions - process supply partdtl, remaining quantity is:25.00000000.

11:59:05 DoSuggestions - process supply partdtl, Part:609-0-0717, on date:9/25/2017 12:00:00 AM, quantity:25.00000000.

11:59:05 Creating PO change suggestion for PO:117814/18/2 Rsn:C Date:9/25/2017 12:00:00 AM Qty:0

11:59:05 DoSuggestions - supply cancelled, balance is:0.00000000.

11:59:05 DoSuggestions - skip date to:9/25/2017 12:00:00 AM.

11:59:05 Processing Part:609-0-0717

11:59:05 Parameters: Receive Time -> 0; Planning Fence -> 0; Delta In -> 0; Delta Out -> 0; Lead Time CutOff -> , Use Dynamic DOS -> False, Allow Consume Min -> False

11:59:05 Deleting suggestions

11:59:05 Processing non-stock transactions for Part:609-0-0717.

11:59:05 Processing stock transactions for Part:609-0-0717.

11:59:05 Beginning Balance 0

11:59:05 Date changed, process date

11:59:05 DoSuggestions, prev over quantity is:0.00000000.

11:59:05 DoSuggestion, Remaining is:25.00000000.

11:59:05 DoSuggestions - BuildLookAhead, skiptodate is:9/25/2017 12:00:00 AM, prev over quantity is: 0.00000000, cutoff quantity is: 25.00000000.

11:59:05 BuildLookAhead - starting date:9/25/2017 12:00:00 AM, prev over qty:0.00000000, cutoff qty:25.00000000.

11:59:05 DoSuggestions - days of supply: 0

11:59:05 DoSuggestions - process supply partdtl, remaining quantity is:25.00000000.

11:59:05 DoSuggestions - process supply partdtl, Part:609-0-0717, on date:9/25/2017 12:00:00 AM, quantity:25.00000000.

11:59:05 Creating PO change suggestion for PO:117814/18/3 Rsn:C Date:9/25/2017 12:00:00 AM Qty:0

11:59:05 DoSuggestions - supply cancelled, balance is:0.00000000.

11:59:05 DoSuggestions - skip date to:9/25/2017 12:00:00 AM.

11:59:05 Processing Part:609-0-0717

11:59:05 Parameters: Receive Time -> 0; Planning Fence -> 0; Delta In -> 0; Delta Out -> 0; Lead Time CutOff -> , Use Dynamic DOS -> False, Allow Consume Min -> False

11:59:05 Deleting suggestions

11:59:05 Processing non-stock transactions for Part:609-0-0717.

11:59:05 Processing stock transactions for Part:609-0-0717.

11:59:05 Beginning Balance 0

11:59:05 Date changed, process date

11:59:05 Date changed, process date 9/25/2017 12:00:00 AM

11:59:05 over re-order, DoSuggestion…

11:59:05 DoSuggestions, prev over quantity is:0.00000000.

11:59:05 DoSuggestion, Remaining is:49.00000000.

11:59:05 DoSuggestions - BuildLookAhead, skiptodate is:9/25/2017 12:00:00 AM, prev over quantity is: 0.00000000, cutoff quantity is: 49.00000000.

11:59:05 BuildLookAhead - starting date:9/25/2017 12:00:00 AM, prev over qty:0.00000000, cutoff qty:49.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/24/2017 12:00:00 AM, qty:3.00000000.

11:59:05 BuildLookAhead - found first req on::10/24/2017 12:00:00 AM.

11:59:05 BuildLookAhead - on date 10/24/2017 12:00:00 AM, net req is 3.00000000, accu req is 3.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/24/2017 12:00:00 AM, qty:7.00000000.

11:59:05 BuildLookAhead - on date 10/24/2017 12:00:00 AM, net req is 10.00000000, accu req is 10.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:5.00000000.

11:59:05 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 5.00000000, accu req is 15.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:8.00000000.

11:59:05 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 13.00000000, accu req is 23.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:5.00000000.

11:59:05 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 18.00000000, accu req is 28.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:8.00000000.

11:59:05 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 26.00000000, accu req is 36.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:5.00000000.

11:59:05 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 31.00000000, accu req is 41.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:8.00000000.

11:59:05 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 39.00000000, accu req is 49.00000000.

11:59:05 DoSuggestions - days of supply: 0

11:59:05 DoSuggestions - process supply partdtl, remaining quantity is:49.00000000.

11:59:05 DoSuggestions - process supply partdtl, Part:609-0-0717, on date:9/25/2017 12:00:00 AM, quantity:49.00000000.

11:59:05 Creating PO change suggestion for PO:117801/15/1 Rsn:P Date:10/24/2017 12:00:00 AM Qty:0 ********* why is it doing this?? How do I get it to stop that??

11:59:05 DoSuggestions - date is changed to:10/24/2017 12:00:00 AM.

11:59:05 DoSuggestions - qty is going to be changed to:10.00000000.

