Hello!

Sorry for the delay. I wanted to confirm some information and look into the Crystal report itself.

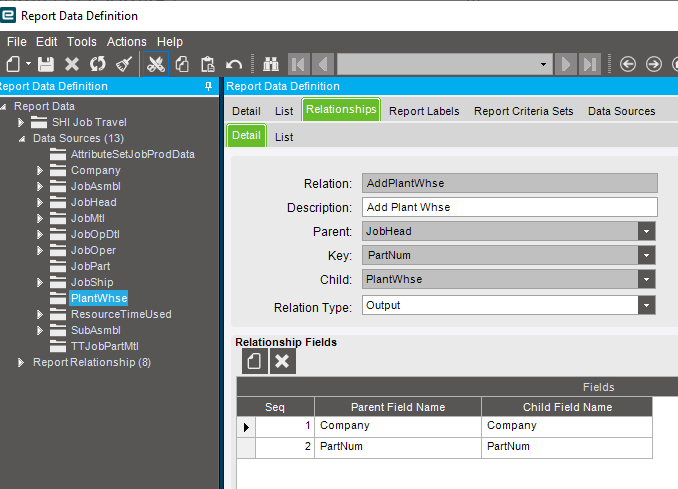

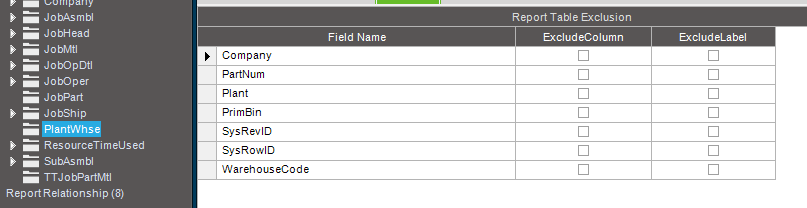

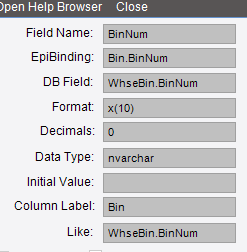

Ah, so the material movers know where to send the finished part. Do you only have one Warehouse then? If not, what did the Crystal Report do?

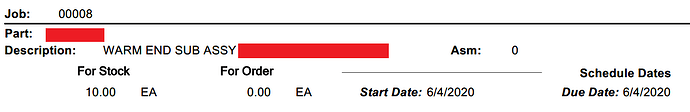

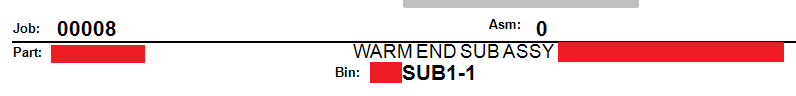

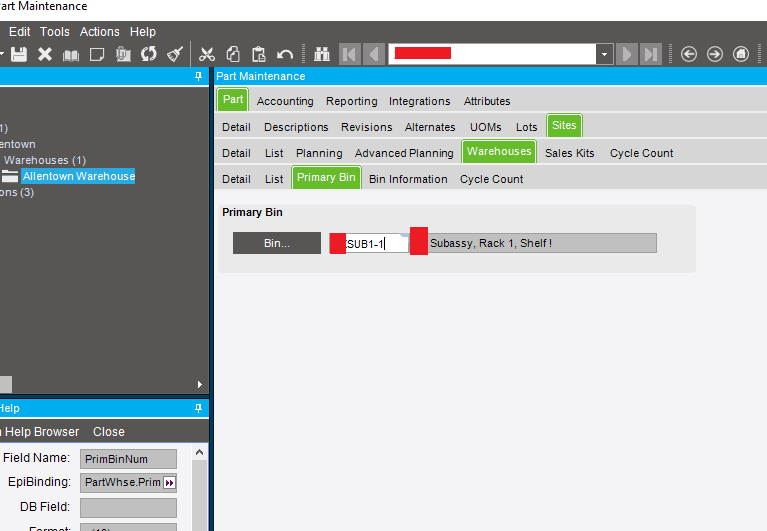

We have multiple warehouses, but I think the people using it only rely on one. I asked one of our users to explain what happens: “Parts go to the default bin in the part master, under warehouse, primary bin and they backflush from the default bin (based on when the job was cut).”

Here is the Crystal report:

JobTravBin.rpt (38 KB)