11:59:05 POChangeSuggestion

11:59:05 Creating PO change suggestion for PO:117801/15/1 Rsn:R Date:10/24/2017 12:00:00 AM Qty:10.00000000

11:59:05 DoSuggestions - skip date to:10/24/2017 12:00:00 AM.

11:59:05 DoSuggestions - after qty increase/decrease, balance is:0.00000000.

11:59:05 After DoSuggestions, balance is:0.00000000.

11:59:05 Date changed, process date 10/24/2017 12:00:00 AM

11:59:05 Creating new PO suggestion for Part:609-0-0717 Date: 10/25/2017 12:00:00 AM Quantity: 39.00000000 Number: 0

11:59:05 Done with New Suggestion transaction

11:59:05 Processing Part:609-0-0717

11:59:05 Parameters: Receive Time -> 0; Planning Fence -> 0; Delta In -> 0; Delta Out -> 0; Lead Time CutOff -> , Use Dynamic DOS -> False, Allow Consume Min -> False

11:59:05 Deleting suggestions

11:59:05 Processing non-stock transactions for Part:609-0-0717.

11:59:05 Processing stock transactions for Part:609-0-0717.

11:59:05 Beginning Balance 0

11:59:05 Date changed, process date

11:59:05 Date changed, process date 9/25/2017 12:00:00 AM

11:59:05 over re-order, DoSuggestion…

11:59:05 DoSuggestions, prev over quantity is:0.00000000.

11:59:05 DoSuggestion, Remaining is:33.00000000.

11:59:05 DoSuggestions - BuildLookAhead, skiptodate is:9/25/2017 12:00:00 AM, prev over quantity is: 0.00000000, cutoff quantity is: 33.00000000.

11:59:05 BuildLookAhead - starting date:9/25/2017 12:00:00 AM, prev over qty:0.00000000, cutoff qty:33.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/24/2017 12:00:00 AM, qty:3.00000000.

11:59:05 BuildLookAhead - found first req on::10/24/2017 12:00:00 AM.

11:59:05 BuildLookAhead - on date 10/24/2017 12:00:00 AM, net req is 3.00000000, accu req is 3.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/24/2017 12:00:00 AM, qty:7.00000000.

11:59:05 BuildLookAhead - on date 10/24/2017 12:00:00 AM, net req is 10.00000000, accu req is 10.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:5.00000000.

11:59:05 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 5.00000000, accu req is 15.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:8.00000000.

11:59:05 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 13.00000000, accu req is 23.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:5.00000000.

11:59:05 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 18.00000000, accu req is 28.00000000.

11:59:05 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:5.00000000.

11:59:05 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 23.00000000, accu req is 33.00000000.

11:59:05 DoSuggestions - days of supply: 0

11:59:05 DoSuggestions - process supply partdtl, remaining quantity is:33.00000000.

11:59:05 DoSuggestions - process supply partdtl, Part:609-0-0717, on date:9/25/2017 12:00:00 AM, quantity:33.00000000.

11:59:05 Creating PO change suggestion for PO:117801/15/2 Rsn:P Date:10/24/2017 12:00:00 AM Qty:0

11:59:05 DoSuggestions - date is changed to:10/24/2017 12:00:00 AM.

11:59:05 DoSuggestions - qty is going to be changed to:10.00000000.

11:59:05 POChangeSuggestion

11:59:05 Creating PO change suggestion for PO:117801/15/2 Rsn:R Date:10/24/2017 12:00:00 AM Qty:10.00000000

11:59:05 DoSuggestions - skip date to:10/24/2017 12:00:00 AM.

11:59:05 DoSuggestions - after qty increase/decrease, balance is:0.00000000.

11:59:05 After DoSuggestions, balance is:0.00000000.

11:59:05 Date changed, process date 10/24/2017 12:00:00 AM

11:59:05 Creating new PO suggestion for Part:609-0-0717 Date: 10/25/2017 12:00:00 AM Quantity: 23.00000000 Number: 0

11:59:05 Done with New Suggestion transaction

11:59:05 Processing Part:609-0-0717

11:59:05 Parameters: Receive Time -> 0; Planning Fence -> 0; Delta In -> 0; Delta Out -> 0; Lead Time CutOff -> , Use Dynamic DOS -> False, Allow Consume Min -> False

11:59:05 Deleting suggestions

11:59:05 Processing non-stock transactions for Part:609-0-0717.

11:59:06 Processing stock transactions for Part:609-0-0717.

11:59:06 Beginning Balance 0

11:59:06 Date changed, process date

11:59:06 Date changed, process date 9/25/2017 12:00:00 AM

11:59:06 over re-order, DoSuggestion…

11:59:06 DoSuggestions, prev over quantity is:0.00000000.

11:59:06 DoSuggestion, Remaining is:45.00000000.

11:59:06 DoSuggestions - BuildLookAhead, skiptodate is:9/25/2017 12:00:00 AM, prev over quantity is: 0.00000000, cutoff quantity is: 45.00000000.

11:59:06 BuildLookAhead - starting date:9/25/2017 12:00:00 AM, prev over qty:0.00000000, cutoff qty:45.00000000.

11:59:06 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/24/2017 12:00:00 AM, qty:2.00000000.

11:59:06 BuildLookAhead - found first req on::10/24/2017 12:00:00 AM.

11:59:06 BuildLookAhead - on date 10/24/2017 12:00:00 AM, net req is 2.00000000, accu req is 2.00000000.

11:59:06 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/24/2017 12:00:00 AM, qty:7.00000000.

11:59:06 BuildLookAhead - on date 10/24/2017 12:00:00 AM, net req is 9.00000000, accu req is 9.00000000.

11:59:06 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/24/2017 12:00:00 AM, qty:1.00000000.

11:59:06 BuildLookAhead - on date 10/24/2017 12:00:00 AM, net req is 10.00000000, accu req is 10.00000000.

11:59:06 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:5.00000000.

11:59:06 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 5.00000000, accu req is 15.00000000.

11:59:06 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:8.00000000.

11:59:06 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 13.00000000, accu req is 23.00000000.

11:59:06 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:5.00000000.

11:59:06 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 18.00000000, accu req is 28.00000000.

11:59:06 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:4.00000000.

11:59:06 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 22.00000000, accu req is 32.00000000.

11:59:06 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:5.00000000.

11:59:06 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 27.00000000, accu req is 37.00000000.

11:59:06 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:5.00000000.

11:59:06 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 32.00000000, accu req is 42.00000000.

11:59:06 BuildLookAhead - process req partdtl, Part:609-0-0717, date:10/25/2017 12:00:00 AM, qty:3.00000000.

11:59:06 BuildLookAhead - on date 10/25/2017 12:00:00 AM, net req is 35.00000000, accu req is 45.00000000.

11:59:06 DoSuggestions - days of supply: 0

11:59:06 DoSuggestions - process supply partdtl, remaining quantity is:45.00000000.

11:59:06 DoSuggestions - process supply partdtl, Part:609-0-0717, on date:9/25/2017 12:00:00 AM, quantity:45.00000000.

11:59:06 Creating PO change suggestion for PO:117814/18/4 Rsn:P Date:10/24/2017 12:00:00 AM Qty:0

11:59:06 DoSuggestions - date is changed to:10/24/2017 12:00:00 AM.

11:59:06 DoSuggestions - qty is going to be changed to:10.00000000.

11:59:06 POChangeSuggestion

11:59:06 Creating PO change suggestion for PO:117814/18/4 Rsn:R Date:10/24/2017 12:00:00 AM Qty:10.00000000

11:59:06 DoSuggestions - skip date to:10/24/2017 12:00:00 AM.

11:59:06 DoSuggestions - after qty increase/decrease, balance is:0.00000000.

11:59:06 After DoSuggestions, balance is:0.00000000.

11:59:06 Date changed, process date 10/24/2017 12:00:00 AM

11:59:06 Creating new PO suggestion for Part:609-0-0717 Date: 10/25/2017 12:00:00 AM Quantity: 35.00000000 Number: 0

11:59:06 Done with New Suggestion transaction

11:59:06 Processing Part:609-0-0717

11:59:06 Parameters: Receive Time -> 0; Planning Fence -> 0; Delta In -> 0; Delta Out -> 0; Lead Time CutOff -> , Use Dynamic DOS -> False, Allow Consume Min -> False

11:59:06 Deleting suggestions

11:59:06 Processing non-stock transactions for Part:609-0-0717.

11:59:06 Processing stock transactions for Part:609-0-0717.

11:59:06 Beginning Balance 0

11:59:06 Date changed, process date

11:59:06 DoSuggestions, prev over quantity is:0.00000000.

11:59:06 DoSuggestion, Remaining is:130.00000000.

11:59:06 DoSuggestions - BuildLookAhead, skiptodate is:9/25/2017 12:00:00 AM, prev over quantity is: 0.00000000, cutoff quantity is: 130.00000000.

11:59:06 BuildLookAhead - starting date:9/25/2017 12:00:00 AM, prev over qty:0.00000000, cutoff qty:130.00000000.

11:59:06 DoSuggestions - days of supply: 0

11:59:06 DoSuggestions - process supply partdtl, remaining quantity is:130.00000000.

11:59:06 DoSuggestions - process supply partdtl, Part:609-0-0717, on date:9/25/2017 12:00:00 AM, quantity:130.00000000.

11:59:06 Creating PO change suggestion for PO:117814/18/5 Rsn:C Date:9/25/2017 12:00:00 AM Qty:0

11:59:06 DoSuggestions - supply cancelled, balance is:0.00000000.

11:59:06 DoSuggestions - skip date to:9/25/2017 12:00:00 AM.

11:59:06 Done with Part 609-0-0717