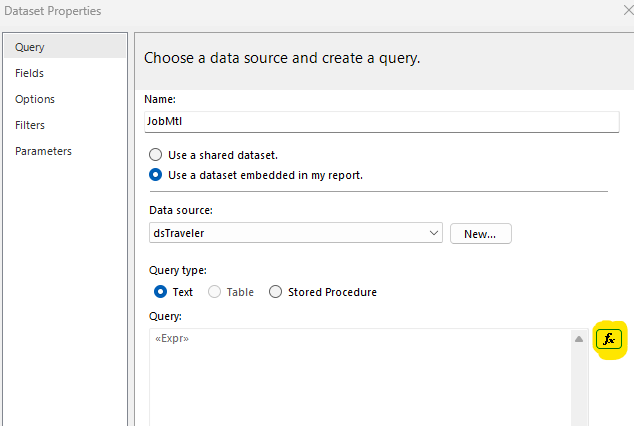

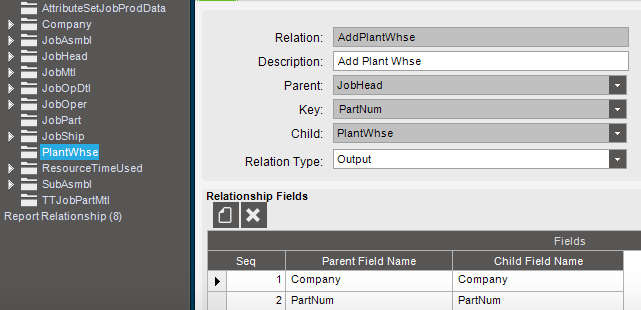

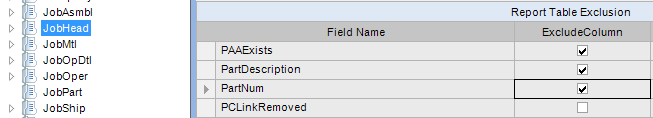

But I don’t see it being referenced as a new table join in your RDL query. I know you said the below was the “out-of-the-box query”… so you’d have to add the bold text below:

I did as you recommended and got an “The CommandText expression for the query ‘JobHead’ contains an error: [BC30205] End of statement expected.” error when saved. I probably did it incorrectly…:

="SELECT T1.DueDate,T1.IUM,T1.ProdQty,T1.ReqDueDate,T1.StartDate,T1.Calc_MultiJobParts,T1.Calc_OrderQty,T1.Calc_StockQty, T2.AssemblySeq,T2.BomSequence,T2.Company,T2.[Description],T2.DrawNum,T2.IUM as JobAsmbl_IUM,T2.JobNum,T2.OverRunQty,T2.PartNum,T2.PullQty,T2.RequiredQty,T2.RevisionNum,T2.Calc_BCAsmSeq,T2.Calc_BCJobNum,T2.Calc_BCPartNum,T2.Calc_BCRevNum,T2.Calc_comment, T2.Calc_AttributeSetShortDescription, T3.CommentText,T3.Instructions,T3.DaysOut,T3.DueDate as JobOper_DueDate,T3.EstProdHours,T3.EstSetHours,T3.Machines,T3.OpCode,T3.OpDesc,T3.OprSeq,T3.PrimaryProdOpDtl,T3.PrimarySetupOpDtl,T3.ProdStandard,T3.RunQty,T3.StartDate as JobOper_StartDate,T3.StdFormat,T3.Calc_BCOpCode,T3.Calc_BCOprSeq,T3.Calc_DispStatus,T3.Calc_OPText,T3.Calc_OPType,T3.Calc_PurPoint,T3.Calc_VendorId,T3.Calc_VendorName,T3.OpCode_OpDesc, T4.CapabilityID,T4.ConcurrentCapacity,T4.DailyProdRate,T4.OpDtlSeq,T4.ProdCrewSize,T4.ResourceGrpID,T4.ResourceID,T4.SetUpCrewSize,T4.SetupOrProd,T4.Calc_BCCapabilityID,T4.Calc_BCResGrpID,T4.Calc_BCResourceID,T4.Calc_CapbltyDesc,T4.Calc_ResDesc,T4.Calc_ResGrpDesc,T4.Calc_SchedResDesc,T4.Calc_SchedResGrpDesc,T4.Calc_SchedResGrpID,T4.Calc_SchedResID, T5.ResourceGrpID as ResourceTimeUsed_ResourceGrpID,T5.ResourceID as ResourceTimeUsed_ResourceID,T5.WhatIf,T6.PrimBin

FROM JobHead_" + Parameters!TableGuid.Value + " T1

LEFT OUTER JOIN JobAsmbl_" + Parameters!TableGuid.Value + " T2

ON T1.Company = T2.Company AND T1.JobNum = T2.JobNum

LEFT OUTER JOIN JobOper_" + Parameters!TableGuid.Value + " T3

ON T2.Company = T3.Company AND T2.JobNum = T3.JobNum AND T2.AssemblySeq = T3.AssemblySeq

LEFT OUTER JOIN JobOpDtl_" + Parameters!TableGuid.Value + " T4

ON T3.Company = T4.Company AND T3.JobNum = T4.JobNum AND T3.AssemblySeq = T4.AssemblySeq AND T3.OprSeq = T4.OprSeq

LEFT OUTER JOIN ResourceTimeUsed_" + Parameters!TableGuid.Value + " T5

ON T4.Company = T5.Company AND T4.JobNum = T5.JobNum AND T4.AssemblySeq = T5.AssemblySeq AND T4.OprSeq = T5.OprSeq AND T4.OpDtlSeq = T5.OpDtlSeq"

LEFT OUTER JOIN PlantWhse_" + Parameters!TableGuid.Value + " T6

ON T1.Company = T6.Company AND T1.PartNum = T6.PartNum"